What Are Variable Displacement Piston Pumps?

Defining the Core Technology

Variable displacement piston pumps are hydraulic pumps capable of changing their flow rate based on system requirement. Unlike fixed displacement pumps, which have constant output, these devices change displacement dynamically. It is this flexibility that ensures maximum energy saving, minimizes heat generation, and optimizes equipment life.

In the past, hydraulic systems completely depended on fixed displacement pumps such that a majority of wastage of energy used to take place when there is a change of demands. Technology in variable displacement made it possible for such systems to be cost-effective by manipulating the output of the pump for purposes of changing the demands at the time. Such pumps currently form a major requirement in the construction, manufacturing, and transportation industries.

How Variable Displacement Piston Pumps Work

The Working Principle Behind Adjustable Flow

The primary task of a variable displacement piston pump hinges on its capacity to modify the flow of hydraulic fluid. This shift is managed by the swashplate angle, which controls how far the pistons travel inside the cylinder block. When the angle grows larger, more fluid gets pumped. Conversely, when it shrinks, the flow decreases.

A pressure compensation mechanism oversees this adjustment. If system demand falls, the pump cuts back its output, avoiding wasteful energy use. Hydraulic feedback systems are crucial here. They sense pressure changes and tweak the pump’s function automatically, keeping performance steady and reliable.

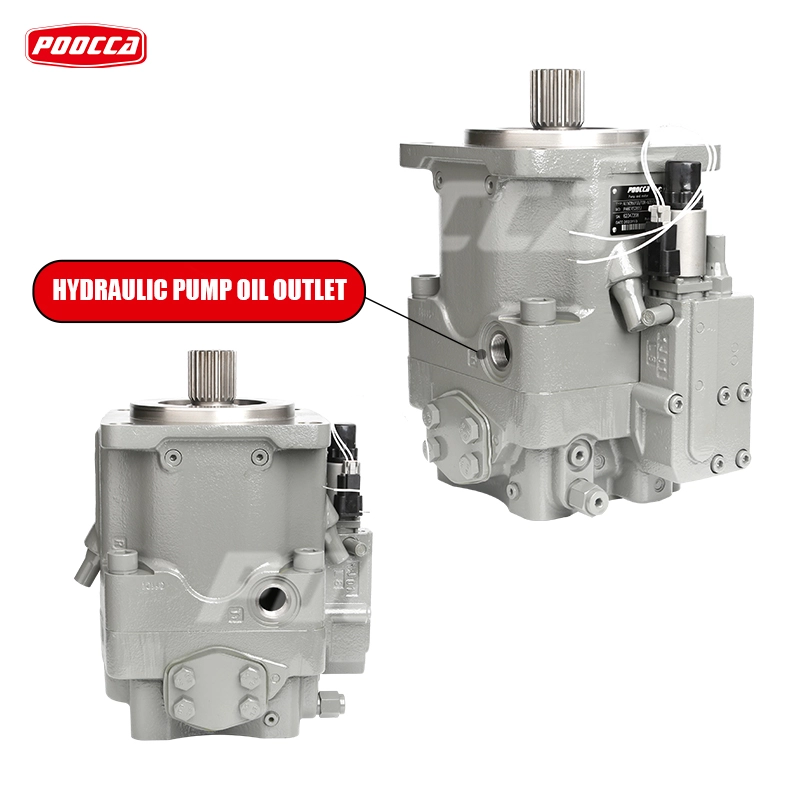

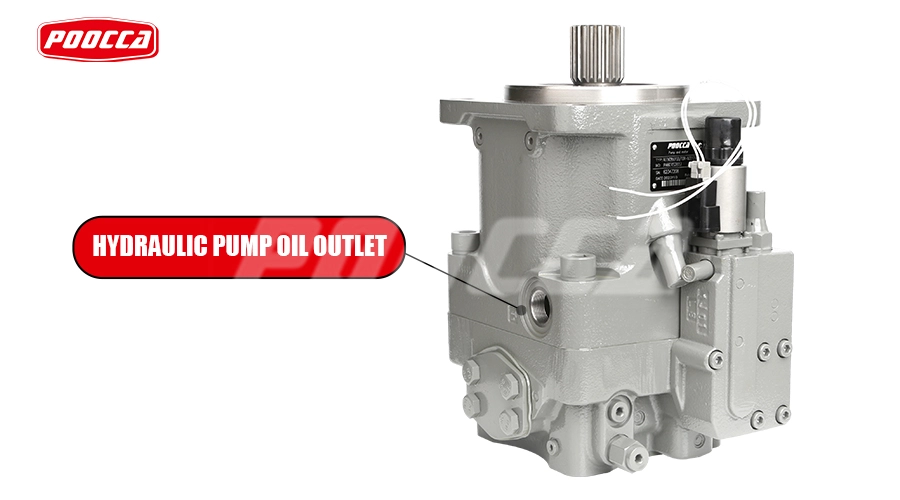

Key Components of Variable Displacement Piston Pumps

These pumps include several vital parts, each enhancing their effectiveness and flexibility.The pistons and cylinder block serve as the core, creating hydraulic pressure. The swashplate adjusts the pump’s displacement by altering the pistons’ movement angle. Control valves manage pressure and flow, ensuring consistency during use. The casing surrounds these elements, offering strength and shielding from external conditions. Together, these pieces allow the pump to adapt its output smoothly, making it perfect for tasks needing varied flow rates.

Applications of Variable Displacement Piston Pumps

Industrial and Mobile Hydraulic Systems

Variable displacement piston pumps find extensive use in both industrial and mobile hydraulic setups. In construction, they drive large equipment like excavators and cranes. They ensure accurate control and efficient energy use. Similarly, farming equipment, such as tractors and harvesters, gains from these pumps. They allow optimal hydraulic performance.

In manufacturing, dependable hydraulic systems power automated assembly lines and pressing machines. Variable displacement pumps enhance production by delivering steady pressure while cutting excess energy use.

Energy Efficiency in Modern Applications

Energy efficiency stands out as a key benefit of variable displacement piston pumps. Their ability to tweak flow according to need reduces power usage significantly. This makes them suitable for renewable energy systems. For instance, wind turbines employ these pumps in hydraulic pitch control setups. They adjust blades efficiently based on wind speed.

Hybrid vehicles also use these pumps to boost fuel economy. By refining hydraulic power distribution, they lower emissions and improve overall vehicle operation.

Emerging Innovations in Automation

Automation is reshaping hydraulic systems, and variable displacement piston pumps lead this change. With IoT and smart control integration, these pumps now support predictive maintenance. This reduces downtime and boosts dependability.

Real-time tracking lets engineers review performance data and adjust settings before problems emerge. This automation level lifts operational effectiveness and extends hydraulic system life. As technology advances, these pumps will remain central to automated industrial progress.

Variable vs. Fixed Displacement Pumps: Key Differences

Flexibility and Efficiency Advantages

Variable displacement piston pumps provide superior adaptability and energy efficiency over fixed displacement pumps. Fixed pumps run at a constant flow rate, often wasting energy when demand dips. On the other hand, variable pumps modify output as required. This cuts energy use and operating expenses.

Moreover, these pumps enhance system precision. They enable smoother performance in tasks needing diverse pressure and flow. This flexibility suits industries aiming to refine hydraulic efficiency without excess power consumption.

When to Choose Variable Displacement Over Fixed

Variable displacement piston pumps shine in situations demanding load-sensing features and variable speed functions. Systems facing shifting pressure needs benefit from their dynamic adjustments.

For instance, industrial presses, machine tools, and mobile hydraulic gear need exact control and energy savings. Here, variable displacement technology delivers efficiency without sacrificing capability. However, fixed displacement pumps suit simpler tasks with steady flow needs, like basic hydraulic lifting setups.

Maintenance Tips for Long-Term Performance

Common Issues and Troubleshooting

Like any hydraulic part, variable displacement piston pumps may face challenges over time. Typical troubles include leaks, worn pistons, and pressure swings. Leaks often stem from damaged seals or excessive wear. These require prompt replacement.

Pressure shifts might signal problems with control valves or hydraulic feedback systems. Regular checks catch these issues early, preventing breakdowns. Monitoring hydraulic fluid quality routinely is also vital. It helps avoid damage from contamination.

Best Practices for Extending Lifespan

For lasting performance, consistent upkeep is essential. Keeping hydraulic fluid pure and free of debris prevents early wear. Proper alignment of parts, like the swashplate and pistons, sustains peak efficiency.

Scheduled inspections spot potential issues before they escalate. Replacing worn components quickly extends the pump’s life, cutting downtime and repair costs. Following maker guidelines for lubrication and calibration further strengthens reliability.

Custom Solutions for Specialized Needs

Tailoring Pumps to Unique Applications

Various industries need bespoke hydraulic solutions for their distinct demands. Variable displacement piston pumps can be customized in materials, pressure ranges, and control setups.

POOCCA, a hydraulic industry pioneer since 2006, excels in crafting custom variable displacement piston pumps. Their skills span design, production, and upkeep of hydraulic parts. They ensure pumps meet exact operational needs. Whether for harsh settings, niche sectors, or cutting-edge automation, POOCCA delivers tailored options to boost hydraulic performance.

FAQs About Variable Displacement Piston Pumps

- How do variable displacement piston pumps improve energy efficiency?

By altering flow rates to match demand, they reduce energy waste and lower costs effectively. - What industries rely most on these pumps?

Sectors like construction, manufacturing, agriculture, and renewable energy depend on them heavily. - Can they replace fixed displacement pumps in existing systems?

Yes, in tasks needing variable flow and pressure control, they provide greater efficiency. - How often should maintenance be performed?

Routine checks and fluid reviews every few months ensure top performance. - What customization options are available for unique requirements?

Options include material choices, pressure tweaks, and smart control integration.

Innovating Hydraulics for Tomorrow’s Challenges

Variable displacement piston pumps are a cornerstone of hydraulic innovation. They help industries cut energy use and lift operational effectiveness. With progress in automation and digital tools, these pumps keep evolving. They meet the needs of modern sectors seamlessly.

Ready to refine your hydraulic systems? Check out POOCCA’s Variable Displacement Piston Pump Customization Services for solutions crafted to your needs. Contact POOCCA today or visit our site to see how innovation blends with dependability.