Menu

Close

Menu

Close

Poocca gear pumps include internal gear pumps and external gear pumps.

The gear pump has a simple structure, reliable operation, light weight and small size. Poocca’s gear pumps are the first and repeat purchase choice for most gear pump buyers. They are independently produced and sold at factory prices to ensure that you receive products with affordable prices and guaranteed quality.

For Rexroth Shimdazu Marzocchi Sunny Parker,Replacement hydraulic pumps and accessories from other brands.

Gear pump types include: AZPF, SGP, PGP, HGP, HG, NSH, AZPFF, etc. Send your requirements and we will get back to you as soon as possible.

Our manufacturing facility houses many CNC machines capable of producing high-quality hydraulic components and replacement parts.

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 1997 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts. With extensive experience in providing power transmission and drive solutions to hydraulic system users around the world, we have a strong reputation in the industry.

Over the past two decades, POOCCAHydraulics has continued to grow and innovate in the field of hydraulics. We have won the trust of domestic and foreign manufacturers and established strong corporate partnerships. Our annual export volume is up to US$16 million and exported to more than 100 countries. We have established long-term and stable cooperative relationships with dealers in more than 75 countries, including the United States, Indonesia, Mexico, Thailand, Russia and Brazil.

Gear pumps are positive displacement pumps that work by creating a chamber that transfers fluid through the meshing of gears within a housing. POOCCA has products of external gear pumps and internal gear pumps. This design allows for continuous and pulsation-free flow, distinguishing gear pumps from other types of pumps. Their simple construction, often consisting of only a few components, contributes to easy maintenance and cost-effective operation.

advantage:

Reliability: The gear pump’s simple design contributes to its reliability, making it suitable for a wide range of applications.

Versatility: Gear pumps can handle fluids of varying viscosities, demonstrating their versatility in different industrial processes.

Compact size: The gear pump has a compact size and can be easily integrated into systems with limited space, thereby enhancing its adaptability in different environments.

shortcoming:

Pulsation: One of the major disadvantages of gear pumps, especially external gear pumps, is the potential for fluid pulsation. This pulsating flow can be a problem in applications that require smooth, continuous fluid transfer.

Limited high-pressure applications: While gear pumps are efficient in many situations, they may not be ideal for high-pressure applications due to potential wear on the gear surfaces.

Accuracy Limitations: Gear pumps may have limitations in accuracy compared to more complex pump types, especially in metering applications where accurate metering is critical.

POOCCA external gear pumps include REXROTH AZPF, AZPG, AZPFF, SHIMADZU SGP, PARKER PGP, SALAMI 1.5PE, 2.PB, MARZOCCHI ALP, GHP, HYDROMAX HGP and other pumps

External gear pumps belong to a family of positive displacement pumps. The core of these pumps consists of two gears – a driving gear and a driven gear – rotating inside and outside the pump casing. This dynamic interaction of the gears creates a chamber capable of sucking in and discharging fluid, making external gear pumps a popular choice for a variety of applications.

Gears in action:

External gear pumps use two gears, a larger driving gear and a smaller driven gear. These gears mesh on the outside, creating a seal between the teeth.

The rotation of the gear creates a void or chamber that draws fluid into the pump during the suction phase.

Fluid motion:

As the gear continues to rotate, fluid is displaced and squeezed out through the discharge port, thus promoting continuous flow.

This simple design with fewer components helps improve the reliability and efficiency of external gear pumps.

Cross-industry applications:

Hydraulic system:

External gear pumps are widely used in hydraulic systems and contribute to the power steering mechanism of automobiles.

Their ability to handle varying pressures and provide consistent performance makes them an integral part of hydraulic applications.

Lubrication system:

The simplicity and reliability of external gear pumps make them ideal for mechanical lubrication systems, ensuring smooth operation and longevity of moving parts.

Industries ranging from manufacturing to agriculture rely on these pumps for efficient lubricant delivery.

Versatility is the hallmark of external gear pumps, making them suitable for a variety of fluid transfer applications.

POOCCA internal gear pump product oils include SUNNY HG, REXROTH PGH, ECKERLE EIP, ECKERLE PFG and other products.

Internal gear pumps are a special type of positive displacement pump. These pumps are composed of internal gears and external gears. They work on the principle that the gears inside the pump housing mesh to facilitate fluid transfer. Let’s take a closer look at the core features and applications of internal gear pumps:

The internal gear pump consists of an outer rotor with a larger number of teeth and an inner rotor with a smaller number of teeth. These gears mesh internally to form a sealed chamber for fluid transfer.

The meshing of the gears causes the chamber to expand and contract, drawing in fluid and then expelling it through the discharge port.

Fluid motion:

The precise interaction between the internal and external gears ensures consistent and controlled flow of fluid. This design minimizes fluid pulsation, making internal gear pumps ideal for applications requiring smooth, stable flow.

Metrology applications:

Internal gear pumps excel in applications where precision and accuracy are critical, such as dosing and batching in chemical processing.

Their ability to provide pulse-free flow makes them vital in situations where accurate measurement is critical.

High viscosity fluids:

Internal gear pumps are designed to handle high viscosity fluids efficiently. This capability makes them reliable performers in industries that handle materials of varying thicknesses.

Hydraulic system:

Internal gear pumps are used in hydraulic systems where consistent flow without pulsation is critical. This ensures the smooth operation of various hydraulic machinery.

Internal gear pumps are distinguished by their ability to significantly reduce fluid pulsation, providing smoother, more consistent flow compared to other pump types.

Known for its accuracy in metering applications, this hydraulic pump ensures precise dosing of fluids in chemical and pharmaceutical manufacturing processes.

The design complexity of internal gear pumps may increase manufacturing costs and maintenance compared to external gear pumps. As industries continue to seek greater efficiency and precision, internal gear pumps remain at the forefront of innovation. Ongoing research and development aims to further optimize its design, potentially extending its applications and solidifying its role in shaping the future of fluid transfer technology.

Durable hydraulic pumps also need maintenance. Poocc has many years of hydraulic experience and has compiled the maintenance points of hydraulic gear pumps for everyone:

POOCCA gear pumps are hydraulic transmission devices that can be used in many industrial fields. It generates pressure through the rotation of gears and transports liquid from low-pressure areas to high-pressure areas.

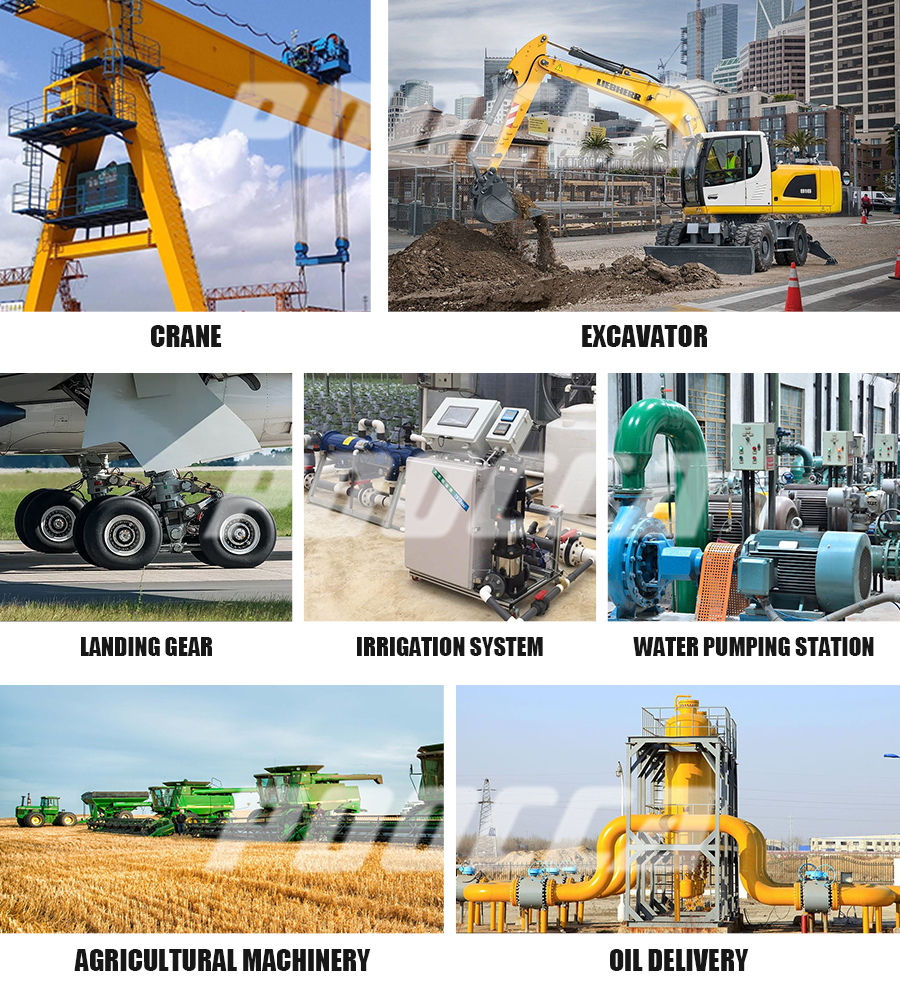

It can provide stable hydraulic power for driving actuators such as hydraulic cylinders and hydraulic motors. In engineering machinery, aerospace, metallurgy and other industries, gear pumps are widely used in hydraulic systems of cranes, excavators, aircraft landing gear and other equipment.

Also commonly used in the petrochemical industry. It can be used to transport various liquids, such as petroleum, chemical raw materials and finished products. In refineries, chemical plants and other places, gear pumps are used to transport crude oil, fuel oil, lubricating oil and other liquids, as well as transport chemicals, solvents, etc.

Gear pumps are also used in agriculture and water conservancy projects. In agricultural machinery, gear pumps can be used in irrigation systems, sprayers and other equipment to control and regulate water. In water conservancy projects, gear pumps can be used in water pumping stations, water pumping stations and other equipment to lift and drain water.

As a common hydraulic transmission device, gear pumps have a wide range of applications and provide reliable hydraulic power and liquid delivery solutions for various industries.

If you are looking for hydraulic products for your application equipment, please do not hesitate to send us your requirements immediately and let POOCCA’s professionals assist you in finding the right product for you.

POOCCA has decades of experience in the field of hydraulics. We have cooperated with customers in many countries many times. In this process, we will inevitably encounter other problems with the gear pump. The gear pump is not working properly. One thing you need to rest assured is that the products POOCCA sends to you are all brand new and each unit is packed and shipped after passing testing. Therefore, the on-site environmental reasons should be checked as soon as possible at this time. We’ll organize them below. If you have any questions about the 12 o’clock inspection, please feel free to contact us.

Eye exam:

Leakage and Seals: Start by visually inspecting the pump for any signs of leakage around seals, fittings or connections. Prompt resolution of leaks is critical to preventing fluid loss and contamination.

External Condition: Assess the overall condition of the pump, looking for any damage, corrosion, or abnormal wear. External irregularities may indicate underlying problems.

Check fluid level:

Make sure the pump has a sufficient supply of the appropriate fluid. Low fluid levels can cause cavitation, reduce pump efficiency and lead to premature wear.

Monitor operating temperature:

Measure the operating temperature of the pump. Overheating may indicate problems such as overloading, insufficient lubrication, or inefficient fluid flow. The root cause must be addressed promptly to prevent damage.

Listen for any unusual sounds:

Pay attention to the sounds the pump makes during operation. Unusual noises, such as grinding, knocking, or excessive vibration, may indicate problems with gears, bearings, or misalignment. Investigate and resolve these issues promptly.

Check inlet and outlet pressure:

Use appropriate pressure gauges to measure pump inlet and outlet pressure. Deviations from recommended pressure levels may indicate problems with the pump, valve, or entire system.

Check installation and alignment:

Make sure the pump is securely mounted and properly aligned. Misalignment can cause increased gear and bearing wear, affecting overall performance. Correct any misalignment issues to maintain optimal pump operation.

Check the number of gear teeth:

Carefully inspect the gear teeth for signs of wear, chipping, or damage. Worn gear teeth can reduce efficiency and cause pump failure. If necessary, replace the gear promptly to prevent further damage.

Analyze oil condition:

Check the condition of the pump lubricant. Contaminated or spoiled oil can affect pump performance. Change your engine oil regularly and use the recommended type to ensure proper lubrication.

Monitor pump speed:

Measure the pump’s RPM and compare it to the manufacturer’s specifications. Speed deviations may indicate a problem with the drive system, motor, or transmission.

Utilize condition monitoring systems to:

Implement advanced condition monitoring systems, including sensors and alarms, to continuously assess pump health. These systems can provide real-time data to identify potential problems early.

Perform performance testing:

Perform regular performance tests to evaluate pump efficiency and output. Compare the results to the pump’s original specifications to determine if there is any degradation in performance.

Regular maintenance:

Develop a routine maintenance schedule that includes tasks such as lubrication, seal replacement, and gear inspections. Regular maintenance helps prevent unexpected failures and extends the life of your pump.

During your communication process, POOCCA will use these parameters to confirm whether the hydraulic gear pump you need is correct. While this is a very basic verification operation, one of our Brazilian customers reported to us that he had had it provided elsewhere before. Shangshi customized a batch of more than 1,000 gear pumps, but because the parameters were not fully adjusted, the pump pressure they received did not reach the pressure they required, and thus they could not operate normally. While the water pump could not be fully refunded, it also had to pay expensive logistics fees, causing serious losses to them. Later he found POOCCA and our cooperation went smoothly. This year is already the second year of our cooperation.

pooccca will never allow such low-level errors. We will protect the interests of our customers.

Therefore, please rest assured POOCCA, we are a professional one-stop hydraulic purchasing company.

The main function of the hydraulic gear pump is to convert mechanical energy into liquid pressure energy. The basic parameters of a hydraulic gear pump are important for understanding its performance, selecting the appropriate pump type, and correct use and maintenance. Some of the main basic parameters are:

Displacement: For each revolution of the hydraulic gear pump, the liquid volume produced by the change in seal volume is called displacement. Displacement is one of the important performance parameters of a hydraulic gear pump, usually expressed in milliliters/revolution (mL/r) or cubic centimeters/revolution (cm³/r).

Flow: The volume of liquid discharged by a hydraulic gear pump per unit time is called flow. Flow rate is related to the speed and displacement of the pump, and is usually expressed in liters per minute (L/min) or cubic meters per hour (m3/h).

Pressure: The liquid pressure output by the hydraulic gear pump is called working pressure. Working pressure is related to factors such as pump displacement, flow rate, input power, and system resistance. Working pressure is usually expressed in MPa or bar.

Efficiency: The ratio of the actual output flow of the hydraulic gear pump to the theoretical output flow is called efficiency. Efficiency is an important parameter to measure the energy loss of a hydraulic gear pump, usually expressed as a percentage.

Speed: The speed of the hydraulic gear pump is called the speed. The rotational speed directly affects the flow and pressure of the pump and is usually expressed in revolutions per minute (r/min).

Driving mode: The hydraulic gear pump has two driving modes: direct drive and indirect drive. Direct drive means that the pump is directly driven by the motor, and indirect drive means that the pump is connected to the motor through transmission devices such as couplings and pulleys.

Temperature: When the hydraulic gear pump is working, heat will be generated due to friction, compression and other energy losses, which will increase the temperature of the pump. Temperature is an important factor affecting the performance and life of hydraulic gear pumps, and is usually expressed in degrees Celsius (℃).

Noise: During the working process of the hydraulic gear pump, the sound generated due to liquid flow, gear meshing, etc. is called noise. Noise can affect the working environment and the health of operators, and is usually expressed in decibels (dB).

Service life: The time a hydraulic gear pump can maintain specified performance and functions under normal working conditions is called service life. The service life is related to factors such as the material, manufacturing process, use and maintenance of the pump.

Installation method: The installation methods of hydraulic gear pump include horizontal installation, vertical installation and inclined installation. Different installation methods are suitable for different working conditions and usage environments.

The basic parameters of a hydraulic gear pump cover its performance, working principle, use and maintenance, etc., which is of great significance for the correct selection and use of a hydraulic gear pump. In actual projects, it is necessary to select a suitable hydraulic gear pump based on specific working conditions and usage requirements, comprehensively considering various parameters. Then the hydraulic gear pump also needs regular inspection, maintenance and upkeep to ensure its normal operation and extend its service life.

POOCCA Hydraulics Manufacturer’s technical drawings generally present object information in the form of two-dimensional views, although in some cases three-dimensional views are also provided. Producing technical drawings can be done manually or with computer assistance. Typically, these drawings are prepared or printed on standard size paper.

In addition, complete mechanical drawings express the structure, dimensions, materials, accuracy, etc. of a part or component or a machine and all design data used in the mechanical industry. For mechanical dimensions (such as the diameter of a cylinder), whether tolerances are marked or not, they represent a range, called mechanical (dimensional) accuracy. This is because mechanical parts are generally produced in large quantities, and precision is required to control the size of each part within a certain range. POOCCA Hydraulics can provide you with relevant drawings of the products you need. Please send your request and we will reply to you as soon as possible.

At the same time, POOCCA has a variety of gear pumps for sale, including single gear pumps, double gear pumps, triple gear pumps, etc.

Gear pumps are essential components in a variety of industrial applications, helping to move fluids accurately and efficiently. However, like any mechanical system, gear pumps can experience failures that interrupt operations and lead to costly downtime. Recognizing the causes of gear pump failure is important to implement preventive measures and ensure the longevity of this important equipment

1. Pollution:

Cause: One of the main causes of gear pump failure is contamination of the pumped fluid. Contaminants such as dirt, debris or particles can damage gears, bearings and other critical components.

Solution: Implement an effective filtration system to remove contaminants from the fluid. Check and replace the filter regularly to ensure the cleanliness of the fluid entering the pump.

2. Cavitation:

Reason: Cavitation occurs when a fluid’s pressure falls below its vapor pressure, causing the formation and collapse of vapor bubbles. This process can corrode pump components and cause damage.

Solution: Maintain proper fluid levels, check for leaks, and ensure adequate suction conditions to prevent cavitation. If necessary, adjust pump speed or use a larger pump to mitigate the risk of cavitation.

3. Overload:

Reason: Overloading can occur when a gear pump is operated beyond its design capacity. This can lead to increased stress on gears, bearings and drive systems, leading to premature failure.

Solution: Make sure the pump is sized appropriately for the application. Monitor operating conditions and take measures such as pressure relief valves to prevent overloading.

4. Poor lubrication:

Reason: Insufficient lubrication causes increased friction, heat and wear on gear pump components. Insufficient lubrication can be caused by low oil levels, poor quality lubricant or irregular maintenance.

Solution: Maintain proper lubrication levels and use recommended lubricants. Establish a daily lubrication plan, check and replace lubricants regularly to prevent wear and tear.

5. Dislocation:

Reason: Misalignment of the gear pump with the drive system or other connected components can lead to increased wear, increased vibration and reduced efficiency.

Solution: Check regularly and correct any misalignment issues. Make sure the pump is securely mounted and aligned with the motor or other drive mechanism.

6. Wear:

Cause: Over time, normal wear and tear causes gear teeth, bearings, and seals to degrade. Continuous operation without proper maintenance will accelerate this natural aging process.

Solution: Implement a routine maintenance program that includes inspection of gear teeth, bearings and seals. Replace worn parts promptly to prevent further damage.

7.Extreme temperatures:

Reason: Operating a gear pump at extreme temperatures (too high or too low) can affect the viscosity of the fluid, affect lubrication properties, and cause thermal expansion or contraction of components.

Solution: Monitor and control pump operating temperature. Implement measures such as cooling systems or insulation to maintain optimal temperature conditions.

Regular maintenance, correct selection, monitoring operating conditions and timely problem solving are key strategies to improve the reliability and service life of gear pumps. By taking a proactive approach to maintenance and troubleshooting, industries can minimize downtime, reduce repair costs and optimize gear pump system performance.

POOCCA’s new gear pumps are designed and manufactured to reduce maintenance requirements and costs, making maintenance of hydraulic equipment simpler and easier. The gear pump is a key component in the hydraulic system, responsible for converting mechanical energy into liquid pressure energy. However, due to the complexity of its internal parts, traditional gear pumps require regular fine adjustments and component replacement, which undoubtedly increases the complexity and time cost of maintenance work.

The new generation of gear pumps adopt innovative designs and materials, which significantly reduce maintenance difficulty while maintaining efficient performance. According to industry experts, these new design features include greater bearing capacity, higher gear accuracy and greater resistance to wear.

The larger bearing capacity allows the gear pump to withstand greater pressure and shock during continuous operation, reducing downtime and repair costs due to excessive wear. This also means fewer bearing replacements, resulting in lower maintenance costs.

The new gear pump’s gears are more precise, reducing internal leakage and energy loss, and improving overall efficiency. This not only helps save energy but also reduces the need for hydraulic oil, further reducing operating costs and maintenance requirements.

The anti-wear materials and advanced surface treatment technology used in the new gear pump greatly extend its service life. This means users can avoid costly repairs or replacement parts for longer.

In addition to these design improvements, the new gear pumps are equipped with a more advanced monitoring system that monitors pump performance and status in real time. This allows us to detect and fix problems before they become serious, further reducing repair time and expense.

The gear pump is a common power transmission equipment, and its performance directly affects the operating efficiency and stability of the entire system. The noise problem generated by traditional gear pumps during operation has always been the focus of attention in the industry. POOCCA’s hydraulic gear oil pumps are used. Many customers have reported that there is almost no noise and the operation is very smooth. In fact, during the operation of traditional gear pumps, due to the influence of factors such as gear meshing and bearing operation, there will be Produce some noise. This not only affects the working environment of the operators, but also causes noise pollution to the surrounding environment. However, our POOCCA hydraulic pumps, in addition to gear pumps, piston pumps, vane pumps, motors and other products have very low noise. POOCCA hydraulic pumps adopt advanced noise control technology and effectively reduce noise by optimizing gear design and material selection. Reduce the noise generated by the gear pump during operation. According to tests, the noise value of this product is 20% lower than similar products.

Gear pumps also have the advantages of high efficiency, high pressure, and long life. The special tooth profile design makes the gear meshing smoother, reduces friction loss, and improves work efficiency. At the same time, its high-strength shell design and high-quality sealing materials enable the gear pump to operate stably under high-pressure conditions, greatly extending the service life of the product.

POOCCA’s gear pumps have passed a number of domestic and foreign authoritative certifications and have been widely recognized in the market. In the future, POOCCA will continue to increase investment in research and development and launch more innovative hydraulic products to meet the changing market needs.

The issue of gear pump wear has become a focus in the hydraulic industry, prompting us POOCCA engineers and researchers to gain a deeper understanding and mitigate this inevitable process.

Before we delve into wear, we need to understand the basic functions of a gear pump. These devices consist of interlocking gears that produce a continuous flow of hydraulic oil. Fluid is pressurized and directed to various components within the hydraulic system, allowing the machine to perform its intended task.

Causes of wear:

Gear pumps, like any mechanical component, are susceptible to wear over time. Several factors can contribute to gear pump wear, and understanding these mechanisms is critical to developing an effective maintenance strategy.

The constant motion of the gears against each other and the pump casing causes friction and wear. Over time, this causes the surface to gradually wear away, affecting the overall efficiency of the pump.

Hydraulic systems are not immune to contamination, and particles such as dirt, debris, and metal shavings can find their way into the gear pump. These contaminants act as abrasives, accelerate wear and impair pump performance.

Extreme temperatures, whether too high or too low, can affect the viscosity of hydraulic fluids. This in turn affects the lubrication properties of the fluid, making the gears more susceptible to wear.

Methods to extend the service life of gear pumps:

Efforts to extend the service life of gear pumps revolve around proactive maintenance and addressing the root causes of wear. After purchasing a product from POOCCA Hydraulics, we have a 12-month guarantee. If there is a problem with the product during installation or operation, our professional technical staff will provide 24-hour online technical support to protect you during use.

Regular Fluid Analysis: Implementing routine fluid analysis procedures provides early detection of contaminants and degradation in hydraulic fluids. Prompt fluid changes and filtration can help prevent accelerated gear pump wear.

Optimize lubrication: Maintaining proper lubrication is critical to reducing friction between gears. Lubricants containing high viscosity and anti-wear additives help minimize wear and extend the life of the gear pump.

Temperature Control: Monitoring and controlling the temperature of hydraulic systems can help prevent fluid viscosity problems. This ensures that the fluid’s lubrication properties remain optimal and reduces wear on gear pump components.

Material improvements: Ongoing research is focused on developing wear-resistant materials for gear pump components. Advances in materials engineering aim to create gears and housings that can withstand long-term use and minimize wear.

While acknowledging the inevitability of wear and tear, POOCCA hydraulics professionals are actively involved in developing and implementing strategies to mitigate its effects. Through a combination of advanced materials, proactive maintenance and smart solutions, the hydraulics industry aims to achieve a balance between optimal performance and extended gear pump service life.

Gear pumps have long been considered reliable workhorses, dutifully transferring fluids in one direction. However, recent advances in engineering challenge this conventional wisdom and push the limits of what gear pumps can achieve. Enter the age of the reversible gear pump, a game-changing innovation that promises to revolutionize industries.

Traditionally, gear pumps work on a simple principle: two intermeshing gears rotate inside a housing, capturing fluid and transferring it from the inlet to the outlet. This unidirectional flow has served countless applications, from hydraulic systems in heavy machinery to fuel transfer in automotive engineering. However, this one-way functionality creates limitations in scenarios where bidirectional fluid movement is required.

The advent of reversible gear pumps marked a major leap forward in fluid handling technology. Engineers cleverly redesigned the internal mechanisms of gear pumps to enable bi-directional flow, effectively unlocking countless new possibilities across industries. The impact is profound, providing enhanced versatility and efficiency in a variety of applications.

One of the main driving forces for the development of reversible gear pumps is the growing demand for energy-saving systems. By allowing fluids to be pumped in both directions, these pumps enable innovative solutions such as regenerative braking in hybrid vehicles and energy recovery in industrial processes. This newfound capability not only saves energy but also reduces environmental impact, in line with the global push for sustainability.

The versatility of reversible gear pumps extends to applications requiring precise control of fluid flow. In industries such as pharmaceuticals and food processing, where product quality and safety are subject to strict regulations, the ability to precisely manipulate the direction of fluids is invaluable. Reversible gear pumps provide unparalleled control, facilitating precise metering, mixing and dispensing operations with the highest precision.

POOCCA hydraulic manufacturer was established in 1997 and has 26 years of experience in the hydraulic industry.

We have up to 1,600 product categories, mainly engaged in gear pumps, piston pumps, vane pumps, motors, hydraulic accessories, hydraulic valves, etc.

Our product order delivery times may vary based on the specific product and its availability.

Regular products take 5-7 days, special products depend on customization time and quantity.

12 months

Our factories are located in Guangdong, Jiangsu and Zhejiang. The annual export volume is as high as 16 million US dollars.

We accept a variety of payment methods including credit card, bank transfer, PayPal, and more.

For large orders, 30% can be paid in advance and the remaining 70% is paid before shipment.

Yes, we offer expedited international shipping options for your convenience. Please contact our sales team to discuss your specific requirements.

Our products adhere to industry standards and often hold certifications such as [Certification Name]. We are committed to maintaining the highest quality and safety standards.

Yes, we offer product samples and demos to help you choose. Please contact our sales team to arrange.

Yes, we have extensive references and case studies to prove the successful implementation of the product. Please contact our sales team for these resources.

If there is a problem with the quality of the product, it can be returned or exchanged if it complies with the return and exchange policy.

Our products undergo strict quality control and testing procedures. We also have a dedicated quality assurance team to maintain the highest standards. In addition, we regularly invest in research and development to improve our products and stay at the forefront of the industry.

Yes, we offer volume discounts and can provide customized solutions for bulk orders. Please contact our sales team to discuss your specific requirements and pricing options.

You can track your order using the tracking number provided after your order is shipped. Our shipping partners offer tracking services so you can track the progress of your shipment online.

Yes, we provide online installation instructions, maintenance instructions, and technical support resources for our products. Our customer service and technical teams are here to help.

We prioritize sustainability and environmentally responsible manufacturing. Our products are designed with the environment in mind, and we actively participate in sustainability initiatives.

We welcome tours of our facilities and headquarters. Please contact us to arrange a visit and we will be happy to provide insight into our operations and quality control measures.

Consider factors such as flow, pressure and system requirements. Of course, we will also assist you in selection and find the product that suits you.

Hydraulic hoses and fittings are used to carry hydraulic fluid between components in a hydraulic system.

Hydraulic oil transmits power, lubricates components and dissipates heat within the system.

Change and filter hydraulic oil regularly, keep the system clean, and use high-quality filters.

Filtration removes contaminants to maintain system performance and extend component life.

Regular maintenance ensures system reliability, efficiency and minimizes downtime.

Check for leaks, monitor pressure and temperature, and inspect components for wear or damage.

The accumulator stores hydraulic energy, suppresses pressure fluctuations, and can provide emergency power.

Hydraulic valves control fluid flow, pressure, and direction to manage system functions.

Proportional valves provide precise control of flow or pressure, while directional valves manage fluid direction.

Consider factors such as flow, pressure and control requirements to make the best choice.

Hydraulic cylinders are linear actuators used in applications such as construction equipment and manufacturing.

The cylinder extends and retracts when hydraulic oil pressurizes or depressurizes the sides of the piston.

Options include JIC, NPT, SAE and metric fittings for connecting hoses and components.

Regular inspections, proper training and safety protocols are vital to maintaining safety.

Flushing before system assembly or during maintenance removes contaminants and prevents damage.

Proper lubrication, maintenance and compliance with recommended operating parameters are critical.

Seals prevent fluid leakage and maintain pressure within components.

Viscosity affects the fluid's ability to flow and lubricate; it is chosen based on system requirements.

Quick couplers provide a quick, secure connection between hydraulic lines and components.

Consider load, speed, and pressure requirements to select an appropriately sized hydraulic motor.

Hydraulic systems provide high power-to-weight ratio, precise control, and the ability to transmit power over long distances.

Pressure relief valves protect the system from overpressure by releasing excess fluid.

Regular maintenance, monitoring for signs of wear, and following manufacturer's operating and maintenance guidelines can extend the life of components and systems.

Factors to consider include material compatibility, temperature range and specific application requirements.

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us via whatsapp

Welcome to contact us using WeChat