Understanding Hydraulic Low Pressure Gear Pumps

Definition and Core Function

A Hydraulic Low Pressure Gear Pump is a gadget that shifts liquid using gears. It’s built for gentle systems needing calm, constant fluid flow. These devices matter greatly in many trades. They shine where cheap, trusty liquid handling is key. You’ll spot them in farm tools, factory machines, and car setups. Folks pick them for their plain build, sturdy nature, and low price. With fewer bits moving, they demand less fixing. Plus, setting them up is a breeze.

Types of Hydraulic Gear Pumps

Two chief kinds of hydraulic gear pumps exist: outer and inner gear types. Outer gear pumps use twin gears spinning opposite ways. They’re famed for being straightforward and budget-friendly. Inner gear pumps, though, feature one outer gear turning inside a bigger inner one. They run quieter and more smoothly. Low pressure versions differ from high-force ones. They work with less push. They suit setups avoiding huge power. A hydraulic gear pump low pressure model often saves power. It fits delicate gear nicely.

How a Hydraulic Low Pressure Gear Pump Operates

The Mechanics of Positive Displacement

A Hydraulic Low Pressure Gear Pump runs on positive displacement rules. This means it shifts a set liquid chunk per gear spin. As gears twirl, they snag fluid between their teeth and the pump shell. This makes a pull effect. It drags liquid in and then shoves it out. Since each move shifts a fixed amount, the stream stays even.

Step-by-Step Working Process

In the pull phase, gears split apart leaving the mesh spot. This forms a vacuum. It sucks liquid into the entry. Then, the liquid gets caught between gear teeth and the cover. As gears keep spinning, they haul the liquid around the pump’s rim to the exit side. When gears mesh again, the gap shrinks. This pushes liquid out the exit hole. The cycle loops endlessly as gears turn. It keeps a steady liquid stream flowing.

Key Components Explained

Core pieces of a low pressure hydraulic gear pump include gears, the shell, entry and exit holes, and seals. Gears, often crafted from steel or bronze, boast specially shaped teeth. These boost how well it runs. The shell keeps all bits steady and guides liquid flow. Each part’s quality sways performance. Top-notch stuff and smart shaping mean longer life and better work.

Advantages of Hydraulic Low Pressure Gear Pumps

Simplicity and Durability

A top perk of a Hydraulic Low Pressure Gear Pump is its basic build. Fewer pieces mean less risk of breaking or wearing down. This makes them great for harsh spots. Think dusty, gritty, or wildly hot or cold places. Their tough frame lets them hum along ages with scant repairs.

Energy Efficiency and Steady Flow

These pumps also spare power. As positive displacement gadgets, they waste little energy running. They push liquid at a calm pace too. No wild bursts happen. This suits setups needing exact liquid delivery, like oiling systems in gear.

Self-Priming Capability

Another plus is their self-priming trait. They can kick off moving liquid even with air in the path. This cuts setup time. It also eases operation.

Common Applications of Low Pressure Hydraulic Gear Pumps

Industrial and Agricultural Uses

These pumps often aid farming and factory tasks. They drive sprayers, water systems, and belts. They’re spot-on for light hydraulic setups needing steady liquid shifts. One tale shows farmers using a Hydraulic Low Pressure Gear Pump for watering gear. It helps them handle water use and lift crop yields.

Automotive and Manufacturing

In autos and trucks, these pumps fuel oiling and cooling setups. In plants, they power small gear and shift liquids in making lines. Their quiet hum and even flow make them ace for these spots.

Maintenance Tips for Hydraulic Gear Pumps

Preventing Common Failures

To keep a hydraulic gear pump low pressure system humming, routine peeks are vital. Cavitation, where air bubbles pop up in liquid, is a frequent snag. You dodge it with the right liquid kind and steady entry pressure. Checking seals and gears for wear matters too. Swap out banged-up bits fast to skip bigger woes.

Optimal Fluid Selection

Picking the perfect liquid counts. Some pumps thrive with oil. Others manage water-glycol blends. A wrong pick can sap smoothness and hurt the pump. Stick to the maker’s tips always.

Choosing the Right Hydraulic Low Pressure Gear Pump

Key Specifications to Consider

When nabbing a Hydraulic Low Pressure Gear Pump, eye the flow pace, pressure span, and heat limits. It should match your system’s liquid too. Matching these ensures it runs swell and lasts long.

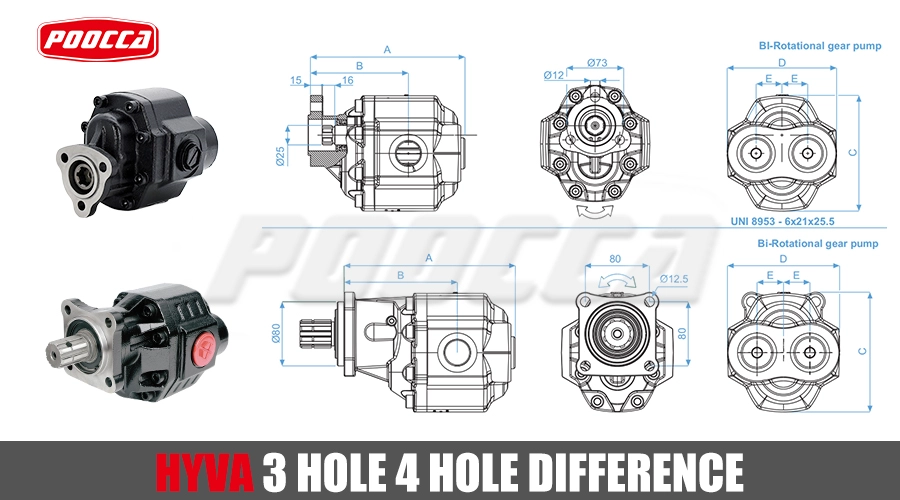

Benefits of Customization (Poocca Hydraulic Low Pressure Gear Pump)

Poocca crafts custom fixes for odd needs. With over 20 years in the game, they shape pumps for quirky tasks. Tailoring can hike smoothness and spare power. Poocca offers swift shipping, plant pricing, and a 12-month promise. This marks them as a trusty low pressure hydraulic gear pump source.

Frequently Asked Questions

Can a Low Pressure Gear Pump Handle High-Viscosity Fluids?

Sure, but limits apply. Too-thick liquid might strain it. Beefier gears or tweaked materials can aid with denser stuff.

How Long Do Hydraulic Gear Pumps Last?

With solid care, a low pressure hydraulic gear pump endures years. Liquid quality, running heat, and regular tending sway its life.

Why Partner with Poocca for Your Hydraulic Pump Needs?

Expertise You Can Trust

Poocca brings over 20 years crafting hydraulic pumps. They aim to build tough, wallet-friendly setups. They team with clients to shape pumps that fit just right. As a top Hydraulic Low Pressure Gear Pump supplier, they dish out savvy advice and backup.

Creative CTA: “Need a Custom Hydraulic Solution? Let’s Build It Together!”

Want a steady gadget to shift liquids in your setup? Poocca stands ready to aid. Reach out for a free chat or pump peek. Kick off boosting your system now. Enjoy a 12-month promise too. Let’s craft the perfect fix together.