Menu

Close

Menu

Close

GENERAL CHARACTERISTICS:

Maximum pressures up to 300 bar

Weight : from 0.9 Kg to 1.6 kg

Maximum speed up to 5.000 rpm

Type of shafts:Taper 1:8

Oldham

Slined DIN 5482

SAE AA

Keyed

Type of flanges:

European standard

Standard for power units

SAE AA standard

Displacements from 0.73 cc/rev to 9.9 cc/rev

A special version with built-in bracket and a larger taper 1:8 shaft (diameter 014) for pumps with 9.9 ml/rev.

In this series there are double-chamber pumps with rear cover relief valve and pumps with built-in maximum pressure relief valve (with internal or external drain)

driver:

It is best to use a flexible coupling to connect the pump to the motor to avoid any radial and/or axial forces on the shaft, otherwise the efficiency of the pump will drop sharply due to early wear of the internal moving parts.

In any application where motion is transmitted by a belt, it is necessary to use brackets to protect the pump shaft from any radial or axial loads.

In any application where splined shafts or Oldham couplings are used it is recommended to ensure supplementary lubrication by means of grease or similar product.

| Type | DispIacement

( cc/rev ) |

Max

working pressure P1 ( bar ) |

Peak

pressure P3 ( bar ) |

Max

speed ( r.p.m) |

Dimension A B | Absorbed

torque at 15O bar ( Nm ) |

code

( Anti-cIockwise ) |

code

( cIockwise ) |

|

| ( mm ) | |||||||||

| OT 1OO PO7 | 0.73 | 200 | 240 | 5000 | 31.30 | 64.5 | 1.8 | PS1007081S | PS1007081D |

| OT 1OO P11 | 1.05 | 250 | 290 | 5000 | 31.90 | 65.6 | 2.4 | PS1007082S | PS1007082D |

| OT 1OO P16 | 1.45 | 260 | 300 | 5000 | 32.75 | 67.3 | 4.2 | PS1007083S | PS1007083D |

| OT 1OO P2O | 1.80 | 260 | 300 | 5000 | 33.45 | 68.7 | 5.2 | PS1007084S | PS1007084D |

| OT 1OO P25 | 2.45 | 260 | 300 | 5000 | 34.50 | 70.8 | 6.7 | PS1007085S | PS1007085D |

| OT 1OO P32 | 3.05 | 260 | 300 | 5000 | 35.50 | 72.8 | 8.3 | PS1007086S | PS1007086D |

| OT 1OO P4O | 3.80 | 260 | 300 | 4500 | 36.90 | 75.6 | 10.1 | PS1007087S | PS1007087D |

| OT 1OO P49 | 4.70 | 240 | 280 | 4500 | 38.45 | 78.7 | 12.7 | PS1007088S | PS1007088D |

| OT 1OO P58 | 5.55 | 200 | 240 | 4000 | 40.00 | 81.8 | 15.0 | PS1007089S | PS1007089D |

| OT 1OO P65 | 6.25 | 190 | 230 | 3750 | 41.25 | 84.3 | 16.8 | PS1007090S | PS1007090D |

| OT 1OO P79 | 7.60 | 170 | 220 | 3500 | 43.60 | 89.0 | 20.5 | PS1017091S | PS1017091D |

Hydraulic Systems: Gear pumps are widely used in hydraulic systems to generate flow and pressure for a variety of tasks, such as lifting heavy machinery, operating hydraulic presses, and controlling industrial equipment.

Oil and Gas Industry: Gear pumps are used in the oil and gas industry to transport crude oil, fuel and other petroleum products in refineries, pipelines and storage facilities.

Chemical Processing: These pumps are used in chemical processing plants to handle a variety of chemicals and corrosive liquids, performing tasks such as metering, mixing and transferring fluids.

Food and Beverage Industry: Due to their ability to handle viscous fluids, gear pumps are used to pump food products such as syrups, sauces and chocolate in food processing and packaging operations.

Agriculture: Gear pumps are used in agricultural machinery for tasks such as spraying pesticides, fertilizers and transporting agricultural chemicals.

Construction Equipment: They are used in construction machinery for applications such as concrete pumping, hydraulic power systems and lubrication.

Mining Operations: Gear pumps play an important role in mining operations, completing tasks such as dewatering, slurry transportation and heavy machinery lubrication.

GENERAL CHARACTERISTICS:

Maximum pressures up to 300 bar

Weight : from 0.9 Kg to 1.6 kg

Maximum speed up to 5.000 rpm

Type of shafts:Taper 1:8

Oldham

Slined DIN 5482

SAE AA

Keyed

Type of flanges:

European standard

Standard for power units

SAE AA standard

Displacements from 0.73 cc/rev to 9.9 cc/rev

A special version with built-in bracket and a larger taper 1:8 shaft (diameter 014) for pumps with 9.9 ml/rev.

In this series there are double-chamber pumps with rear cover relief valve and pumps with built-in maximum pressure relief valve (with internal or external drain)

driver:

It is best to use a flexible coupling to connect the pump to the motor to avoid any radial and/or axial forces on the shaft, otherwise the efficiency of the pump will drop sharply due to early wear of the internal moving parts.

In any application where motion is transmitted by a belt, it is necessary to use brackets to protect the pump shaft from any radial or axial loads.

In any application where splined shafts or Oldham couplings are used it is recommended to ensure supplementary lubrication by means of grease or similar product.

| Type | DispIacement

( cc/rev ) |

Max

working pressure P1 ( bar ) |

Peak

pressure P3 ( bar ) |

Max

speed ( r.p.m) |

Dimension A B | Absorbed

torque at 15O bar ( Nm ) |

code

( Anti-cIockwise ) |

code

( cIockwise ) |

|

| ( mm ) | |||||||||

| OT 1OO PO7 | 0.73 | 200 | 240 | 5000 | 31.30 | 64.5 | 1.8 | PS1007081S | PS1007081D |

| OT 1OO P11 | 1.05 | 250 | 290 | 5000 | 31.90 | 65.6 | 2.4 | PS1007082S | PS1007082D |

| OT 1OO P16 | 1.45 | 260 | 300 | 5000 | 32.75 | 67.3 | 4.2 | PS1007083S | PS1007083D |

| OT 1OO P2O | 1.80 | 260 | 300 | 5000 | 33.45 | 68.7 | 5.2 | PS1007084S | PS1007084D |

| OT 1OO P25 | 2.45 | 260 | 300 | 5000 | 34.50 | 70.8 | 6.7 | PS1007085S | PS1007085D |

| OT 1OO P32 | 3.05 | 260 | 300 | 5000 | 35.50 | 72.8 | 8.3 | PS1007086S | PS1007086D |

| OT 1OO P4O | 3.80 | 260 | 300 | 4500 | 36.90 | 75.6 | 10.1 | PS1007087S | PS1007087D |

| OT 1OO P49 | 4.70 | 240 | 280 | 4500 | 38.45 | 78.7 | 12.7 | PS1007088S | PS1007088D |

| OT 1OO P58 | 5.55 | 200 | 240 | 4000 | 40.00 | 81.8 | 15.0 | PS1007089S | PS1007089D |

| OT 1OO P65 | 6.25 | 190 | 230 | 3750 | 41.25 | 84.3 | 16.8 | PS1007090S | PS1007090D |

| OT 1OO P79 | 7.60 | 170 | 220 | 3500 | 43.60 | 89.0 | 20.5 | PS1017091S | PS1017091D |

Hydraulic Systems: Gear pumps are widely used in hydraulic systems to generate flow and pressure for a variety of tasks, such as lifting heavy machinery, operating hydraulic presses, and controlling industrial equipment.

Oil and Gas Industry: Gear pumps are used in the oil and gas industry to transport crude oil, fuel and other petroleum products in refineries, pipelines and storage facilities.

Chemical Processing: These pumps are used in chemical processing plants to handle a variety of chemicals and corrosive liquids, performing tasks such as metering, mixing and transferring fluids.

Food and Beverage Industry: Due to their ability to handle viscous fluids, gear pumps are used to pump food products such as syrups, sauces and chocolate in food processing and packaging operations.

Agriculture: Gear pumps are used in agricultural machinery for tasks such as spraying pesticides, fertilizers and transporting agricultural chemicals.

Construction Equipment: They are used in construction machinery for applications such as concrete pumping, hydraulic power systems and lubrication.

Mining Operations: Gear pumps play an important role in mining operations, completing tasks such as dewatering, slurry transportation and heavy machinery lubrication.

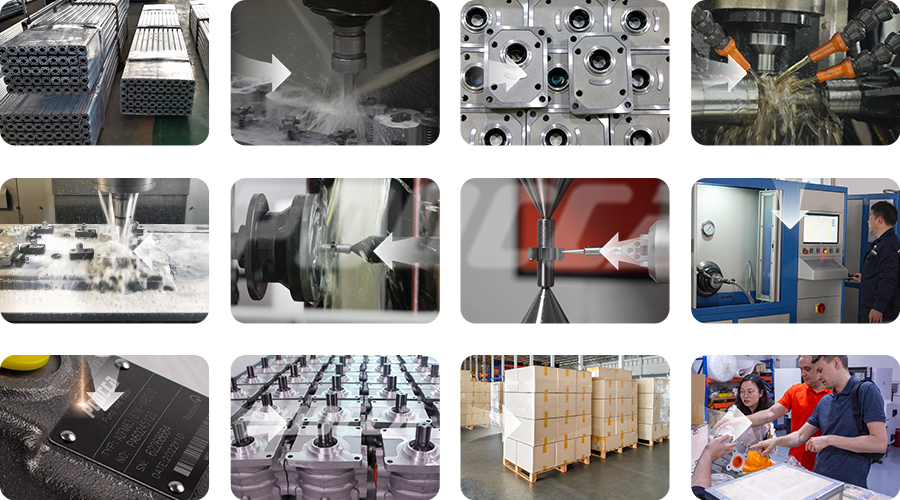

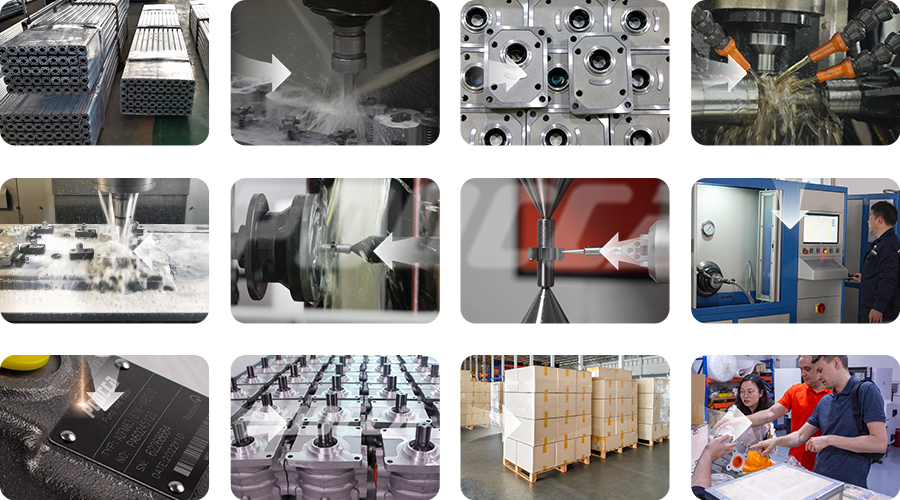

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us using WeChat

Welcome to contact us via whatsapp