Menu

Close

Menu

Close

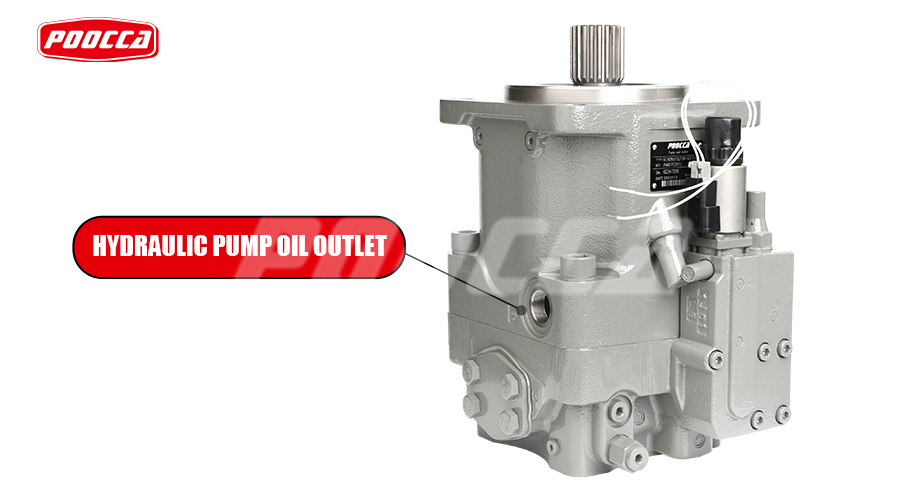

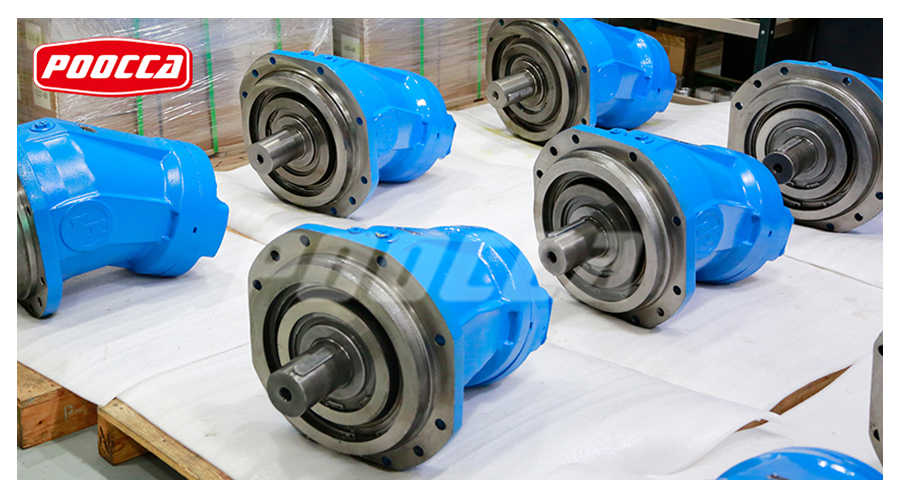

The piston pump product is POOCCA’s long-term best-selling product. The mating surface of the plunger and piston hole of the plunger pump is a cylindrical surface, which requires processing to obtain a high matching accuracy. All our products have been tested many times. POOCCA products can only leave the factory after passing the test. POOCCA products will almost never have quality problems such as cracking of the pump body.

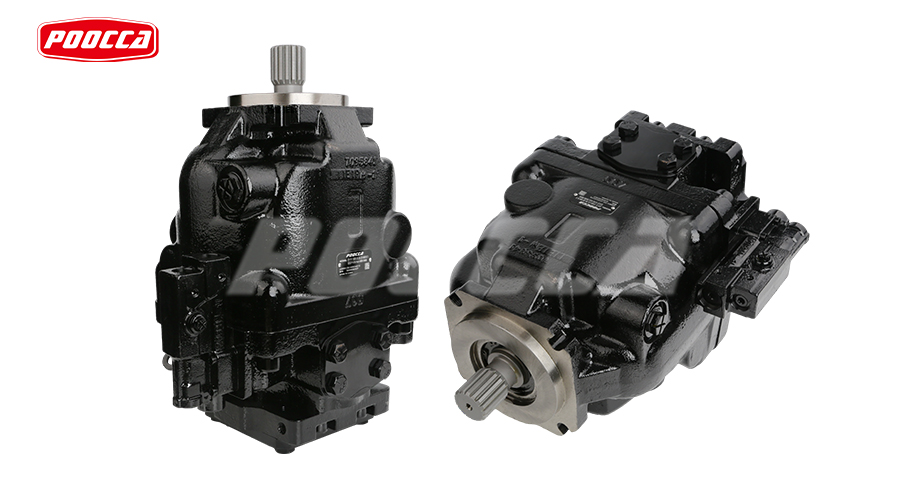

We provide a variety of displacements, mounting flanges, etc. to help you successfully purchase suitable hydraulic products. Among them, Rexroth Parker Denison Nachi Yunken is the most popular brand, and products such as A10VSO, PV, A2F, A4VSO, and PVQ have become the choices of many customers.

POOCCA has more than 20 years of experience, and can also meet your special requirements in terms of customization, providing you with customized services for products, logos, and brands.

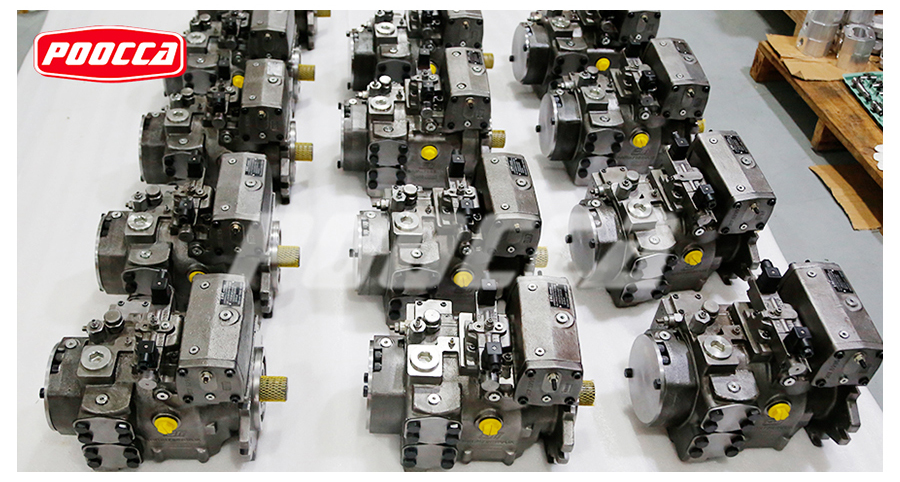

Our manufacturing facility houses many CNC machines capable of producing high-quality hydraulic components and replacement parts.

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 2006 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts. With extensive experience in providing power transmission and drive solutions to hydraulic system users around the world, we have a strong reputation in the industry.

Over the past two decades, POOCCAHydraulics has continued to grow and innovate in the field of hydraulics. We have won the trust of domestic and foreign manufacturers and established strong corporate partnerships. Our annual export volume is up to US$16 million and exported to more than 100 countries. We have established long-term and stable cooperative relationships with dealers in more than 75 countries, including the United States, Indonesia, Mexico, Thailand, Russia and Brazil.

Hydraulic piston pumps are at the heart of countless hydraulic systems and are the basic components that convert mechanical power into hydraulic energy. Understanding the inner workings of equipment can reveal the complexity of the pistons, fluids, and pressures that drive various mechanical and equipment functions.

Understand the basics of piston pumps and their importance

**Understand the structure of piston pump

**POOCCA piston pump series introduction

**Advantages and disadvantages of using piston pumps in different industries

**POOCCA hydraulic manufacturer customer feedback

**piston pump applications in vertical industries: from oil and gas to manufacturing

**Based on your specific needs, POOCCA assists in selecting the right hydraulic solution for you

1.Understand the basic knowledge and importance of pistonpumps

In the dynamic realm of hydraulic systems, piston pumps are indispensable components and play a key role in converting mechanical power into hydraulic energy. These pumps operate based on the reciprocating motion of a piston within a cylinder, producing a high-pressure fluid flow.

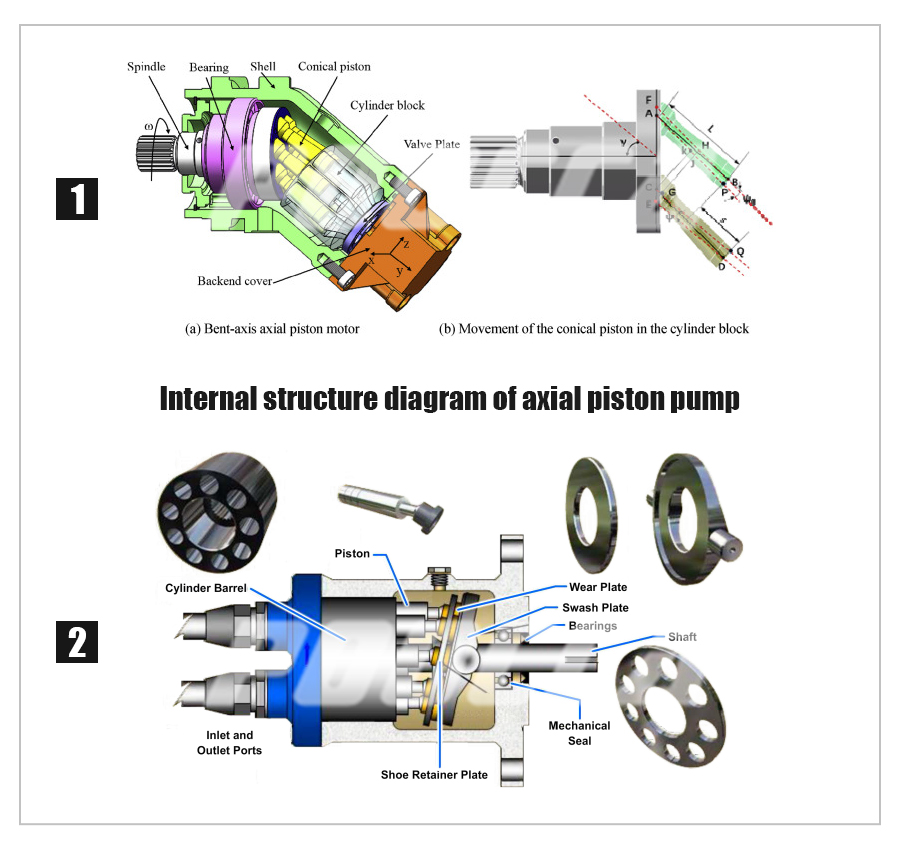

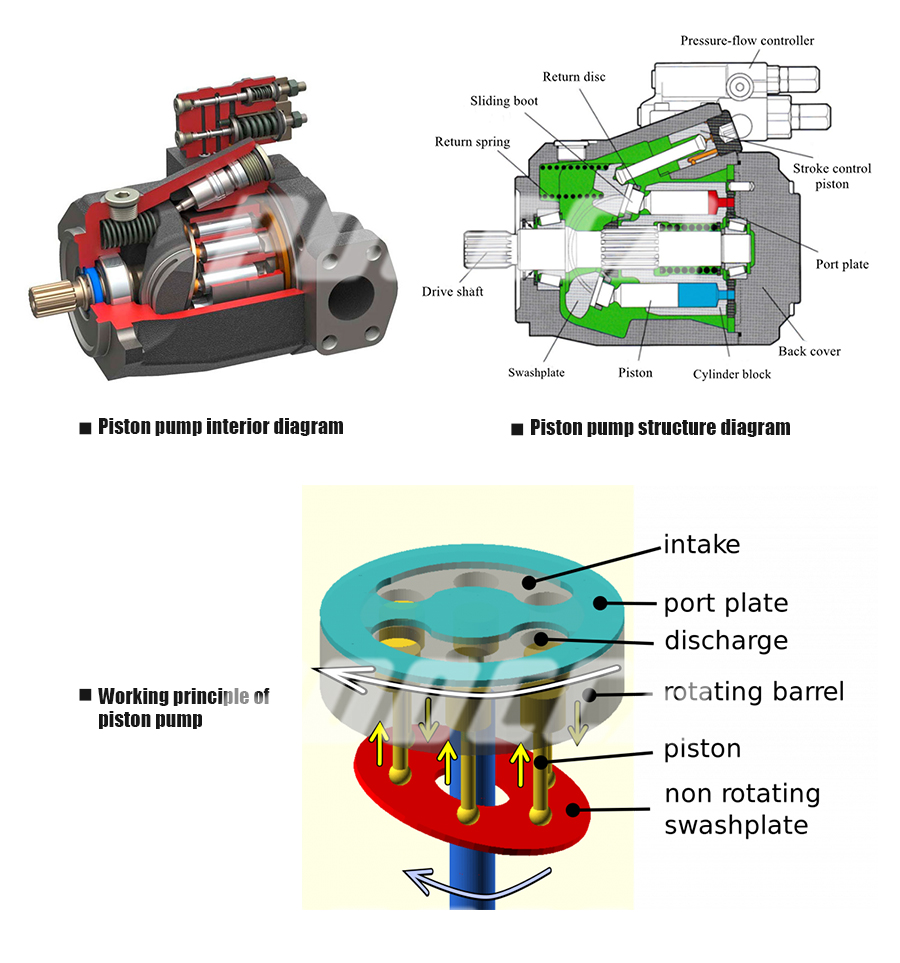

Piston pumps are mainly divided into two types: axial piston pumps and radial piston pumps. Axial piston pumps utilize pistons that move parallel to the axis of rotation, while radial piston pumps have pistons arranged radially about a central axis. This versatility can be adapted to a variety of hydraulic applications to meet the specific needs of industries such as construction, manufacturing and aerospace.

The importance of piston pumps lies in their efficiency and reliability. Their ability to provide precise and controlled fluid output makes them the first choice for applications requiring high pressure and volumetric efficiency. This precision is essential in precision-critical hydraulic systems, ensuring seamless operation of machinery and equipment.

Piston pumps help improve the overall energy efficiency of hydraulic systems. Their design allows for variable displacement, meaning they can adjust the amount of liquid delivered based on the needs of the system. This not only improves performance but also saves energy, in line with modern industry’s growing emphasis on sustainability.

In recent developments, advances in materials and manufacturing processes have further increased the capabilities of piston pumps. Some of the benefits of these innovations include increased durability, reduced maintenance requirements and improved wear resistance.

2.Understand the pistonpump mechanism

Piston pumps are widely used in various industries due to their efficiency and reliability. But how do they work? Let’s take a detailed look at the mechanism and working principle of the piston pump.

The working principle of piston pump is reciprocating motion. It consists of cylinder, piston and connecting rod. The cylinder is divided into two chambers – suction chamber and discharge chamber.

During the suction stroke, the piston moves downward, creating a vacuum in the suction chamber. This vacuum draws fluid into the chamber through the inlet valve. When the piston reaches the bottom of its stroke, the inlet valve closes, trapping fluid inside.

During the discharge stroke, the piston moves upward, pushing fluid out of the discharge chamber through the outlet valve. When the piston reaches the top of its stroke, the outlet valve opens, allowing fluid to flow out.

The reciprocating motion of the piston creates a continuous flow of fluid from the suction chamber to the discharge chamber. The speed of the reciprocating motion can be adjusted by changing the frequency of the driving force, such as an electric motor or hydraulic system.

Piston pumps are commonly used in applications such as fuel injection systems, hydraulic systems and chemical processing plants. Their ability to handle high pressures and flow rates makes them ideal for these demanding tasks.

3.Introduction to POOCCApiston pump series

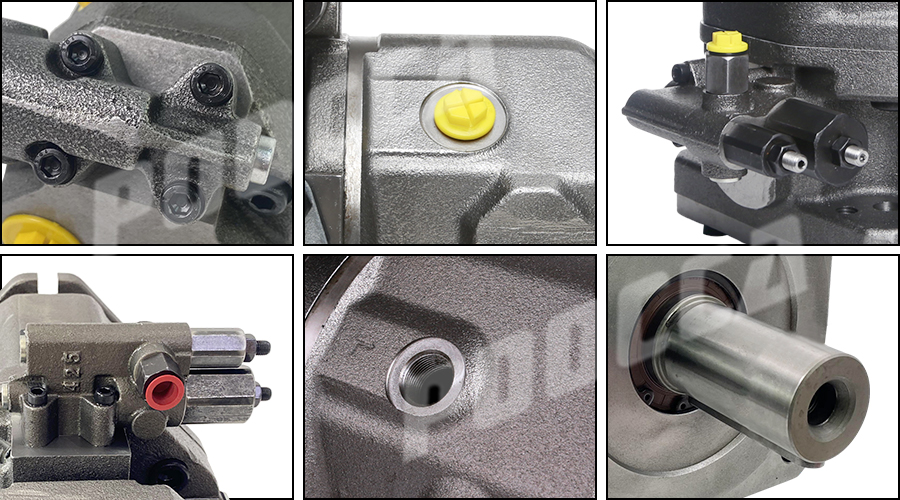

POOCCA sells a variety of hydraulic pumps, among which piston pumps are the most popular among all products. POOCCA’s piston pumps are carefully produced using high-quality materials. Common materials include high-strength alloys and hardened steel to withstand the stress in the hydraulic system. pressure and force. Seals and gaskets are usually made of materials such as nitrile rubber or polyurethane. These materials are chosen because they are compatible with hydraulic oil and can provide effective sealing at different pressures and temperatures. POOCCA is closely related to each link. buckle to ensure quality control during the manufacturing process. Every product needs to be tested. Our production qualification rate is as high as 99.9%, so you don’t need to worry about quality when choosing us, because we have already solved these problems before you worry about them. Solved, and POOCCA has a variety of piston pump brands and models for you to choose from. We sell REXROTH, PARKER, YUKEN, VICKERS, DANFOSS, etc. The most popular ones are Rexroth A10VSO, A4VSO, PARKER PV and other axial piston pumps. There are many In terms of customer choice, whether it is price, quality or delivery time, POOCCA has advantages over its peers.

4.Advantages and disadvantages of using pistonpumps in different industries

Piston pumps have become key players in a variety of industrial applications, offering many benefits while also presenting some challenges. Understanding the strengths and weaknesses is critical for industries that rely on these important partner components.

Advantages of piston pumps:

Superior Positive Displacement: One of the main advantages of piston pumps is their positive displacement design. This ensures consistent and precise fluid output regardless of changes in pressure or viscosity, making it ideal for applications where precision is critical, such as the pharmaceutical and chemical industries.

High-pressure performance: Piston pumps excel at moving high-pressure fluids, a key requirement in industries such as manufacturing and construction. Their ability to generate huge amounts of force makes them an integral part of heavy-duty applications, ensuring reliable operation of hydraulic machinery.

Disadvantages of piston pumps:

Pulsation and Vibration: Although reciprocating motion is precise, it still introduces pulsation and vibration into the hydraulic system. This shortcoming can create challenges in applications that require smooth, continuous flow, such as precision machining or medical equipment.

Maintenance Intensity: Piston pumps are complex mechanical devices that require regular maintenance to ensure optimal performance. This can lead to increased downtime and operating costs, and the industry must weigh the benefits of using these pumps.

Advantages of positive displacement pumps:

Constant flow output: No matter how the system pressure changes, the positive displacement characteristic of the piston pump ensures a constant and reliable flow of fluid. This characteristic makes it ideal for applications requiring stable flow, such as power generation or food processing.

Efficiency under variable conditions: Positive displacement pumps, including piston pumps, maintain efficiency under a wide range of operating conditions. This adaptability is particularly beneficial in industries with fluctuating demand and can improve overall system reliability.

Disadvantages of reciprocating pumps:

Complexity and Cost: The reciprocating nature of piston pumps, while providing accuracy, also increases the complexity of their design. This complexity results in higher manufacturing costs and is more susceptible to wear and tear over time, thus affecting the economic viability of their use.

Limited Flow: Reciprocating pumps (including piston pumps) may have a limited maximum flow compared to some other pump types. This limitation may affect their suitability for applications requiring extremely high flow rates.

5.POOCCA hydraulic manufacturer customer feedback

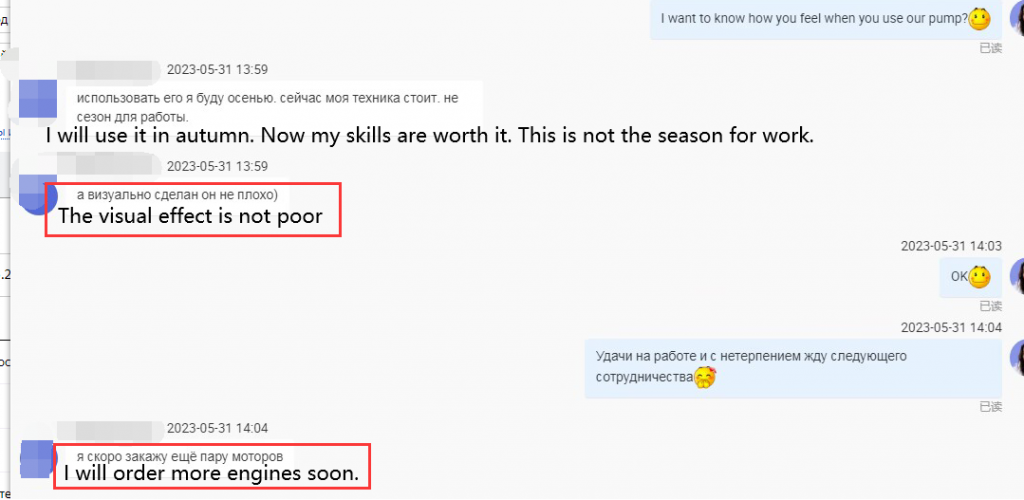

We often have customers who receive feedback after trying the goods for a period of time. This is a customer from Russia. He purchased a batch of parker pv piston pumps. This model includes PV016, PV020, PV023, PV032, PV040, and PV046. , PV063, PV080, PV092, PV140, PV180, PV270, the displacement is 16-270cm3/rev.

6.Piston pump applications in vertical industries: from oil and gas to manufacturing

Piston pumps are widely used in industrial fields, covering many industries such as oil, natural gas, chemicals, pharmaceuticals, and food processing. In oil and gas fields and during oil and gas field development, piston pumps are used to circulate drilling mud. In addition, piston pumps are also widely used in the chemical industry for liquid transportation and metering, such as acid and alkali liquids, solvents, polymers, etc. In the pharmaceutical industry, piston pumps are used for process control and control during pharmaceutical production. Biological Products. Piston pumps are also widely used in the food processing industry to transport various food ingredients and finished products. In short, piston pumps are widely used in industrial fields, providing convenience for production in all walks of life.

7.Based on your specific needs, POOCCA assists in choosing the right hydraulic solution for you.

Choosing the right piston pump is a critical decision that depends on factors ranging from product quality to customization capabilities. In the pursuit of a perfect fit, POOCCA Hydraulics Manufacturers is the hydraulics industry’s best choice, addressing key considerations such as product pricing, quality, delivery time and customization capabilities.

Product Pricing: One of the main considerations when selecting a piston pump is its cost. POOCCA Hydraulic Manufacturer, differentiates itself by offering a competitive and transparent pricing structure. Its range of piston pumps strives to provide value for money, catering to different budgets without compromising on quality.

Product Quality: When it comes to hydraulic components, quality is non-negotiable. POOCCA prioritizes manufacturing excellence and employs strict quality control measures to ensure each piston pump meets or exceeds industry standards. The emphasis on durability and reliability makes their products a trusted choice across a variety of industries.

Delivery Time: Timely delivery is critical to minimizing downtime and maintaining operational efficiency. POOCCA Hydraulic Manufacturers are known for their efficient production processes and commitment to delivery times. The organization is committed to providing customers with piston pumps in a timely manner and reducing the impact of equipment downtime on the business.

Customization capabilities: Every industry has unique needs, and customization capabilities are critical to meeting specific needs. POOCCA Hydraulic Manufacturers specialize in custom solutions, allowing customers to customize piston pumps to their precise specifications. This adaptability ensures seamless integration of the selected pump into different hydraulic systems.

In essence, hydraulic piston pumps harmonize the importance of precision and power in hydraulic systems, allowing machinery in various industries to operate seamlessly. As we conclude our exploration of the inner workings of this critical component, it is clear that the synergy of mechanical engineering and fluid dynamics embodied in the hydraulic piston pump is a testament to the ingenuity that has shaped the modern industrial landscape. Its transformative power to convert mechanical input into hydraulic output underlines its importance as a driving device. The forces driving our technological world.

The piston pump is a hydraulic system device that relies on the reciprocating motion of the piston in the cylinder to change the volume of the sealed working chamber to achieve oil suction and oil pressure. It has the advantages of high rated pressure, compact structure, high efficiency and convenient flow adjustment. Due to its characteristics of high pressure, large flow, and need to adjust the flow, it is widely used in various industrial fields, such as hydraulic presses, engineering machinery, and ships. Piston pumps are generally divided into two types: axial piston pumps and radial piston pumps. Axial piston pumps work by utilizing the volume changes caused by the reciprocating motion of the piston in the piston bore parallel to the drive shaft. of. The working principle of the radial piston pump is that the rotation of the rotor drives the piston to reciprocate in the stator.

Article outline:

1.Introduction

2.Types of POOCCA piston pumps

3.Advantages of POOCCA hydraulic piston pump

4.Hydraulic pump maintenance and repair tips

5.POOCCA piston pump technological innovation

6.Choose the right piston pump

7.Maintenance tips for piston pumps

8.Frequently asked questions

1.Introduction

Definition of piston pump:

Essentially, a piston pump is a device that uses reciprocating motion to move fluid through a hydraulic system. This pumping mechanism plays a key role in various industrial applications.

Significance to the hydraulic industry:

The hydraulics industry relies heavily on piston pumps’ ability to generate high pressures, making them indispensable in powering heavy machinery and equipment.

A brief overview of the hydraulic system:

Understanding the broader context of hydraulic systems provides the foundation for understanding the importance of piston pumps. These systems utilize fluid dynamics to transmit force, making them the basis for countless applications.

2.Types of POOCCA piston pumps

POOCCA hydraulic piston pumps are divided into two types, mainly axial piston pumps and radial piston pumps. Their appearance settings are different. It can be observed from the appearance that these two pump types are positive displacement. Quantity categories, POOCCA will introduce them to you next

a.Axial piston pump:

Structure and working principle

Axial piston pumps use a design where the piston moves parallel to the axis of rotation, forming an efficient pumping mechanism. Exploring its construction and working principles can provide insight into its functionality.

Applications in hydraulic systems

Axial piston pumps are used in a variety of hydraulic systems including heavy machinery, automotive and aerospace due to their high pressure capabilities.

b.Radial piston pump

2.Unique functions and mechanisms

Radial piston pumps have radially arranged pistons with unique functions and a unique pumping mechanism. A closer look at their structure can reveal their advantages in specific industrial settings.

C.Industrial application

Industries benefit when specific features of radial piston pumps improve performance, reliability and fluid control.

3.Advantages of POOCCA hydraulic piston pump

POOCCA hydraulic manufacturer’s piston pump has obvious advantages. We will introduce it to you in terms of efficiency, precision and application.

–Efficiency and Performance

Piston pumps are extremely efficient and provide high performance to hydraulic systems. Their ability to handle varying loads and pressures makes them the first choice in demanding industrial environments.

–Fluid control accuracy

The accuracy POOCCA piston pumps provide in controlling fluid flow helps meet the accuracy required in critical applications such as manufacturing and aerospace.

–Application Versatility

From construction to agriculture, the versatility of piston pumps makes them suitable for a wide range of applications, demonstrating their adaptability in different industries.

4.Hydraulic pump maintenance and repair tips

–Wear problem

Like any mechanical component, piston pumps experience wear over time. Understanding common problems and taking preventive measures are crucial to longevity.

–Maintenance precautions

Regular maintenance is key to ensuring smooth operation of your piston pump. Prompt resolution of issues can minimize downtime and extend the life of these important components.

–Strategies to extend lifespan

Implementing proactive strategies, such as using high-quality fluids and following recommended maintenance schedules, can significantly extend the life of a piston pump.

5.POOCCA piston pump technological innovation

Innovation can start from the integration and sustainability features of smart pumping systems, the hydraulic industry and the Internet of Things, and the integration of smart technology in piston pumps brings advanced monitoring and control capabilities, improving overall system efficiency. When piston pumps are conne

cted to the Internet of Things (IoT), they can provide real-time data insights to enable predictive maintenance and optimize performance. The hydraulics industry is witnessing innovations in piston pump designs that prioritize sustainability, in line with the global push for environmentally friendly technologies

6.Choose the right piston pump,Factors to consider

There are several factors to consider when selecting a piston pump for a specific application. These include required flow, pressure and compatibility with hydraulic fluids. Taking these factors into consideration ensures optimal performance and longevity.

Different applications require different specifications. Matching pump capacity, speed and size to the specific requirements of the hydraulic system ensures efficiency and reliability.

7.Maintenance tips for piston pumps

–Regular inspection

Frequent inspections can help detect potential problems early and prevent unexpected failures. Regular inspections of seals, fluid levels, and overall pump condition can help extend the life of your system.

–Fluid Quality Management

Maintaining high quality hydraulic oil is critical to the proper operation of piston pumps. Regular fluid analysis and timely replacement help improve system efficiency and reduce the risk of wear.

–Troubleshooting common problems

Being able to troubleshoot and solve common piston pump problems is critical. Understanding the root cause of issues such as leaks or unusual noises can help resolve issues quickly and minimize downtime.

8.Frequently asked questions

Q: Are piston pumps and reciprocating pumps the same water pumps?

A: No, while both involve reciprocating motion, unlike other types of reciprocating pumps, piston pumps exclusively use pistons to create fluid motion.

Q: Can the POOCCA piston pump be used in mobile hydraulic applications?

A: Yes, the POOCCA piston pump is highly adaptable and can be used in mobile hydraulic systems, construction machinery, agricultural vehicles and other power equipment.

Q: What are the main factors to consider when installing a piston pump?

A: Proper sizing, correct fluid selection, and following installation guidelines are key considerations when installing a piston pump for optimal performance.

Q: Are there environmentally friendly alternatives to traditional piston pumps?

A: Some hydraulic systems are exploring bio-based environmentally friendly hydraulic oils as alternatives to traditional options to contribute to sustainable development.

Q: How do advances in piston pump technology promote sustainable development?

A: Advanced piston pump technology often focuses on energy efficiency, emission reduction and the use of environmentally friendly materials, in line with global sustainability goals.

The hydraulics industry has experienced a wave of innovation and change in recent years, with axial piston pumps becoming a key force in improving efficiency and reliability. These cutting-edge pumps have become the cornerstone of hydraulic systems, revolutionizing every field with their unparalleled performance and versatility.

Article directory:

**Introduction to POOCCA hydraulic axial piston pump

**Intelligent integration and industry 4.0

**POOCCA Hydraulics actively moves closer to green environmental protection

**Global market trends

**POOCCA solution

**Regulatory environment

**POOCCA Piston Pump Products

1.Introduction to axial piston pump:

The POOCCA axial piston pump is a hydraulic device specially designed for fluid transfer, and its unique structure makes it stand out in the industry. These pumps consist of a series of pistons arranged in a circular arrangement within a cylinder and are capable of delivering high-pressure fluid displacement with extremely high precision. The axial movement of the piston and its ability to adapt to variable loads make axial piston pumps a game-changer in hydraulic applications.

One of the main advantages of axial piston pumps is their efficiency, which is achieved through a combination of POOCCA design elements and advanced materials. The symmetrical arrangement of the pistons ensures balanced load distribution, minimizing wear while maximizing overall performance. This efficiency reduces energy consumption and extends service life, which is a major boon for industries looking for sustainable and cost-effective solutions.

The versatility of axial piston pumps extends beyond their efficiency, making them ideal for a variety of applications. From industrial machinery to mobile equipment and aerospace systems, these pumps have proven their adaptability in diverse environments. Its compact design and modular construction further enhance its suitability for seamless integration into various hydraulic systems.

In addition to efficiency and versatility, axial piston pumps contribute to the overall safety of hydraulic systems. With advanced technologies like pressure compensators and load sensing capabilities, these pumps can adapt to changing conditions, maintaining optimal performance while preventing potential damage. This makes them valuable components in critical applications where accuracy and reliability are critical.

As the industry continues to recognize the benefits of axial piston pumps, manufacturers are investing heavily in research and development to further enhance their capabilities. Innovations in materials, design optimization and smart technologies are on the horizon, promising increased efficiency and functionality. The continuous development of axial piston pump technology is a testament to the dynamic nature of the hydraulic industry.

The advent of the axial piston pump ushered in a new era of efficiency and reliability in the hydraulic industry. As these pumps continue to evolve and find applications in different areas, their impact on the overall performance of the hydraulic system cannot be underestimated. With a focus on sustainability, adaptability and safety, axial piston pumps are a beacon of fluid power innovation, driving the industry toward a more efficient and reliable future.

2.Intelligent integration and Industry 4.0

Axial piston pumps are at the forefront of the Industry 4.0 revolution, leveraging smart technology to improve operational efficiency. Integration with the Internet of Things (IoT) enables continuous monitoring of pump performance. Sensors embedded in the pump can measure variables such as temperature, pressure and fluid quality. This real-time data is then transmitted to a central control system, enabling predictive maintenance. By predicting potential issues before they escalate, industries can significantly reduce downtime and maintenance costs.

3.POOCCA Hydraulics actively moves closer to green environmental protection

In addition to focusing on customers and products, POOCCA Hydraulics is also environmentally friendly. Our POOCCA axial piston pumps also contribute to environmental sustainability in hydraulic applications. The pump’s efficiency translates directly into energy savings, in line with global efforts to reduce carbon emissions. Additionally, advances in pump design reduce the need for hydraulic oil, which in turn minimizes the environmental impact of fluid handling. The industry is increasingly recognizing the importance of environmentally friendly practices, making POOCCA axial piston pumps the first choice for sustainable hydraulic solutions.

4.Global market trends:

The global axial piston pump market is experiencing dynamic trends driven by multiple factors. Emerging economies are experiencing increased industrialization, resulting in increased demand for hydraulic systems in the construction, manufacturing and agricultural sectors. At the same time, advanced economies are working to upgrade existing systems to increase efficiency and reduce energy consumption. The demand for axial piston pumps is also influenced by growing renewable energy applications such as wind and solar, where precise fluid control is critical.

5.Challenges and Solutions:

Although axial piston pumps have many advantages, they also face challenges worth noting. The heat generated during pump operation affects efficiency and system life. POOCCA is constantly researching and developing innovative cooling solutions and materials that can withstand high temperatures. Addressing issues related to fluid contamination through advanced filtration systems is a key aspect of ensuring pump reliability and longevity. Acknowledging these challenges and proposing workable solutions demonstrates the industry’s commitment to continuous improvement.

6.Regulatory environment:

Compliance with industry regulations is critical to widespread adoption of axial piston pumps. Understanding and adhering to standards set by organizations such as the International Organization for Standardization (ISO) ensures the reliability and safety of your pumps. Additionally, proactively anticipating and adapting to potential regulatory changes can position manufacturers and users to become industry leaders. This awareness of the regulatory environment is particularly important as governments around the world focus on environmental and safety standards in industrial operations.

Axial piston pumps are the technological cornerstone of the hydraulic industry, embodying precision, efficiency and adaptability. Throughout the development of hydraulics, the importance of axial piston pumps is evident as they play a key role in various fields. Its design includes pistons arranged in a circular pattern within the cylinder to achieve high-pressure fluid displacement with unparalleled precision. Axial piston pumps remain an important focus as we explore areas such as smart integration, environmental sustainability, global market trends, challenges and the regulatory environment. Its application in Industry 4.0, its contribution to environmentally friendly hydraulic solutions and its versatility in various industries underline its importance. Every time we mention axial piston pumps, we echo their influence in shaping the hydraulic world into a realm of greater efficiency and performance.

7.POOCCA Piston Pump Products

Our POOCCA hydraulic manufacturer sells a wide range of hydraulic pumps. Piston pumps are divided into axial piston pumps and radial piston pumps. Among them, the brands of axial piston pumps are:

Rexroth: A10VSO, A4VSO, A4VSG, A2F, A2FO, A7VO, A11VO, A11VLO, A20VO, A20VLO, A1VO, A17FO.

Parker: PV, PVP, PAVC.

Vickers: PVH, PHQ, PVB, PVXS.

YUKEN: A series, AR series, A3H.

NACHI: PVS piston pump.

Only some brands of models are listed above. If necessary, please send your requirements to our POOCCA hydraulic manufacturers. After receiving your request, we will contact you as soon as possible.

Improved efficiency: Poocca hydraulic piston pumps have high efficiency levels compared to conventional pumps. Its advanced piston design minimizes energy loss, thereby optimizing hydraulic system performance. By improving efficiency, industries can achieve higher productivity while minimizing energy consumption, resulting in significant cost savings.

COMPACT DESIGN: Unlike bulky hydraulic pumps, poocca’s hydraulic pumps feature a compact design that doesn’t compromise on power or performance. This compactness allows for easier integration into existing systems and enables more flexible installation options, especially in space-constrained environments.

Higher Pressure Rating: POOCCA hydraulic piston pumps are designed to offer higher pressure ratings, making them suitable for demanding applications requiring precise control and high force output.

Reduce Noise Levels: Noise pollution is a problem in industrial environments. poocca’s innovative design incorporates noise reduction technology for quieter operation compared to traditional hydraulic pumps. The reduction in noise levels not only improves the operator’s working environment but also complies with increasingly stringent noise regulations.

Extended service life: Durability is a hallmark of poocca hydraulic piston pumps. Our hydraulic pumps use high-quality materials and precision engineering to extend service life, minimizing downtime and maintenance costs. Rugged construction ensures reliable performance even under harsh operating conditions, increasing overall system reliability and longevity.

Precise Control: Precision is important in many hydraulic applications, and poocca hydraulic piston pumps excel at precise control of fluid flow and pressure. Whether it’s a complex machining process or a motion-controlled system, operators can rely on the precision and responsiveness of their pumps to achieve optimal performance.

Versatility: One of the most significant advantages of poocca hydraulic piston pumps is their versatility. Axial variable displacement piston pumps are compatible with a variety of hydraulic oils and can meet different flow and pressure requirements, making them easily adaptable to different applications in various industries. From mobile machinery to industrial automation, its versatility makes it the first choice for many hydraulic pump users.

Integrate with smart technologies: In the industrial age, connectivity and data-driven insights are transforming industrial operations. poocca hydraulic piston pumps are designed with intelligent technology integration that enables remote monitoring, predictive maintenance and real-time optimization. By leveraging data analytics, operators can maximize efficiency, minimize downtime and improve overall system performance.

Environmental Sustainability: With the growing emphasis on sustainability, piston pumps are aligned with environmental initiatives. Its efficient design reduces energy consumption and carbon emissions, helping to make the hydraulic system green and environmentally friendly. In addition, the pump has a long service life, minimizing waste generation and further supporting environmental protection efforts.

POOCCA hydraulic piston pumps represent a significant advancement in hydraulic technology and are trusted for efficiency, reliability and versatility. poocca hydraulics manufacturers are expected to increase productivity, sustainability and competitiveness across industries in the coming years. As the industry continues to develop and impose higher performance requirements on hydraulic systems

POOCCA Hydraulic Manufacturer was established in 2006 and has more than 20 years of experience in the hydraulic industry.

We have up to 1,600 product categories, mainly engaged in gear pumps, piston pumps, vane pumps, motors, hydraulic accessories, hydraulic valves, etc.

Our product order delivery times may vary based on the specific product and its availability.

Regular products take 5-7 days, special products depend on customization time and quantity.

12 months

Our factories are located in Guangdong, Jiangsu and Zhejiang. The annual export volume is as high as 16 million US dollars.

We accept a variety of payment methods including credit card, bank transfer, PayPal, and more.

For large orders, 30% can be paid in advance and the remaining 70% is paid before shipment.

Yes, we offer expedited international shipping options for your convenience. Please contact our sales team to discuss your specific requirements.

Our products comply with industry standards and are certified by ISO, 3C, ROHS, HTT, etc. We are committed to maintaining the highest quality and safety standards.

Yes, we offer product samples and demos to help you choose. Please contact our sales team to arrange.

Yes, we have extensive references and case studies to prove the successful implementation of the product. Please contact our sales team for these resources.

If there is a problem with the quality of the product, it can be returned or exchanged if it complies with the return and exchange policy.

Our products undergo strict quality control and testing procedures. We also have a dedicated quality assurance team to maintain the highest standards. In addition, we regularly invest in research and development to improve our products and stay at the forefront of the industry.

Yes, we offer volume discounts and can provide customized solutions for bulk orders. Please contact our sales team to discuss your specific requirements and pricing options.

You can track your order using the tracking number provided after your order is shipped. Our shipping partners offer tracking services so you can track the progress of your shipment online.

Yes, we provide online installation instructions, maintenance instructions, and technical support resources for our products. Our customer service and technical teams are here to help.

We prioritize sustainability and environmentally responsible manufacturing. Our products are designed with the environment in mind, and we actively participate in sustainability initiatives.

We welcome tours of our facilities and headquarters. Please contact us to arrange a visit and we will be happy to provide insight into our operations and quality control measures.

Consider factors such as flow, pressure and system requirements. Of course, we will also assist you in selection and find the product that suits you.

Hydraulic hoses and fittings are used to carry hydraulic fluid between components in a hydraulic system.

Hydraulic oil transmits power, lubricates components and dissipates heat within the system.

Change and filter hydraulic oil regularly, keep the system clean, and use high-quality filters.

Filtration removes contaminants to maintain system performance and extend component life.

Regular maintenance ensures system reliability, efficiency and minimizes downtime.

Check for leaks, monitor pressure and temperature, and inspect components for wear or damage.

The accumulator stores hydraulic energy, suppresses pressure fluctuations, and can provide emergency power.

Hydraulic valves control fluid flow, pressure, and direction to manage system functions.

Proportional valves provide precise control of flow or pressure, while directional valves manage fluid direction.

Consider factors such as flow, pressure and control requirements to make the best choice.

Hydraulic cylinders are linear actuators used in applications such as construction equipment and manufacturing.

The cylinder extends and retracts when hydraulic oil pressurizes or depressurizes the sides of the piston.

Options include JIC, NPT, SAE and metric fittings for connecting hoses and components.

Regular inspections, proper training and safety protocols are vital to maintaining safety.

Flushing before system assembly or during maintenance removes contaminants and prevents damage.

Proper lubrication, maintenance and compliance with recommended operating parameters are critical.

Seals prevent fluid leakage and maintain pressure within components.

Viscosity affects the fluid's ability to flow and lubricate; it is chosen based on system requirements.

Quick couplers provide a quick, secure connection between hydraulic lines and components.

Consider load, speed, and pressure requirements to select an appropriately sized hydraulic motor.

Hydraulic systems provide high power-to-weight ratio, precise control, and the ability to transmit power over long distances.

Pressure relief valves protect the system from overpressure by releasing excess fluid.

Regular maintenance, monitoring for signs of wear, and following manufacturer's operating and maintenance guidelines can extend the life of components and systems.

Factors to consider include material compatibility, temperature range and specific application requirements.

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us using WeChat

Welcome to contact us via whatsapp