Menu

Close

Menu

Close

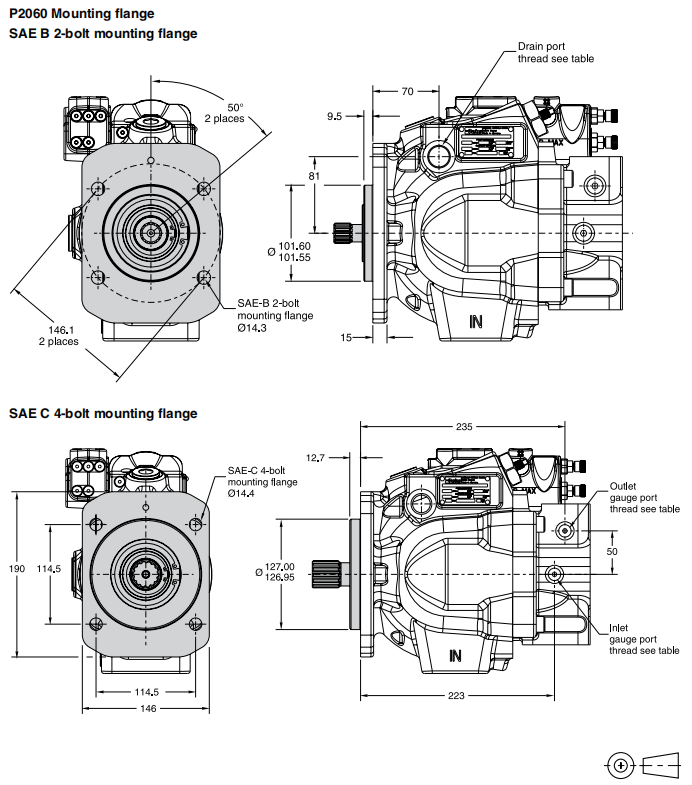

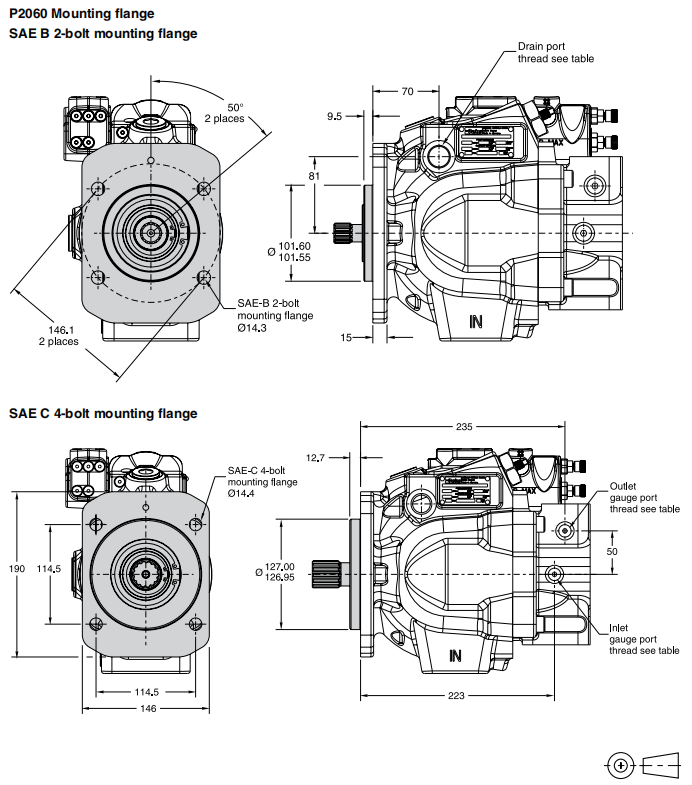

The Parker P2 pump has a displacement of 60 cc/rev – 145cc/rev,

high pressure variable displacement swash plate piston pump for open circuit mobile hydraulic systems.

When it comes to savings on installation costs coupled with high productivity and power density, they are a good choice.

Contact Poocca Hydraulics Suppliers today.

P2 piston pump model:P060,P2075,P2105,P2145

PARKER P2 PISTON PUMP TECHNICAL FEATURES

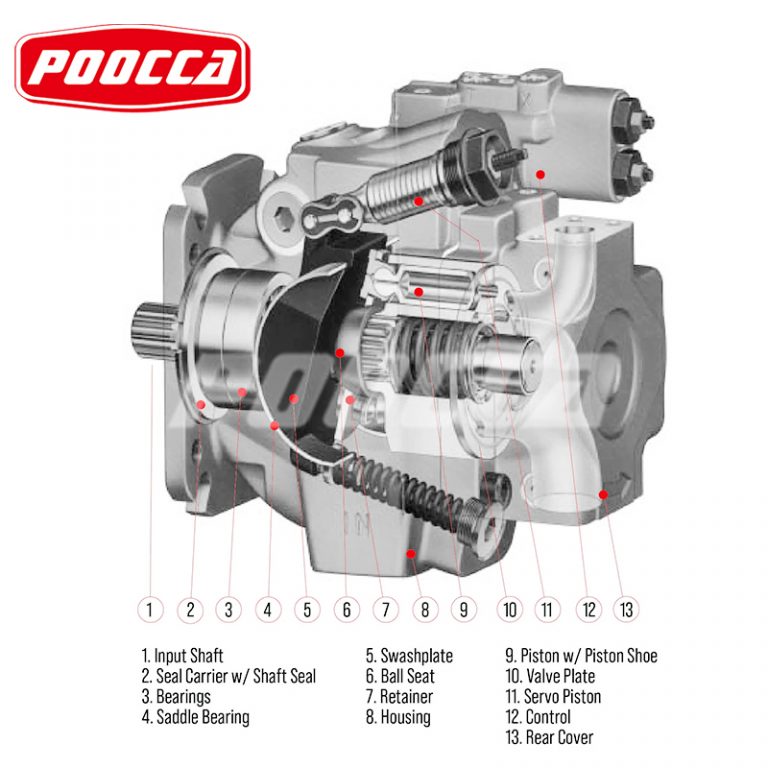

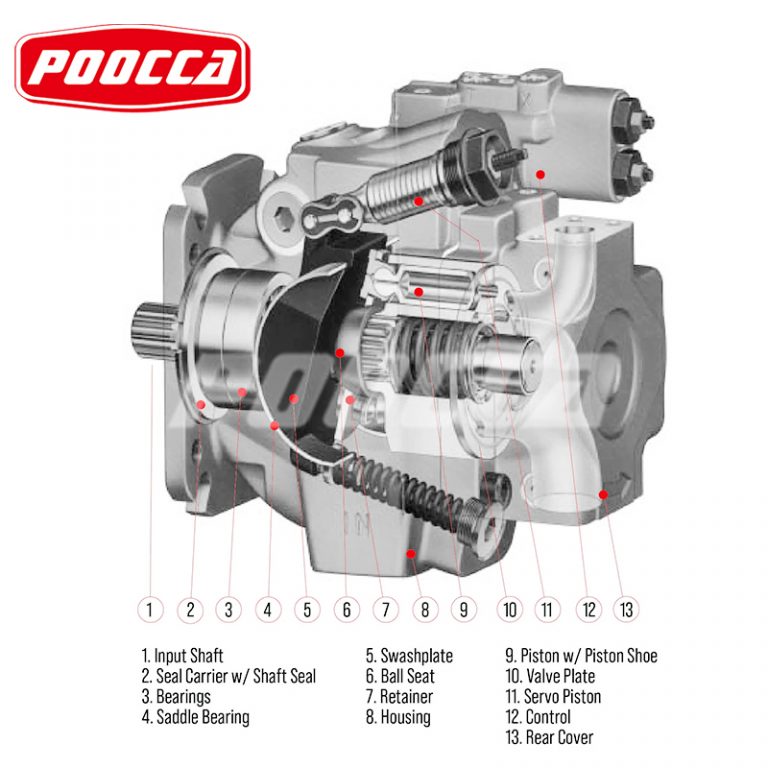

Compact Design:

The Parker P2 PISTON PUMP features a compact and space-saving design, making it ideal for applications where space is limited. Its small footprint makes it easier to integrate into a variety of hydraulic systems without compromising performance.

Low Noise:

The P2 PISTON PUMP is designed for quiet operation, minimizing noise levels during use. This is particularly beneficial in environments where noise reduction is important, helping to create a more comfortable working atmosphere and reducing noise pollution.

Easy to Maintain:

The Parker P2 PISTON PUMP is designed with easy maintenance in mind, simplifying service and maintenance. Its user-friendly design allows for quick, hassle-free maintenance, reducing downtime and increasing overall system productivity.

Long-Lasting Durability:

The P2 PISTON PUMP is built to last. Its durable components, such as high-quality bearings and seals, ensure a long service life even under high pressure conditions, reducing the need for frequent replacement and minimizing operating costs.

Flexible:

The Parker P2 PISTON PUMP has excellent flexibility, making it suitable for a wide range of applications. It can be customized to specific needs, providing the versatility needed to work in mobile and industrial environments.

Easy to Install:

Thanks to its thoughtful design, the Parker P2 plunger pump is easy to install, minimizing setup time and reducing the complexity of integration into existing systems. This easy installation feature allows for faster project completion and reduces installation-related challenges.

High Self-Priming Speed:

The P2 plunger pump has a high self-priming speed, enabling it to quickly build pressure and begin operating efficiently. This feature is particularly beneficial in applications where fast system startup is critical, improving overall system responsiveness.

| Parker Pump Frame size | P2060 | P2075 | P2105 | P2145 |

| Max displacement cm³/rev [cuin/rev] | 60 | 75 | 105 | 145 |

| 3.66 | 4.58 | 6.41 | 8.85 | |

| Self-priming speed at 1 bar/14.5 psi abs. inlet pressure [rpm] | 2800 | 2500 | 2300 | 2200 |

| Max continuous pressure bar [psi] | 320 | 320 | 320 | 320 |

| 4600 | 4600 | 4600 | 4600 | |

| Peak pressure bar [psi] | 370 | 370 | 370 | 370 |

| 5365 | 5365 | 5365 | 5365 | |

| Minimum Inlet Pressure barabs at max speed [in Hg vacuum] | 0.8 | 0.8 | 0.8 | 0.8 |

| 5.8 | 5.8 | 5.8 | 5.8 | |

| Maximum Inlet Pressure bar [psi] | 10 | 10 | 10 | 10 |

| 145 | 145 | 145 | 145 | |

| Maximum Case Drain Pressure bar continuous psi | 0.5 | 0.5 | 0.5 | 0.5 |

| 7.75 | 7.75 | 7.75 | 7.75 | |

| Noise level at full flow, 1800 rpm, and 250 bar (3600 psi) [dbA] | ||||

| 74 | 76 | 78 | 80 | |

| Weight with load sense control kg [lbs] | 37 | 44 | 63 | 78 |

| 81 | 97 | 139 | 172 | |

| Mass moment of inertia kg m2 (about axis of shaft) | 0.0061 | 0.0101 | 0.0168 | 0.0241 |

Recommended oils for Parker P2 hydraulic piston pumps:

Standard mineral oils

High quality hydraulic oils (HLP oils)

Biodegradable hydraulic oils

Synthetic hydraulic oils

Fuel resistant, including water-based oils

Important note:

When using water-based oils, system pressure must be limited to a maximum of 210 bar, which may reduce the bearing life of Parker P2 axial piston pumps by up to 25%.

Viscosity:

Minimum viscosity for short-term operation: 10 mm²/s (cSt)

Typical operating viscosity: 15 to 40 mm²/s (cSt)

Maximum viscosity for short-term operation: 1000 mm²/s (cSt)

Filtration: To improve pump performance and extend system life, effective filtration is essential to prevent contamination. Fluid cleanliness should comply with ISO4406 standards and filter element quality should comply with relevant ISO specifications.

Recommended filtration grade: ISO 4406 code 21/18/14.

Seals: Check the hydraulic oil specifications for Parker P2 piston pumps and verify chemical compatibility with seal materials. Also, make sure the seal material’s temperature range matches the system’s operating and environmental conditions.

N: Clear, single shaft extension seal (-40 to +90°C)

D: Sun, dual shaft extension seal (-40 to +90°C)

V: Fluorocarbon, single shaft seal (-15 to +150°C)

T: Fluorocarbon, dual shaft seal (-15 to +150°C)

Note:

The maximum oil temperature in Parker’s P2 plunger pumps is measured at the pump drain port and can be up to 20°C above the temperature in the reservoir.

Axial/Radial Loads:

Equipment subject to radial loads requires external bearing support as they cannot support axial loads.

At Poocca Hydraulics Suppliers, we are more than just a hydraulics factory, we are your partner in hydraulic excellence. Through seamless integration of R&D, manufacturing, maintenance and sales, we offer a wide range of hydraulic pumps, motors and valves to meet the needs of various industries.

Our expertise

From mining machinery to shipbuilding, engineering and power plants, our products and technologies leave their mark in multiple sectors. We specialize in hydraulic system project modifications, aiming to achieve localization to reduce costs and replace imported components. In addition, our services include hydraulic system upgrades, optimization and energy-saving enhancements.

best selling products

Discover our best-selling products carefully designed to meet the needs of modern industry:

Piston pump: A10VSO, A11VSO, A4VSO, A4VG, A7VO, PVH, PV series, etc.

Gear pump: AZPF, ALP, 1P, 0.25-0.5, PGP, SGP, HG series, etc.

Vane pumps: VQ, T6T7, PV2R series, including single pump, double pump and triple pump configurations.

Motor: A2FM, A2FE, A6VM, 2000 series, 6000 series, etc.

Your solution, our priority

At Poocca, we are committed to providing timely and tailor-made solutions to meet your hydraulic requirements. Whether consulting, project execution or product procurement, our team is committed to delivering excellence every step of the way.

keep in touch

Ready to upgrade your hydraulic system? Feel free to contact us any time. Your satisfaction is our top priority and we will make sure you get exactly what you need. Please send your request to poocca hydraulics immediately and we will reply to you as soon as possible.

PARKER P2 PISTON PUMP TECHNICAL FEATURES

Compact Design:

The Parker P2 PISTON PUMP features a compact and space-saving design, making it ideal for applications where space is limited. Its small footprint makes it easier to integrate into a variety of hydraulic systems without compromising performance.

Low Noise:

The P2 PISTON PUMP is designed for quiet operation, minimizing noise levels during use. This is particularly beneficial in environments where noise reduction is important, helping to create a more comfortable working atmosphere and reducing noise pollution.

Easy to Maintain:

The Parker P2 PISTON PUMP is designed with easy maintenance in mind, simplifying service and maintenance. Its user-friendly design allows for quick, hassle-free maintenance, reducing downtime and increasing overall system productivity.

Long-Lasting Durability:

The P2 PISTON PUMP is built to last. Its durable components, such as high-quality bearings and seals, ensure a long service life even under high pressure conditions, reducing the need for frequent replacement and minimizing operating costs.

Flexible:

The Parker P2 PISTON PUMP has excellent flexibility, making it suitable for a wide range of applications. It can be customized to specific needs, providing the versatility needed to work in mobile and industrial environments.

Easy to Install:

Thanks to its thoughtful design, the Parker P2 plunger pump is easy to install, minimizing setup time and reducing the complexity of integration into existing systems. This easy installation feature allows for faster project completion and reduces installation-related challenges.

High Self-Priming Speed:

The P2 plunger pump has a high self-priming speed, enabling it to quickly build pressure and begin operating efficiently. This feature is particularly beneficial in applications where fast system startup is critical, improving overall system responsiveness.

| Parker Pump Frame size | P2060 | P2075 | P2105 | P2145 |

| Max displacement cm³/rev [cuin/rev] | 60 | 75 | 105 | 145 |

| 3.66 | 4.58 | 6.41 | 8.85 | |

| Self-priming speed at 1 bar/14.5 psi abs. inlet pressure [rpm] | 2800 | 2500 | 2300 | 2200 |

| Max continuous pressure bar [psi] | 320 | 320 | 320 | 320 |

| 4600 | 4600 | 4600 | 4600 | |

| Peak pressure bar [psi] | 370 | 370 | 370 | 370 |

| 5365 | 5365 | 5365 | 5365 | |

| Minimum Inlet Pressure barabs at max speed [in Hg vacuum] | 0.8 | 0.8 | 0.8 | 0.8 |

| 5.8 | 5.8 | 5.8 | 5.8 | |

| Maximum Inlet Pressure bar [psi] | 10 | 10 | 10 | 10 |

| 145 | 145 | 145 | 145 | |

| Maximum Case Drain Pressure bar continuous psi | 0.5 | 0.5 | 0.5 | 0.5 |

| 7.75 | 7.75 | 7.75 | 7.75 | |

| Noise level at full flow, 1800 rpm, and 250 bar (3600 psi) [dbA] | ||||

| 74 | 76 | 78 | 80 | |

| Weight with load sense control kg [lbs] | 37 | 44 | 63 | 78 |

| 81 | 97 | 139 | 172 | |

| Mass moment of inertia kg m2 (about axis of shaft) | 0.0061 | 0.0101 | 0.0168 | 0.0241 |

Recommended oils for Parker P2 hydraulic piston pumps:

Standard mineral oils

High quality hydraulic oils (HLP oils)

Biodegradable hydraulic oils

Synthetic hydraulic oils

Fuel resistant, including water-based oils

Important note:

When using water-based oils, system pressure must be limited to a maximum of 210 bar, which may reduce the bearing life of Parker P2 axial piston pumps by up to 25%.

Viscosity:

Minimum viscosity for short-term operation: 10 mm²/s (cSt)

Typical operating viscosity: 15 to 40 mm²/s (cSt)

Maximum viscosity for short-term operation: 1000 mm²/s (cSt)

Filtration: To improve pump performance and extend system life, effective filtration is essential to prevent contamination. Fluid cleanliness should comply with ISO4406 standards and filter element quality should comply with relevant ISO specifications.

Recommended filtration grade: ISO 4406 code 21/18/14.

Seals: Check the hydraulic oil specifications for Parker P2 piston pumps and verify chemical compatibility with seal materials. Also, make sure the seal material’s temperature range matches the system’s operating and environmental conditions.

N: Clear, single shaft extension seal (-40 to +90°C)

D: Sun, dual shaft extension seal (-40 to +90°C)

V: Fluorocarbon, single shaft seal (-15 to +150°C)

T: Fluorocarbon, dual shaft seal (-15 to +150°C)

Note:

The maximum oil temperature in Parker’s P2 plunger pumps is measured at the pump drain port and can be up to 20°C above the temperature in the reservoir.

Axial/Radial Loads:

Equipment subject to radial loads requires external bearing support as they cannot support axial loads.

At Poocca Hydraulics Suppliers, we are more than just a hydraulics factory, we are your partner in hydraulic excellence. Through seamless integration of R&D, manufacturing, maintenance and sales, we offer a wide range of hydraulic pumps, motors and valves to meet the needs of various industries.

Our expertise

From mining machinery to shipbuilding, engineering and power plants, our products and technologies leave their mark in multiple sectors. We specialize in hydraulic system project modifications, aiming to achieve localization to reduce costs and replace imported components. In addition, our services include hydraulic system upgrades, optimization and energy-saving enhancements.

best selling products

Discover our best-selling products carefully designed to meet the needs of modern industry:

Piston pump: A10VSO, A11VSO, A4VSO, A4VG, A7VO, PVH, PV series, etc.

Gear pump: AZPF, ALP, 1P, 0.25-0.5, PGP, SGP, HG series, etc.

Vane pumps: VQ, T6T7, PV2R series, including single pump, double pump and triple pump configurations.

Motor: A2FM, A2FE, A6VM, 2000 series, 6000 series, etc.

Your solution, our priority

At Poocca, we are committed to providing timely and tailor-made solutions to meet your hydraulic requirements. Whether consulting, project execution or product procurement, our team is committed to delivering excellence every step of the way.

keep in touch

Ready to upgrade your hydraulic system? Feel free to contact us any time. Your satisfaction is our top priority and we will make sure you get exactly what you need. Please send your request to poocca hydraulics immediately and we will reply to you as soon as possible.

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us using WeChat

Welcome to contact us via whatsapp