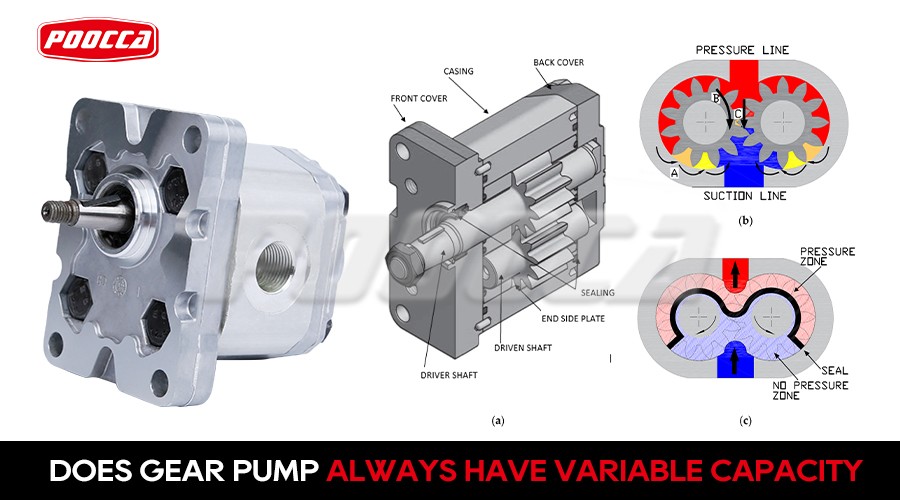

Gear pumps are renowned for their efficiency and reliability, serving as indispensable components across a breadth of industries. These devices operate by utilizing the meshing action of gears to transfer fluids. The paramount importance of efficiency in gear wheel pumps is underscored by their impressive volumetric efficiencies, which can reach up to 91%. In this blog, we will examine the intricate mechanisms at play within these pumps, identify common failures that adversely impact performance, and offer insights into optimization techniques designed to enhance overall efficiency.

Understanding Gear Pumps

Gear pumps, often referred to as gear wheel pumps (GWP), represent a critical technology in the domain of fluid transfer. These pumps function by meticulously metering molten resin at the low-pressure inlet side and subsequently discharging it at elevated pressures. The efficient transport mechanism is facilitated through the intermeshing gears within the pump. Esteemed for their precision and dependability, gear pumps are widely adopted across multiple industries.

Gear pumps are currently used in the industrial field. Since 1997, POOCCA Hydraulic (Shenzhen) Co., Ltd. officially established as a comprehensive hydraulic service provider, we focus on the development, manufacturing, maintenance support services and sales of hydraulic pumps, motors, valves and related components.

Recognizing Gear Pump Issues

Identifying Wear and Tear Signs

- Inspect the gears for any signs of wear, such as pitting or scoring, which can affect the smooth operation of the pump.

- Check for any leakage around the pump casing, as it could indicate worn-out seals or gaskets that need replacement.

- Monitor the noise levels during operation; unusual sounds like grinding or whining may signal internal damage to the gears.

Noticing Contamination Indicators

- Look for discoloration in the fluid being pumped, which could suggest contamination from external sources.

- Observe any unusual odors emanating from the pump, as they might indicate a chemical reaction or foreign substances in the fluid.

- Check for irregularities in fluid viscosity, as contaminants can alter the consistency and flow properties of the liquid.

Addressing Gear Pump Problems

Implementing Regular Maintenance

- Establish a routine maintenance schedule to ensure timely inspection and servicing of all pump components.

- Clean the gears and housing regularly to prevent debris buildup and maintain optimal performance.

- Replace worn-out parts promptly to prevent further damage and extend the lifespan of your gear pump.

Ensuring Proper Operation

- Monitor the operating conditions regularly to detect any deviations from normal performance parameters.

- Adjust pump speed and flow rates as needed to match specific application requirements and optimize efficiency.

- Train personnel on proper handling and maintenance procedures to minimize errors and maximize gear pump longevity.

Enhancing Gear Pump Efficiency

Optimizing Pump Speed

When gears in a gear pump operate at their maximum design speed, they exhibit peak efficiency. This optimal speed minimizes slip and enhances the volumetric efficiency of the pump. Operating a gear pump at lower speeds or flow rates can reduce its volumetric efficiency. To optimize the pump speed, users should consider the specific requirements of their application.

Impact on Efficiency

Operating a gear pump at its designated speed has a direct impact on its overall efficiency. At higher speeds, the pump can achieve better performance in terms of fluid transfer and pressure generation. However, deviating too far from the recommended speed range can lead to decreased efficiency and potential issues with fluid handling. Therefore, maintaining an optimal operating speed is crucial for maximizing the efficiency of a gear pump.

As a pivotal component of high-efficiency hydraulic systems, the gear pump stands among the primary production outputs of POOCCA Hydraulic (Shenzhen) Co., Ltd. Over the past two decades, our unwavering commitment to innovation in the hydraulic sector has garnered the trust and collaboration of both domestic and international manufacturers. We pride ourselves on fostering robust corporate partnerships and are steadfast in our dedication to advancing the hydraulic industry.

Methods to Optimize

- Monitor: Regularly check and adjust the operating speed of the gear pump to ensure it aligns with the manufacturer’s recommendations.

- Calibrate: Use the precision instruments to calibrate the speed of pump accurately, taking into account factors such as viscosity and flow requirements.

- Test: Conduct performance tests at different speeds to determine the ideal operating range for your specific application.

- Adjust: Fine-tune the speed settings based on real-time feedback and performance metrics to achieve optimal efficiency.

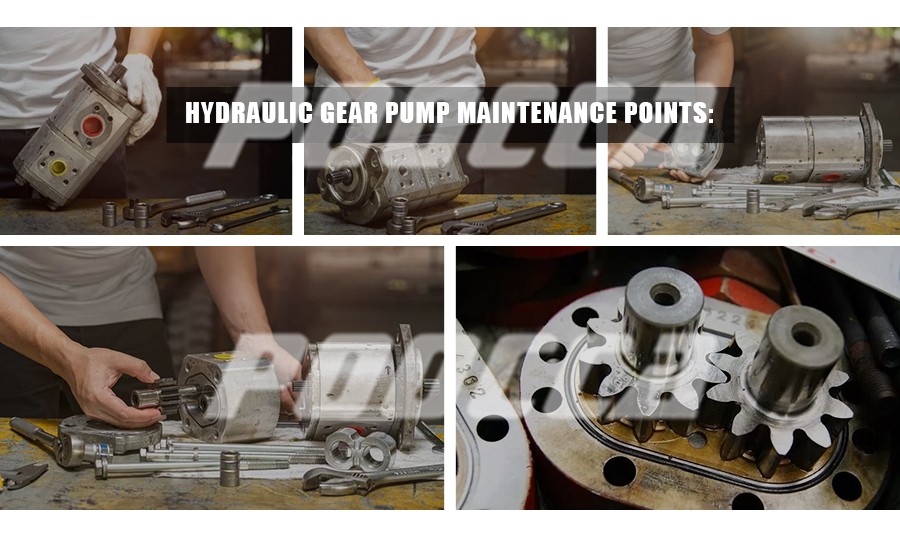

Cleaning a Gear Pump

Maintaining cleanliness is essential for ensuring the longevity and efficiency of a gear pump. Regular cleaning not only prevents debris buildup but also safeguards against contamination that could compromise performance.

Importance of Cleaning

Proper cleaning procedures are vital for preserving the functionality of a gear pump over time. By removing dirt, residue, and other impurities from internal components, users can prevent blockages and maintain smooth operation.

Cleaning Procedures

- Disassembly: Carefully disassemble the gear pump according to manufacturer guidelines, ensuring all parts are accessible for cleaning.

- Inspection: Thoroughly inspect each component for signs of wear or damage before proceeding with cleaning.

- Cleaning Solution: Use a suitable cleaning solution recommended by the manufacturer to cleanse gears, housing, and other parts effectively.

- Rinsing: After cleaning, rinse all components thoroughly with clean water to remove any remaining residue or cleaning agents.

- Drying: Allow each part to air dry completely before reassembling the gear pump to prevent moisture-related issues.

Selecting a Gear Pump for Viscosity

Choosing the right type of gear pump based on fluid viscosity is crucial for achieving optimal performance and efficiency in various applications.

Matching Pump to Fluid

Matching a gear pump to the viscosity of the fluid being handled is essential for efficient operation. Different types of gear pumps are designed to accommodate varying viscosities, ensuring smooth pumping action without excessive resistance or strain on internal components.

Benefits of Proper Selection

- Efficiency: Properly matching a gear pump to fluid viscosity enhances overall operational efficiency by reducing energy consumption and minimizing wear on moving parts.

- Reliability: Selecting an appropriate gear pump helps maintain consistent flow rates and pressure levels, leading to reliable performance in diverse operating conditions.

- Longevity: By choosing a gear pump that aligns with fluid viscosity requirements, users can extend the lifespan of their equipment and reduce maintenance costs over time.

In conclusion, a comprehensive understanding of the operational principles behind gear pumps is essential for optimizing their performance. Regular maintenance and correct operation are vital in preventing failures and ensuring sustained efficiency over time. Emerging industry developments stress the significance of energy-efficient solutions to accommodate rising demands. Therefore, prioritizing the maintenance of gear pump efficiency is crucial for minimizing energy consumption and boosting overall productivity.