Menu

Close

Menu

Close

Hydraulic valves have a wide range of applications in modern engineering fields. They have many structural types and can be classified according to their functions and characteristics. Hydraulic valves can be divided into directional control valves, flow control valves and pressure control valves. These three major categories of hydraulic valves include many specific valve models, such as P40 P80 P120, Rexroth 4WE valve, DSG, HG vlave, DHA, KSO, MBP, 4WRZ ZDB, Vickers hydraulic valve DG4V, Yuken valve DFA DFB, etc.

Directional control valves are mainly used to control the flow direction of fluids to connect or disconnect various components in the system. They have high reliability and stability and are used in various types of engineering machinery.

The flow control valve is a valve that changes the fluid flow by adjusting the opening of the valve, thereby controlling the working speed of the system. The pressure control valve is mainly used to adjust the working pressure of the system to ensure that the equipment operates at the appropriate working pressure. This type of valve has significant advantages in pressure control.

Our manufacturing facility houses many CNC machines capable of producing high-quality hydraulic components and replacement parts.

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 1997 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts. With extensive experience in providing power transmission and drive solutions to hydraulic system users around the world, we have a strong reputation in the industry.

Over the past two decades, POOCCAHydraulics has continued to grow and innovate in the field of hydraulics. We have won the trust of domestic and foreign manufacturers and established strong corporate partnerships. Our annual export volume is up to US$16 million and exported to more than 100 countries. We have established long-term and stable cooperative relationships with dealers in more than 75 countries, including the United States, Indonesia, Mexico, Thailand, Russia and Brazil.

Hydraulic valves are an integral part of the transmission and control mechanism. The hydraulic valve is a key part of this system because it is responsible for regulating, controlling and stabilizing the flow of liquid, thereby achieving precise control of mechanical equipment.

The core function of a hydraulic valve is to regulate the flow and pressure of liquid in the hydraulic system. By changing the opening of the valve port and the working position of the valve, the hydraulic valve can control the flow direction and flow rate of the liquid, thereby controlling the movement, speed, and force of the mechanical equipment. Hydraulic valves are like “switches” or “regulators” in the hydraulic system, finely regulating the flow of liquid.

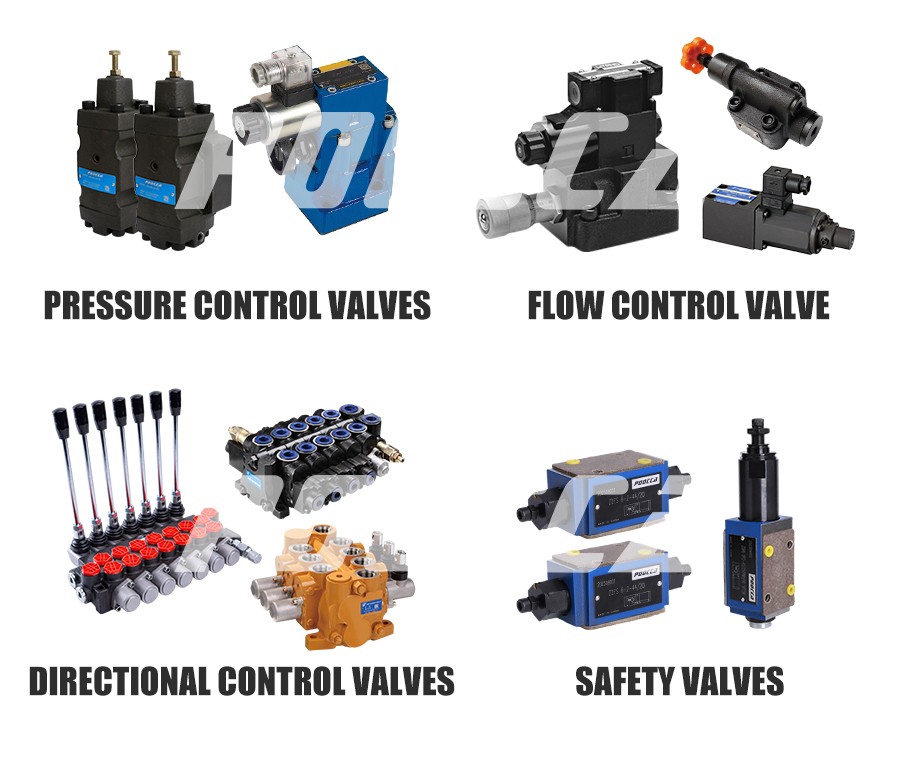

There are many types of POOCCA hydraulic valves, which can be divided into many types according to their functions and uses, such as pressure control valves, flow control valves, directional control valves, etc. Each type of valve has its specific application scenarios. By combining different types of hydraulic valves, complex hydraulic system control can be achieved.

The performance of hydraulic valves has a decisive impact on the performance of the entire hydraulic system. An excellent hydraulic valve should have the characteristics of precise adjustment, fast response, and high stability.

Hydraulic valves are very common in modern mechanical equipment. Especially in scenarios that require high-precision and high-efficiency control, such as aerospace, precision machine tools, high-end manufacturing and other fields, the role of hydraulic valves is obvious. For these fields, the performance of hydraulic valves is directly related to the operating accuracy and stability of the equipment. Research and development of high-performance hydraulic valves is an important part of promoting the development of science and technology.

The poocca manufacturer’s stock products include Vickers DG4V hydraulic valve, Yuken valve DFA DFB, P40 P80 P120 and more hydraulic valves waiting for your consultation.

There are four types of POOCCA hydraulic valves: pressure control valve, flow control valve, directional control valve and relief valve. Each type of valve has a specific function in a hydraulic system.

1. Pressure control valves control the pressure in a system by regulating the flow of fluid into the system or restricting the flow of fluid out of the system. They maintain a constant pressure level within the system by automatically regulating fluid flow.

2. Flow control valves control the rate of fluid flow through the system by limiting the flow of fluid through the valve. They maintain a constant flow rate by automatically adjusting the size of the valve opening to meet the demands of the fluid in the system.

3. Directional control valves control the direction of fluid flow in a system by directing the fluid flow to a specific port or channel. They are used to switch between different functions or operations in the system, such as extending or retracting a hydraulic cylinder.

4. Safety valves are used to protect the system from excessive pressure. If the pressure in the system exceeds a preset limit, the safety valve opens to release the fluid and reduce the pressure. They are designed to prevent damage to components in the system and maintain safe operating conditions.

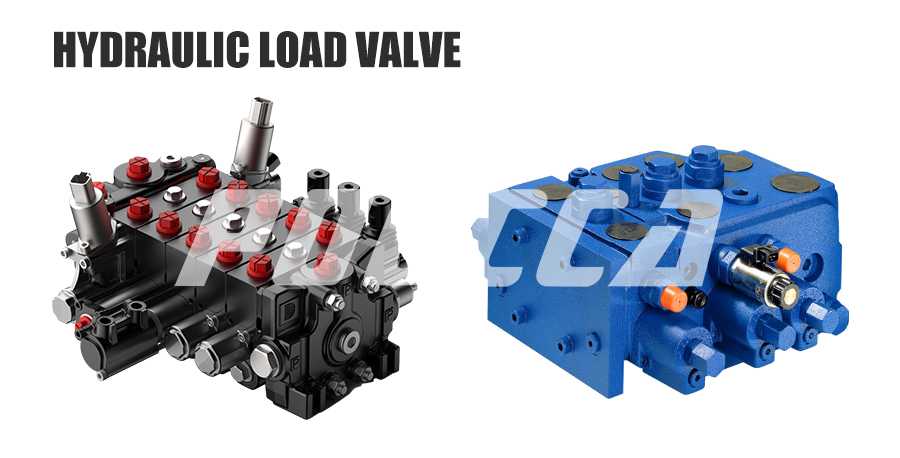

Hydraulic load valves are components in fluid power systems and they are used in a variety of industrial applications, including manufacturing, construction and mining, where machines and equipment require precise control of hydraulic actuation functions.

At its core, a hydraulic load valve is a control valve that manages the flow of hydraulic oil within the system. It is designed to maintain a constant pressure level in the hydraulic circuit, ensuring that the system can perform its designated tasks efficiently and safely. The valve senses the pressure within the circuit and regulates fluid flow accordingly, maintaining a stable pressure level.

It ensures that a hydraulic cylinder or motor receives the correct amount of fluid at the appropriate pressure to perform the desired movement or function. If there is a sudden increase in load, the valve regulates fluid flow to maintain pressure levels and prevent damage to system components.

POOCCA offers hydraulic load valves in a variety of designs and sizes to meet the fluid power system requirements of your desired product. Usually installed in the hydraulic line connecting the pump to the actuator to ensure that the correct amount of fluid is delivered to the equipment that needs to be driven.

At the heart of every hydraulic system is a network of valves, each designed to perform a specific function with extremely high precision. These valves regulate the flow of hydraulic oil, directing it to actuators, cylinders or other hydraulic components according to the requirements of the system.

One of the most common types of hydraulic valves is the directional control valve. As the name suggests, this valve determines the direction of fluid flow within the system. By selectively opening or closing specific channels, directional control valves enable machinery to move forward, backward, or to a neutral position, helping to precisely control movement and operation.

Another important type of hydraulic valve is the pressure control valve. This valve maintains optimal pressure levels within the hydraulic system, preventing damage to components due to excessive pressure. When the pressure exceeds a predetermined threshold, the pressure control valve opens, allowing fluid to bypass or return to the reservoir, effectively regulating pressure and ensuring system stability.

Flow control valves are also essential to control the rate at which fluid flows through the system. The flow control valve adjusts the speed of the actuator by adjusting the valve opening and skillfully controls the movement of the machine. This feature is especially important in applications where precise speed control is critical for safety and efficiency.

Proportional valves represent a major advance in hydraulic technology, providing infinitely variable control of flow, direction and pressure. These valves utilize electronic signals to regulate fluid flow, providing unparalleled precision and responsiveness in complex hydraulic systems. Proportional valves are revolutionizing industries such as aerospace, automotive and robotics, where precise control is critical.

The operation of hydraulic valves demonstrates the principles of fluid dynamics and control theory. Behind the scenes, complex mechanisms such as spool valves, poppet valves and solenoids precisely control fluid flow, responding in real time to signals from sensors and control systems. This seamless integration of mechanical and electronic components ensures that the hydraulic system operates reliably and efficiently in different environments.

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us via whatsapp

Welcome to contact us using WeChat