In the general family of industrial equipment, hydraulic systems are a power source. Work is done by hydraulic power, from the earth-moving equipment involved in construction work to factory precision machinery. A part of many aspects of hydraulic systems is understanding the distinction between open loop and closed loop hydraulic systems, specifically for individuals with an interest in quality manufacturers or suppliers of products of hydraulic systems.

Open Loop Hydraulic Systems: Fundamentals

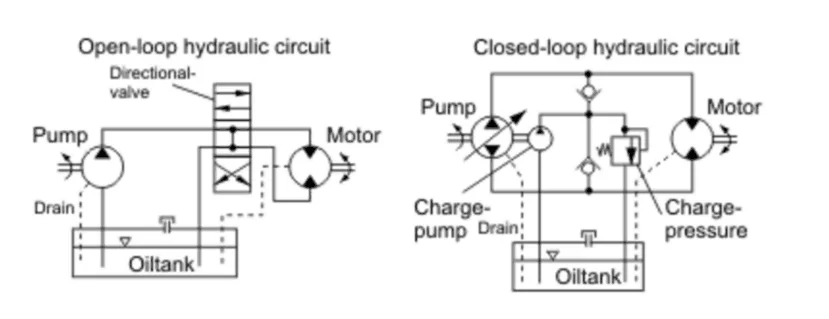

An open loop hydraulic system operates comparatively simply. At its most elementary, a pump sucks hydraulic fluid from a reservoir and forces it through a group of valves to an actuator, either a hydraulic motor or a hydraulic cylinder. Once the fluid has fulfilled what it has been designed to do, it cycles back to the reservoir. That simple action forms the foundation of open loop systems.

An open loop system design is straightforward. It can be as simple as a pump, control valves, a reservoir, and an actuator. The pump provides the pressure to move the fluid, control valves modulate the fluid supply to the actuator, and the reservoir holds the fluid and acts as a medium for heat transfer.

Cost-effectiveness is also one of the biggest benefits of open loop systems. Since they have fewer components and a less complex design, they cost less to purchase and install. And since they’re simple, they’re also easy to maintain, even for a non-technically oriented person. Open loop systems aren’t all positive, however. Energy efficiency is one of the biggest issues. Since the pump operates at constant speed all the time, there is a great wastage of energy, especially if the actuator is not loaded considerably. Secondly, open loop systems have very poor control precision. For example, in a conveyor system where the speed needs to be precisely controlled, an open loop system cannot maintain constant speed.

Closed Loop Hydraulic Systems: A Closer Insight

Closed-loop hydraulic systems are an advanced choice. On this type of system, there is a feedback loop established. Position, velocity, or force sensors provide feedback to a controller. The controller adjusts the pump output in trying to maintain operating conditions to desired level.

A closed loop system is more advanced in design than an open loop system. It has, apart from the general components like a pump, actuator, valves, and reservoir, feedback sensors and a controller. The additional components communicate with each other in a way that produces precise and sensitive performance.

Closed loop systems have many advantages. Their control accuracy is far greater than that of open loop systems. In a CNC machine, for instance, where high speed and position control accuracy is required, a closed loop hydraulic system can deliver micron-level accuracy. They also achieve greater energy efficiency. By controlling the pump output in proportion to the load, closed loop systems can reduce energy consumption by an extremely high ratio. But these benefits come with a price tag. Closed loop systems are also more expensive to purchase and install due to the highly advanced parts. Closed loop systems are also more difficult to repair since it will take more technical skill to maintain the sensors and controllers operating at their full capability.

Primary Distinctions Disclosed

Accuracy in Control

The primary difference between open loop and closed loop systems is the accuracy of control. The open loop system lacks the self-correcting element based on actual performance by the actuator. Thus, open loop systems are less accurate and the output is not the same as the set point. Closed loop systems use feedback and constantly change pump output to maintain the actuator exactly as commanded.

Energy Efficiency

Open loop systems are not energy efficient since the pump operates at a constant rate continuously regardless of the load. This is wastage of a lot of energy, especially during low demand. Closed loop systems are able to sense the load and reduce the output of the pump when there is less power needed. Load – sensing features in closed loop systems are what provide them with better energy management.

Cost

Open loop systems are cheaper. Fewer and less complex components translate into cheaper installation costs as well as manufacturing. Closed loop systems with their advanced sensors and controllers are more expensive. The cost differential may turn out to be an influencing factor for low – budget firms, particularly where high – precision control is not a requirement.

Applicable Scenarios

Open loop systems are suitable in those applications where low cost and simplicity are of greater significance than very precise control. Simple material handling devices like forklifts are examples where lifting loads and not fine positioning are of prime significance. Closed loop systems are most suitable in applications for high precision control, i.e., injection molding machines and precision machining tools.

Find POOCCA Hydraulic Systems

In the market of reliable hydraulic systems products, POOCCA is a name to reckon with. POOCCA is a well-known brand name in hydraulics with over 20 years of experience in hydraulics. They deal in a wide range of products like gear pumps, piston pumps, vane pumps, hydraulic motors, and valves.

POOCCA offers high-quality products that are low-cost and have an excellent warranty. Whether you are looking for an open loop or closed loop hydraulic system part, POOCCA can deliver. Technical consultancy and professional customization services are offered as well to ensure that you obtain the best product for your own particular use.

Conclusion

In conclusion, awareness of the difference between open loop and closed loop hydraulic systems makes you a savvy purchaser when purchasing a purchase of hydraulic products. Open loop systems are low-cost and simple, but closed loop systems are high-precision controlled and energy-saving. Depending on your application requirements, budget limitations, and long-term goals, you can choose the right system. And if you are looking for a good supplier, POOCCA’s variety of products and enhanced services render it the best hydraulic company.