Menu

Close

Menu

Close

Poocca Hydraulic Factory focuses on the maintenance and parts supply of hydraulic pumps, motors, hydraulic cylinders and other hydraulic systems. Our products undergo strict quality control to ensure good performance under various harsh working conditions. The hydraulic parts we provide can be replaced with original ones. The hydraulic parts include Valve Plate, Valve Plate, Cylinderblock, Retainer Washer, Ballguide, Piston Shoe, Retainer Plate, Swash Plate, , Saddle Bearing, Bearing Seat, Drive Shaft, Bush, Internal Gear, External Gear, Side Plate, Charge Pump and other accessories, A10VSO A4VG A6VM and other original parts are in stock in large quantities. Order now and they can be shipped immediately.

Our manufacturing facility houses many CNC machines capable of producing high-quality hydraulic components and replacement parts.

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 2006 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts. With extensive experience in providing power transmission and drive solutions to hydraulic system users around the world, we have a strong reputation in the industry.

Over the past two decades, POOCCAHydraulics has continued to grow and innovate in the field of hydraulics. We have won the trust of domestic and foreign manufacturers and established strong corporate partnerships. Our annual export volume is up to US$16 million and exported to more than 100 countries. We have established long-term and stable cooperative relationships with dealers in more than 75 countries, including the United States, Indonesia, Mexico, Thailand, Russia and Brazil.

Poocca’s hydraulic parts are manufactured to the highest quality standards. From pumps and motors to valves and actuators, hydraulic parts serve a variety of functions designed to optimize performance and ensure smooth operation. The role of hydraulic accessories is to ensure the normal use of the hydraulic system. If any hydraulic part inside is broken, the hydraulic system may not be able to provide power normally. Therefore, hydraulic accessories are an important part for hydraulic equipment in various industries. function, lifespan, etc. play this role.

Hydraulic accessories such as filters, accumulators and coolers are designed to increase system efficiency by keeping hydraulic oil clean, regulating pressure fluctuations and dissipating excess heat. By reducing energy loss and minimizing wear and tear on system components, these accessories help improve overall system efficiency and productivity.

Seals, gaskets and O-rings Hydraulic accessories ensure system reliability by preventing hydraulic oil leaks, maintaining system integrity and preventing potential failure. Properly selected and maintained seals ensure tight sealing at critical points within the system, minimizing the risk of downtime and costly repairs.

Hydraulic accessories such as sight glasses, pressure gauges and breathers provide valuable diagnostic and monitoring capabilities, allowing operators to evaluate system performance and proactively identify potential problems. Quick-connect couplings and hose assemblies simplify maintenance tasks, allowing for efficient repairs and component replacement as needed.

Hydraulic accessories provide the flexibility to customize hydraulic systems to specific application requirements. Control valves, manifolds and diverters allow precise control and distribution of hydraulic oil, allowing for customized performance to meet varying operating needs. Mounting brackets, couplings and adapters help integrate hydraulic components into existing systems or machinery.

Piston assembly: including piston, piston shoe, swash plate and cylinder block.

Valve plate: controls the flow of hydraulic oil in the pump.

Bearings and Bushings: Provide support and reduce friction between moving parts.

Seals and Gaskets: Prevent hydraulic oil from leaking and maintain pressure.

Shaft and shaft seals: transmit the power of the motor and prevent fluid leakage at the shaft interface.

Housing and Housing Components: Encloses and protects the internal components of the pump.

Poocca sells Rexroth A10VSO A4VG A2F, Parker pv and other plunger pump hydraulic accessories

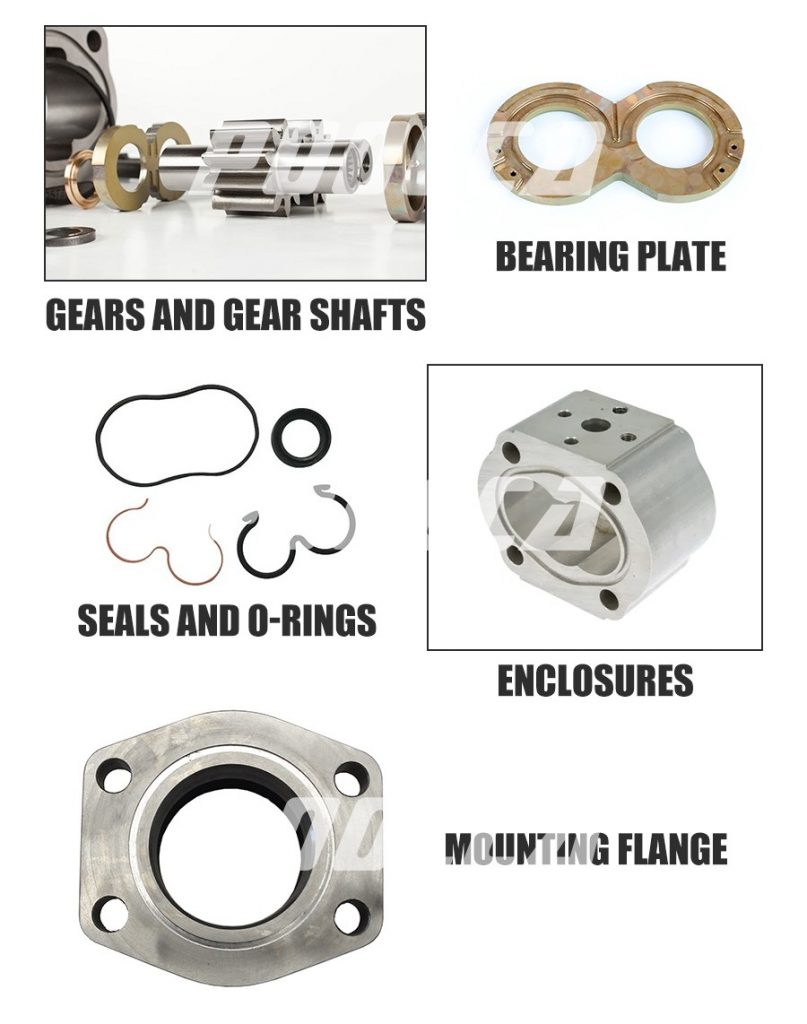

Gears and Gear Shafts: Key components responsible for fluid displacement within the pump.

Bearing plate: supports the gear shaft and bearings.

Seals and O-rings: Ensure proper sealing and prevent fluid leakage.

Enclosures and enclosure assemblies: Provide structural integrity and protection to internal parts.

Mounting flange: Allows the pump to be securely connected to other equipment or machinery.

Gears and Gear Shafts: Key components responsible for fluid displacement within the pump.

Bearing plate: supports the gear shaft and bearings.

Seals and O-rings: Ensure proper sealing and prevent fluid leakage.

Enclosures and enclosure assemblies: Provide structural integrity and protection to internal parts.

Mounting flange: Allows the pump to be securely connected to other equipment or machinery.

Rotor and stator assembly: The core components responsible for converting hydraulic energy into mechanical motion.

Bearings and Bushings: Support rotating parts and reduce friction.

Seals and Gaskets: Maintain hydraulic integrity and prevent fluid leakage.

Shafts and Shaft Seals: Transmit rotational power and prevent fluid leakage at shaft interfaces.

Enclosures and enclosure assemblies: Enclose and protect internal motor components.

Mounting flange: facilitates the installation and connection of the motor to other equipment or machinery.

These accessories are critical to ensuring efficient and reliable operation of hydraulic pumps and motors. Proper selection, installation and maintenance of these components is critical to maximizing the performance and service life of your hydraulic system.

Poocca provides accessories that can replace original parker vane pumps, yuken vane pumps, and vickers hydraulic pumps.

Casing: The casing that surrounds and supports the internal components of a pump.

Rotor: The central rotating part of a pump, usually equipped with slots or grooves to accommodate the blades.

Vanes: Rectangular or trapezoidal vanes that slide in and out of rotor slots to create chambers for fluid discharge.

Spring: A spring mechanism maintains contact between the blades and rotor, ensuring proper sealing and minimizing leakage.

Inlet and outlet: Openings in the housing through which hydraulic oil enters and exits the pump.

End Plate: Plate attached to each end of the pump casing to provide structural support and enclosure.

Bearings and Bushings: Components that support and guide the rotation of the rotor within the pump casing.

Shaft: The central shaft connected to the rotor that transmits rotational motion from a drive source (such as an electric motor or engine) to the pump.

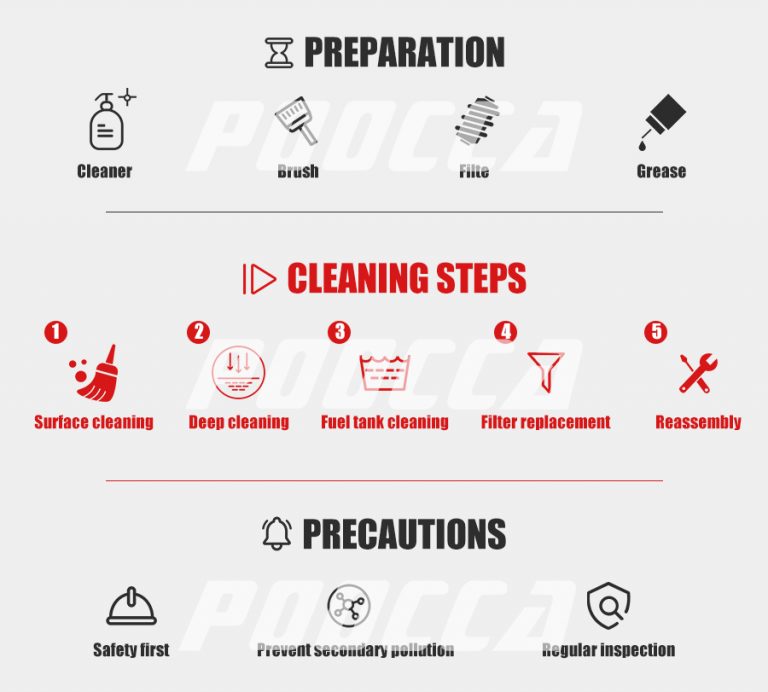

The cleaning of hydraulic parts will directly affect the performance and service life of the equipment. The main pollution comes from dust, dirt and other impurities. Once these pollutants enter the system, they will cause damage to the hydraulic parts and affect the normal operation of the equipment. Therefore, regular cleaning and maintenance of hydraulic components is very necessary. Poocca will give you a brief overview of how to clean hydraulic accessories.

Preparation

Before starting the cleaning work, you should be fully prepared for cleaning:

*Cleaner: Choose a cleaner suitable for your hydraulic components, such as denatured alcohol, diesel or a special hydraulic oil cleaner.

* Brush, cotton cloth or vacuum cleaner: used to remove surface dirt.

* Filter: used to replace hydraulic oil or clean the oil tank.

* Grease: used to lubricate and protect components.

Cleaning steps

* Surface cleaning: Use a brush or cotton cloth dipped in an appropriate amount of detergent, and gently wipe the surface of the hydraulic components to remove dust, dirt and other impurities. Be careful not to use anything too rough to wipe the surface to avoid scratching the surface.

* Deep cleaning: For some hard-to-reach parts, such as the inside of the fuel tank, oil lines, etc., you can use a vacuum cleaner or a high-pressure water gun to clean them. Make sure all impurities are removed.

* Fuel tank cleaning: Cleaning the fuel tank requires more detailed steps. Drain all the hydraulic oil from the tank and use detergent and cotton cloth to clean the inside of the tank thoroughly. Refill the tank with clean hydraulic oil.

* Filter replacement: Replace the hydraulic oil filter or air filter as needed. This is an important step in keeping your hydraulic system clean.

*Reassembly: After all parts are cleaned, reassemble in the original way. Make sure all connections are tight and there are no leaks.

Precautions

*Safety first: During the cleaning process, always pay attention to safety. Avoid wiping with objects that are too rough to avoid scratching the surface; at the same time, avoid contact of the cleaning agent with the skin and eyes.

*Regular inspection: In addition to regular cleaning, the condition of hydraulic components should also be checked regularly. If any abnormalities or damage are found, they should be dealt with in time.

*Prevent secondary pollution: During the cleaning process, make sure the work area is clean and tidy to prevent dust and dirt from entering the hydraulic system again.

*Professional maintenance: For some complex hydraulic components or systems, it is recommended to seek professional help to ensure the quality of maintenance and upkeep.

*Records and training: Establish detailed maintenance records and train operators to improve their awareness and skills in maintaining hydraulic components.

The various parts of the Poocca hydraulic cylinder together form a complete system that allows the conversion between hydraulic pressure energy and mechanical energy. Understanding the characteristics and functions of hydraulic cylinder components will help us better select and use hydraulic cylinders. Of course, if you encounter any difficulties during the selection process, you can contact poocca and we will help you find the correct product model. It mainly consists of the following parts:

Piston Rod: The piston rod is an important component that connects the piston to the load and is usually made of high-strength steel. One end of it is connected to the piston, and the other end is connected to the load through threads or pins. The piston rod bears tension or pressure when the hydraulic cylinder is working, so it needs to have sufficient strength and rigidity.

Piston: The piston is a disc-shaped part within a hydraulic cylinder that is used to transmit the pressure of hydraulic oil to the piston rod. Pistons are made of wear-resistant materials such as polytetrafluoroethylene (PTFE) or polyurethane (PU) to reduce friction and wear. The diameter and stroke of the piston determine the output force and speed of the hydraulic cylinder.

Cylinder Tube: The cylinder tube is the main structure of the hydraulic cylinder and needs to be made of seamless steel pipe. It houses the piston and piston rod internally and is connected to the end cap externally. The inner surface of the cylinder needs to be precision machined to ensure a good fit with the piston. The size and material of the cylinder barrel determine the load-bearing capacity and service life of the hydraulic cylinder.

End Cap: The end cap is a closed component at both ends of the hydraulic cylinder, made of cast iron or aluminum alloy. It has seals inside, such as O-rings or U-rings, to prevent hydraulic oil from leaking. The end cap can also be used to install accessories such as buffers and sensors.

Seals: Seals are key components in hydraulic cylinders used to prevent hydraulic oil leakage. Most hydraulic cylinder accessories are made of rubber, polyurethane or other polymer materials, which have good wear resistance, oil resistance and temperature resistance. The type and size of the seal needs to be selected based on the operating conditions and performance requirements of the hydraulic cylinder.

Guide Bush: The guide bush is the component in the hydraulic cylinder used to guide the movement of the piston rod. It is made of bronze or plastic. It can reduce the friction between the piston rod and the cylinder barrel and improve the smoothness and service life of the hydraulic cylinder. The size and material of the guide sleeve need to be selected according to the diameter of the piston rod and the working pressure of the hydraulic cylinder.

Mounting Parts: Hydraulic cylinders need to be connected to equipment or machines through mounting parts to achieve force transmission and motion control. Installation parts include lugs, flanges, bases, etc., which can be fixed with hydraulic cylinders and equipment using bolts, pins, etc. The design and material selection of the mounting parts need to consider the installation location, load characteristics and usage environment of the hydraulic cylinder.

Poocca sells with original 100% replaceable accessories.

Every part of the hydraulic system together forms a complete energy conversion and control network, realizing complex mechanical movement and force control. To know their control principles, we must first know what hydraulic parts are, so that we can better understand them.

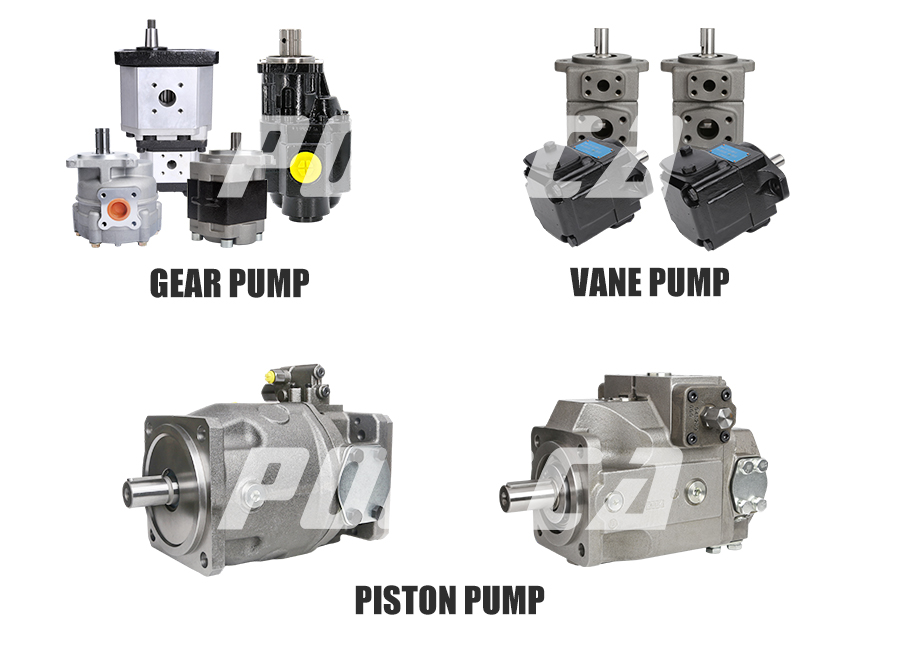

Power Unit: The power unit is the heart of the hydraulic system, providing pressure and flow to the system. A frequently used power component is a hydraulic pump, which converts mechanical energy into liquid pressure energy. There are many types of hydraulic pumps, including gear pumps, vane pumps, plunger pumps, etc. Each pump has its specific application scenarios and performance characteristics.

Control Unit: A control element is used to regulate pressure, flow and direction in a hydraulic system. They ensure that the system operates as intended to meet different job requirements. Control components include pressure control valves (such as relief valves, pressure reducing valves), flow control valves (such as throttle valves, speed regulating valves) and directional control valves (such as reversing valves, one-way valves).

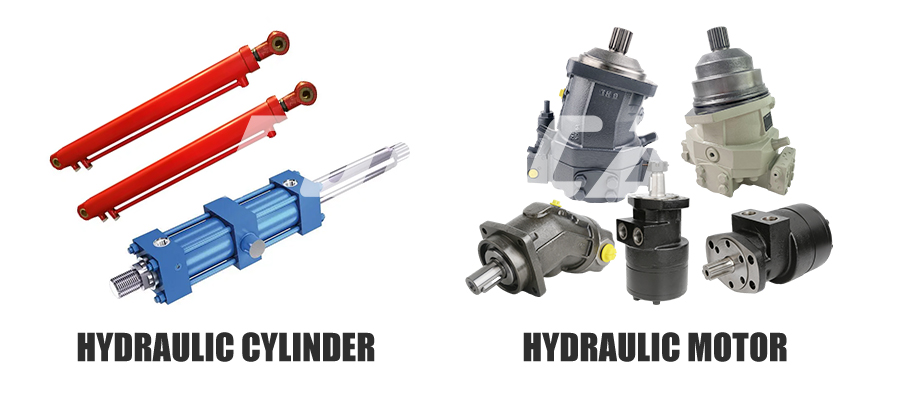

Actuator: The actuator is a component that converts pressure energy in the hydraulic system into mechanical motion. The most common actuators are hydraulic cylinders and hydraulic motors. Hydraulic cylinders are primarily used to produce linear motion, while hydraulic motors are used to produce rotational motion. Their size, shape and materials need to be selected based on specific load requirements and usage environment.

Auxiliary Unit: Auxiliary components are used to support the normal operation of the hydraulic system, including tanks, filters, coolers, accumulators, pipelines and joints, etc. Although these components do not directly participate in energy conversion, they are crucial to ensuring the stable operation of the system and extending its service life.

Working Fluid: The working medium of a hydraulic system is usually hydraulic oil, which is responsible for transmitting pressure and lubrication of various components. The selection of hydraulic oil needs to consider various factors such as viscosity, anti-wear, and oxidation resistance to ensure efficient operation and long-term stability of the system.

If you want to know more, please contact poocca. We provide you with high-quality and affordable hydraulic accessories.

For businesses and individuals looking to maintain, repair, or upgrade their hydraulic systems, access to high-quality parts is critical.

Finding a reliable source of hydraulic parts is critical to ensuring the smooth operation and longevity of your hydraulic system. You can purchase through poocca’s website and related contact information, and send us the product model, quantity, destination and other information you need. Poocca will have a dedicated person contact you. In addition to hydraulic accessories, we also sell hydraulic pumps, hydraulic motors, hydraulic valves and other hydraulic transmission systems.

POOCCA Hydraulics is a powerful hydraulic enterprise integrating R&D, manufacturing, sales and maintenance. Its products are exported to more than 120 countries. Its quality, price and service are deeply recognized and trusted by customers.

Welcome to contact us using WeChat

Welcome to contact us via whatsapp