The Core Functionality of Vane Pumps

What is a Vane Pump?

A vane pump is a type of positive displacement pump. It utilizes vanes to transfer fluid from an inlet to an outlet. This engineering marvel operates by using a series of blades or vanes that are mounted to a rotor. These vanes slide in and out of grooves on the rotor, adjusting their position based on the fluid dynamics within the chamber. The clever design of the vane pump facilitates efficient fluid movement, which makes it ideal for a variety of applications across numerous industries.

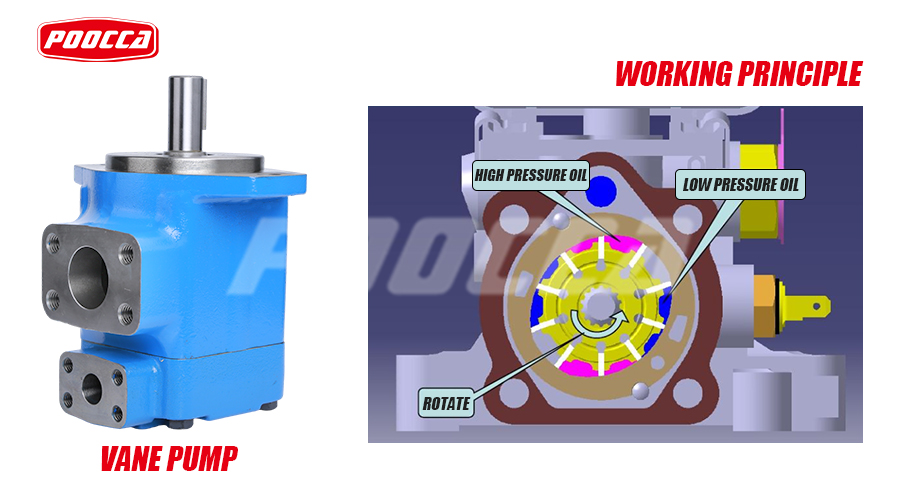

Basic Working Principle of Vane Pumps

The basic working principle of vane pumps is centered around the positive displacement mechanism. As the rotor turns, the vanes extend outward due to centrifugal force, creating a suction effect that draws in fluid through the inlet. The entrained liquid is then trapped within the spaces created between the vanes and the rotor. As the rotor continues to turn, the vanes move toward the outlet, reducing the volume of the trapped fluid and consequently increasing its pressure. This pressure difference allows for the efficient discharge of liquid through the outlet port, completing the pumping cycle.

Types of Vane Pumps and Their Applications

Classification Based on Pump Design

There are two types of vane pumps. Internal vane pumps. External vane pumps have vanes that stick out from the rotor and are ideal, for liquids, with viscosity as they can handle flow rates effectively. On the other hand, internal vane pumps have vanes that retract into the rotor to maintain precision and are better suited for handling liquids with viscosity levels. Both designs have their benefits. Serve different industrial requirements and standards.

Industry Applications

Businesses, and sectors, rely heavily upon vane pumps for their adaptability and effectiveness in settings such as hydraulic systems and automotive fuel systems, among others where accurate fluid delivery is crucially important. Moreover, vane pumps are also commonly found in HVAC systems and food processing facilities because of their capability to manage properties. The reliable performance of vane pumps secures their significance in evolving operations by addressing the complexities of engineering needs.

Advantages and Limitations of Using Vane Pumps

Benefits in Industrial Use

In industrial settings, vane pumps are well known for their benefits which include maintaining a flow rate when system pressure fluctuates. This helps keep operations running smoothly and efficiently. This feature makes vane pumps ideal, for tasks that demand delivery like, in chemical processing and hydraulic systems. Moreover, their compact design makes them easy to incorporate into machinery setups thus improving the effectiveness of equipment overall.

Additionally, vane pumps are known for their quieter operation in comparison to pump varieties. An aspect, in industrial environments where noise control is important Their versatility, also allows them to handle a range of fluids with varying viscosities making them suitable for industries Engineers and manufacturers prefer vane pumps due to their ability to work effectively with different types of fluids which makes them a popular choice, across various sectors.

Potential Drawbacks

Despite the benefits they provide vane pumps come with drawbacks that need to be taken into account when using them in environments. Their performance can suffer due, to their reliance on the rotor’s speed at rates resulting, in inefficiencies. This becomes crucial for applications that demand flow properties across operational scenarios.

Furthermore, vane pumps could be prone, to damage and deterioration because of their components especially when dealing with liquids. Due to the sliding motion of the vanes they might wear out quicker compared to fixed parts commonly seen in pump configurations. This leads to the need for upkeep and part replacements which could result in increased operational expenses over time. Lastly, vane pumps are typically not recommended for handling fluids, at temperatures as the vane materials may deteriorate under conditions thereby reducing their efficiency in such scenarios.

Best Practices for Optimum Performance

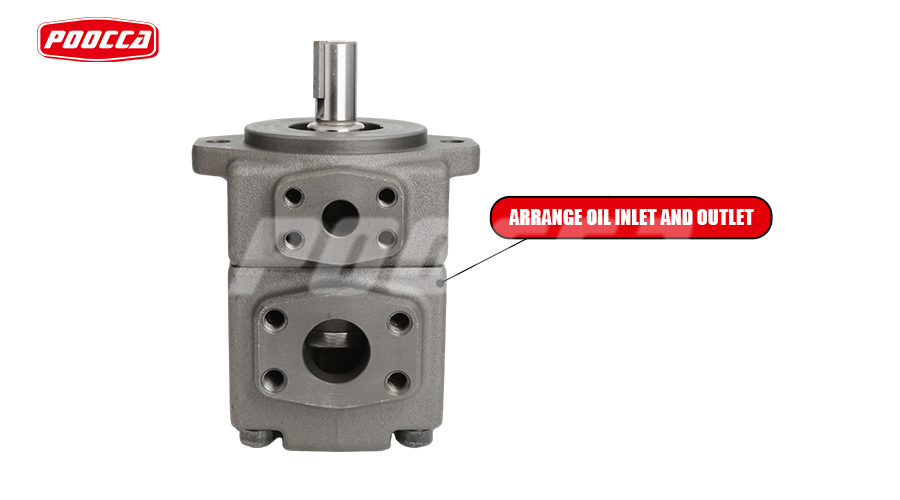

Installation Guidelines

It’s really important to get the installation right, for vane pumps to work at their level! Before setting it up you must make sure the pump is the size for what you’ll be using it for. Things, like how thick the fluid is and how fast you want it to flow matter a lot! Also don’t forget to line up the pump with the motor so it doesn’t strain and break down soon.

It is essential to conduct a thorough inspection of all connections and fittings for potential leaks and ensure proper sealing before connecting the pump to the piping system. This practice plays a crucial role in preserving efficiency and extending the lifespan of the pump. Adhering to the manufacturer’s guidelines regarding torque values and installation procedures is paramount in order to avoid any damage during setup. Consistent monitoring of the installation conditions and making any tweaks can greatly improve the performance and dependability of the vane pump.

Regular Maintenance Procedures

Proper upkeep is crucial, for keeping a vane pump running smoothly in the term. Take checks to look for wear and tear, on the vanes and inspect seals and gaskets for any signs of weariness. This is important because neglect to replace worn-out parts could result in decreased performance and potential leaks. This raises the chances of loss and operational inefficiencies.

Additionally keeping track of how the pump is working by checking its pressure and flow rate can help detect any issues at an early stage. Following a lubrication plan based on the manufacturer’s recommendations will ensure that the pump’s inner parts work properly and reduce friction that might cause damage. Moreover, maintaining cleanliness, in the vicinity of the pump is crucial to prevent substances from getting into the system and causing a decrease, in the effectiveness of the pump.

Troubleshooting Common Issues

Maintaining the performance of a vane pump involves troubleshooting issues that can affect its operation efficiency significantly. Some common problems to watch out for are fluctuations, in flow rates and strange noises coming from the pump as overpressure situations. For example, unstable flow rates could signal that the pump vanes are worn out or that there are blockages, in the inlet or outlet ports. Promptly dealing with these issues can help prevent them from escalating into problems that might result in repairs or replacements.

When you hear sounds coming from the machinery it’s important to check for cavitation or alignment problems right away! Cavitation can cause damage, in the run and misalignment can lead to more wear on the bearings and seals of the equipment. Moreover, if there’s pressure in the pump it’s a good idea to look into any potential blockages or backpressure, in the system that might be affecting performance. By referring to a troubleshooting manual you can significantly improve the durability and dependability of vane pumps.

POOCCA Products and Expertise in Vane Pumps

Overview of POOCCA’s Offering in Pump Technology

POOCCA is known for its cutting-edge pump technology products that include top-notch vane pumps tailored to meet standards effectively and reliably using state-of-the-art materials and creative designs to boost efficiency and dependability, in various industry settings with customized solutions for vascular pumps to optimize performance, across different operating conditions.

POOCCAs products are known for their lasting quality due, to the company’s dedication to research and development in pump technology and commitment to excellence in their offerings. Furthermore, POOCCA provides a range of support services such, as installation assistance, regular maintenance programs, and troubleshooting resources to ensure that their products maintain peak performance throughout their lifespan.

Why Choose POOCCA for Your Pump Needs?

By choosing POOCCA for your vane pump requirements you can count on tapping into expertise in pump technology and having a team of support at your disposal. The company’s established reputation, for dependability and customer contentment distinguishes it in the market. POOCCA blends cutting-edge technology and inventive ideas with a dedication, to customer service to provide clients with top-notch pumping solutions that are both effective and efficient.