Introduction to Hydraulic Gear Pumps

Hydraulic systems form the backbone of the majority of industrial operations, providing power to heavy machinery and precision work. At the very center of such systems is often the hydraulic gear pump, a rugged and simple positive displacement pump. Hydraulic gear pumps utilize the meshing of gears to propel fluids and provide a specific volume of flow for various applications. They are also adaptable because they can handle various liquids from chemicals and oils to slurries. The use of various industries by these pumps is the origin of their use in modern engineering.

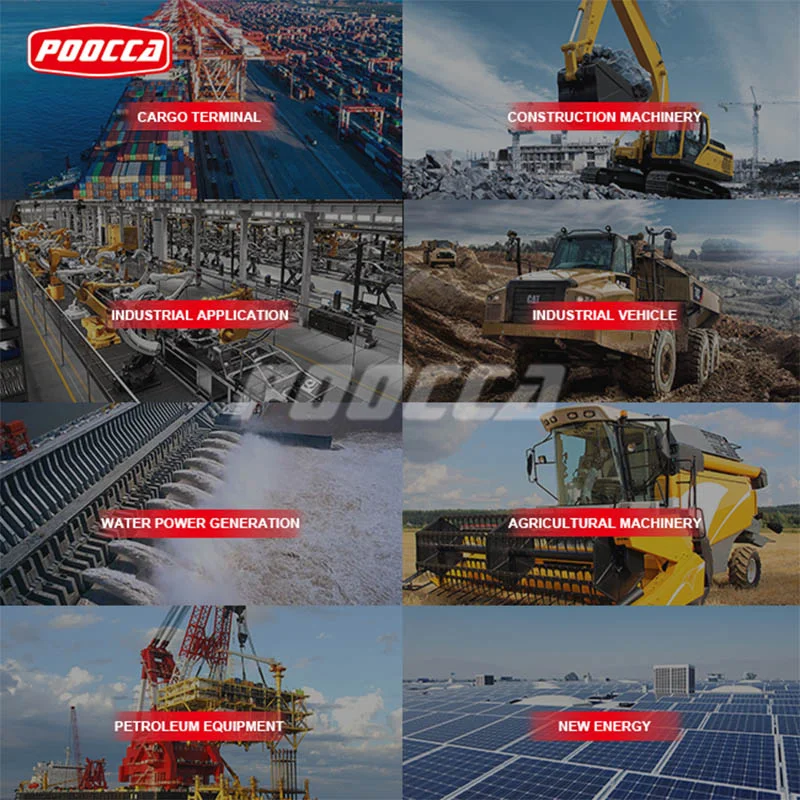

Industries That Use Hydraulic Gear Pumps

The strength and adaptability of hydraulic gear pumps make them unrivaled in most firms. Let us talk of some of the most important industries where hydraulic gear pumps are a critical element.

Industrial and Manufacturing Application

Hydraulic gear pumps are an essential element in manufacturing firms where they power various equipment. They supply hydraulic energy to actuators, presses, and other machinery. For example, in the process of molding plastics, gear pumps allow plastic molding machines used to shape raw materials into a final product to run continuously. The ability to give constant output flows when being used under pressure conditions makes the use of them perfect for work under such pressures. Manufacturing organizations rely on how effectively hydraulic gear pumps work in ensuring that functions are being accomplished in smooth, effective ways.

Agriculture Industry

The agricultural industry also depends on the use of hydraulic gear pumps. They power equipment such as sprayers, tractors, and harvesters that require high-pressure hydraulic systems to power attachments, transport, and lift. The pumps offer smooth flows of farming equipment, which allows farmers to perform operations optimally. Gear pumps’ operation around the clock is crucial during planting and harvesting seasons.

Construction and Mining Machinery

Hydraulic gear pumps are extremely crucial in mining and construction sectors. These pumps are used in heavy equipments such as cranes, bulldozers, loaders, and excavators. These pumps are where the power in heavy equipments is obtained to load heavy loads or make precise movements. For ease of operation in industries, these pumps are a necessity whether it is digging foundation or material transfer in a construction site.

Aerospace Applications

Although less common than in other applications, hydraulic gear pumps are also utilized within the aerospace field. hydraulic gear pumps are used in aircraft landing gear hydraulic systems and other equipment, making the power to operate smooth and perfect. The pumps within such applications are required to be highly dependable and perform under the worst possible conditions.

Automotive Industry

Automotive employs hydraulic gear pumps in various applications, for example, power steering and brake charge systems. Automotive uses pumps to gain fine and fast response control, a very important aspect of automobile safety and performance. Automotive relies on gear pumps as they are compact in size, ideal for inclusion in complex automobile designs.

Oil and Gas Industry

The gear pumps are also applied in the oil and gas industry for various services, including pumping lubricating oils, fuel, and crude oil. The pumps are utilized for pumping liquids in production, processing, and delivery system stages. Products being volatile, leak-free operation and reliability are of paramount importance and therefore make gear pumps a great option.

Chemical and Petrochemical Processing

They find applications in ship construction and maritime operations for the pumping of corrosive and thick chemicals across a wide range. Because they consist of heavy duty material in most instances stainless steel and cast iron, they are employed in the transfer of corrosive fluids. They are applied in chemical plants in the processing of high viscosity fluids and control of fluid flow rates at a constant level irrespective of fluid density change.

Shipbuilding and Marine

Shipbuilding and marine uses hydraulic gear pumps for propulsion, steering, and other hydraulic drives. Safe and proper operation of ships and boats depend on pump performance and life. Gear pumps are utilized in small pleasure craft and large commercial vessels as a part of the hydraulic system.

Food Processing and Packaging

In food packaging and processing, hydraulic gear pumps are utilized to control fluids that are utilized at various stages of production. Hydraulic gear pumps can be utilized to control various viscous fluids utilized in food processing and can deliver an extremely stable and accurate output. Hydraulic gear pumps are utilized heavily in food packaging machines, beverage manufacturing, and other food processing processes.

Advantage of Hydraulic Gear Pumps

The reason why gear hydraulic pumps are used is that they have some significant advantages:

Simplicity and Strength: Gear pumps are made very simply with fewer moving parts, therefore firm and strong.

Economical: They are less expensive to manufacture and keep in working order than other hydraulic pumps.

High Pressure Capability: Despite the simplicity, gear pumps are capable of withstanding quite high pressure.

Versatility: They are versatile as they can be applied with different fluids of different viscosities.

Compact Size: They have a compact size due to which they are easy to use in places where space is not available.

Hydraulic Gear Pump Maintenance and Reliability

Though hydraulic gear pumps are as tough as they come, they should be serviced periodically so that they are able to enjoy their long life as well as trouble-free operation. They should be checked periodically for leakages, vibrations, and abnormal sounds. The oil should also be contaminant-free, lubricating oil changed periodically, and idling in excess prohibited. It can be properly repaired and will go on serving perfectly without needing costly repair or replacement.

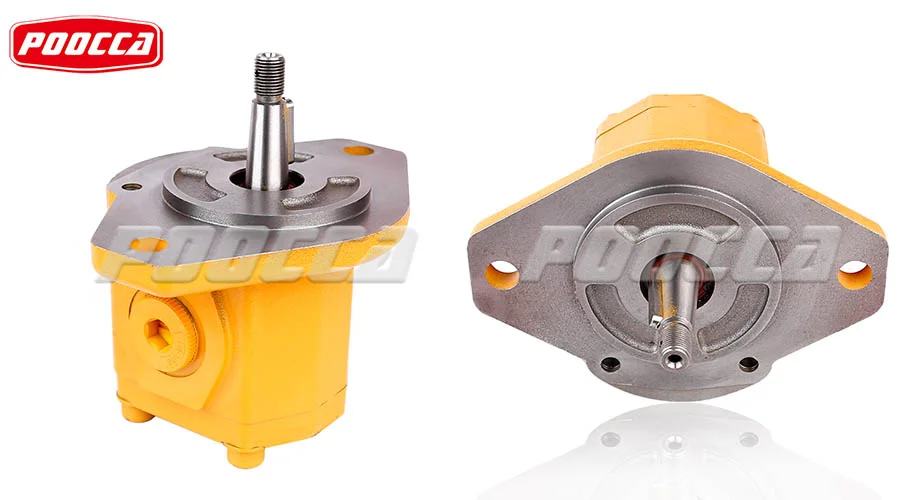

POOCCA Hydraulic Gear Pumps

POOCCA hydraulic is a most reliable hydraulic company with over 20 years’ experience in manufacture, sales, and research and development of hydraulic components. POOCCA gear pumps are defined by the special requirements of various industries and comprise a trustworthy power source to drive hydraulic motors, cylinders, and other actuators. It possesses the newest noise control technology to provide assurance for the removal of running noise. POOCCA provides a variety of models and types of gear pumps with 12-months product warranty as an indication of their confidence in the quality of their product.

Conclusion

Gear pumps hydraulic are the pillar of industry nowadays and a very crucial key in many industries.

They are robust in nature, easy to install and easy to apply on a low level of investment and thus are on priority in any majority of hydraulic applications. From operating heavy equipment in the construction sector to delivering precise movement in manufacturing, these pumps are very valuable to them. Proper maintenance should be ensured so that such pumps are there for decades to come as well as operate at optimum efficiency. Industries, if they are opting for quality pumps by renowned brands like POOCCA, can be a source of steady hydraulic power to the process.