Introduction to Hydraulic Piston Pumps

What is a Hydraulic Piston Pump?

A hydraulic piston pump is a hydraulic pump that utilizes pistons to create fluid pressure and flow. Typically found in hydraulic systems, these pumps rely on the reciprocating motion of pistons housed within a cylinder to displace hydraulic fluid, which is then directed through a system to perform work. The design and function of hydraulic piston pumps render them effective in converting mechanical energy into hydraulic energy efficiently, making them ideal for various applications. Their capacity to generate high pressures while maintaining reliability is what sets them apart from other types of pumps.

The Importance of Hydraulic Systems in Modern Machinery

Hydraulic systems are integral in modern machinery, providing the muscle behind numerous operations across different industries. They utilize fluid power to transmit force and motion, resulting in enhanced efficiency and control. From automotive applications and manufacturing processes to aerospace, the role of hydraulic systems cannot be understated. Hydraulic piston pumps, as key components of these systems, offer the reliability and performance necessary for critical operations.

Brief Overview of Poocca’s Expertise in Hydraulic Pumps

Poocca is recognized for its commitment to quality and innovation in hydraulic technology. With extensive experience in manufacturing and engineering hydraulic pumps, Poocca stands at the forefront of industry advancements. Their hydraulic piston pumps are designed to adhere to strict performance standards while accommodating diverse customer needs. With a focus on durability and efficiency, Poocca continually develops solutions that enhance productivity in hydraulic applications.

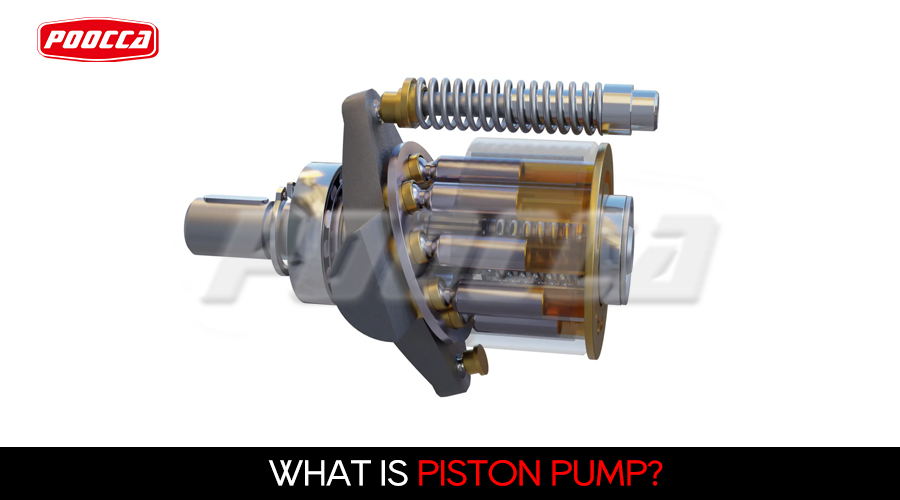

Fundamental Mechanics of Hydraulic Piston Pumps

Basic Components and Their Functions

A hydraulic piston pump consists of several essential components that work together to achieve fluid displacement.

Pistons

The pistons are the core of the hydraulic piston pump, moving within the cylinder block to create a vacuum that draws fluid in and forces it out. Their precise movement and fit are crucial for maintaining efficiency and preventing leakage, as they must create a tight seal against the cylinder walls.

Cylinder Block

The cylinder block houses the pistons and provides the structure necessary for the pump’s operation. It is designed to withstand high pressure and facilitate the movement of the pistons. The layout of the cylinder block can vary between axial and radial piston pumps, affecting the way hydraulic fluid is managed within the system.

Inlet and Outlet Ports

The inlet and outlet ports are critical for fluid entry and exit in the hydraulic piston pump. The inlet port allows hydraulic fluid to enter the system when the piston retracts, simultaneously creating negative pressure. When the piston moves forward, the outlet port expels the pressurized fluid into the hydraulic system, transferring power effectively.

The Working Principle: How Power is Transferred

The working principle of a hydraulic piston pump revolves around the reciprocating action of the pistons. As the driving mechanism rotates, it moves the pistons back and forth within the cylinder block. During the backward stroke, hydraulic fluid enters through the inlet port, filling the space created by the piston’s retraction. Upon the forward stroke, the fluid is compressed and forced out through the outlet port, thus transferring power to the connected hydraulic system. This back-and-forth motion effectively converts mechanical energy into hydraulic energy, making it a reliable source of power for various applications.

Types of Hydraulic Piston Pumps

Hydraulic piston pumps can be categorized into different types depending on their design and functionality.

Axial Piston Pumps

Axial piston pumps feature pistons arranged parallel to the drive shaft. This design allows for high efficiency and compact size, making them suitable for applications requiring variable displacement capabilities. They are commonly used in mobile machinery, such as forklifts and excavators.

Radial Piston Pumps

Radial piston pumps, in contrast, have pistons arranged around a central shaft. This configuration permits the pump to generate high pressures while providing robust performance characteristics. Radial piston pumps are typically employed in heavy-duty applications requiring reliable power and durability.

Advantages of Using Hydraulic Piston Pumps

Efficiency and Performance Benefits

Hydraulic piston pumps display excellent efficiency across various operating conditions. They can maintain consistent pressure and flow rates, even under heavy loads, significantly enhancing the performance of hydraulic systems. Their ability to generate high pressures with minimal energy loss contributes to overall operational efficiency.

Durability and Longevity

The robust construction of hydraulic piston pumps ensures durability and longevity. With high-quality components designed to withstand the stresses of hydraulic operations, these pumps are built to last. Regular maintenance can further extend their service life, making them a cost-effective choice for industries.

Versatility in Various Applications

Hydraulic piston pumps are adaptable and can be utilized in a myriad of applications. From industrial and construction machinery to automotive and aerospace sectors, their versatility allows them to effectively meet specific performance requirements across diverse fields. This adaptability makes them an ideal choice for businesses aiming to optimize their hydraulic systems.

Advantages Specific to Poocca’s Hydraulic Piston Pumps

Poocca’s hydraulic piston pumps come with a range of advantages that enhance their appeal. With a focus on innovation and quality, Poocca ensures that their products not only operate efficiently but also meet stringent safety and reliability standards. Customers benefit from tailored solutions that fulfill specific needs while ensuring optimal performance in their hydraulic applications.

Common Applications of Hydraulic Piston Pumps

Industrial Machinery

Hydraulic piston pumps are widely used in industrial machinery, powering systems like conveyor belts, presses, and other equipment requiring fluid power. Their ability to deliver consistent performance under varying loads makes them indispensable in manufacturing industries.

Construction Equipment

In the construction sector, hydraulic piston pumps are integral in equipment such as bulldozers, excavators, and cranes. These machines rely on the power generated by hydraulic systems to perform heavy lifting and grade materials effectively. Piston pumps facilitate the required force to ensure operational efficiency and productivity on construction sites.

Agricultural Machinery

The agricultural industry also depends heavily on hydraulic piston pumps for functions such as plowing, planting, and lifting. Tractors and other farming equipment utilize hydraulic systems to enhance functionality, allowing for greater efficiency in agricultural operations.

Specialized Uses (e.g., Aerospace, Marine)

Beyond the common applications, hydraulic piston pumps find specialized uses in fields such as aerospace and marine. In aerospace, they contribute to systems that require precise control and reliability under extreme conditions, while in marine applications, they assist in managing shipboard systems like steering and cargo handling. Their versatility and robust performance make them suitable for a wide range of unique operational demands.

Maintenance and Troubleshooting Tips for Optimal Performance

Regular Inspection Protocols

Regular maintenance is crucial for ensuring the optimal performance of hydraulic piston pumps. A structured inspection protocol can help identify potential issues early, preventing costly downtimes and repairs. It is advisable to schedule routine inspections at predetermined intervals, such as monthly or quarterly, depending on the operational context. During these inspections, key components of the hydraulic piston pump should be thoroughly examined to ensure they are functioning correctly.

Checking for Leakages

One of the primary concerns in maintaining hydraulic piston pumps is the occurrence of leakages. It’s essential to inspect all seals, connectors, and joints for possible leaks that could compromise the system’s integrity. Any signs of fluid accumulation or dampness around connections should be addressed immediately, as even small leaks can lead to significant fluid loss over time. Implementing a system of checks for leakage will ensure that the hydraulic system operates at peak efficiency and helps to minimize the environmental impact of lost hydraulic fluids.

Monitoring Oil Quality

The quality of hydraulic oil plays a vital role in the functionality of hydraulic piston pumps. Regular monitoring of the oil’s condition, including its viscosity, temperature, and color, can provide indicators of potential problems. Contaminated or degraded oil can lead to increased wear and tear on the pump components. Establishing a routine for oil analysis and timely replacement according to the manufacturer’s recommendations will not only prolong the lifespan of the pump but also optimize its performance.

Common Issues and How to Address Them

Hydraulic piston pumps can encounter various issues over time, but many common problems can be effectively addressed with appropriate techniques.

Noise Reduction Techniques

Excessive noise during operation can often indicate underlying issues within the hydraulic piston pump. Unusual sounds may stem from insufficient lubrication, cavitation, or the wear of components. To tackle these issues, it is essential to conduct an in-depth analysis of the system. Using vibration analysis and sound diagnostics, operators can pinpoint the source of the noise and take adjustments, such as recalibrating the pump or replacing worn parts. Furthermore, ensuring that pumps are installed correctly and isolated from other machinery can reduce noise levels significantly.

Minimizing Wear and Tear

Wear and tear in hydraulic piston pumps is an inevitable consequence of continuous operation but can be minimized through careful monitoring and management. Strategies include maintaining appropriate operating temperatures, using high-quality lubricants, and adhering to recommended maintenance schedules. Keeping the work environment clean and free from contaminants is equally essential, as debris can lead to component failure. Operators should also be educated on best practices for using hydraulic systems to ensure that pressures do not exceed recommended levels.

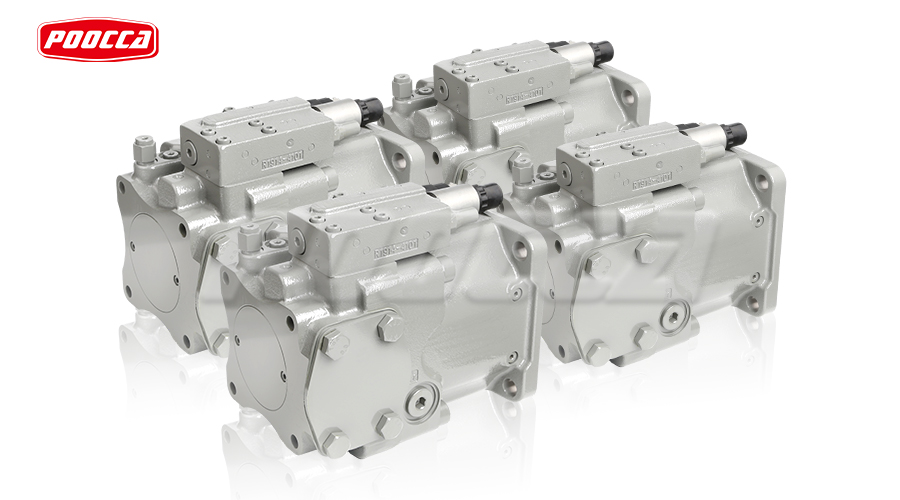

Why Choose Poocca for Your Hydraulic Solutions?

When it comes to hydraulic power solutions, Poocca is a reputable choice for businesses looking for efficiency and reliability.

Highlighting Poocca’s Industry-Leading Products

Poocca’s hydraulic piston pumps stand out in the market due to their commitment to quality and performance. With comprehensive research and development, their products are designed to meet the diverse needs of clients across various sectors. The combination of innovative engineering and rigorous testing ensures that Poocca’s products are well-equipped to handle demanding operational conditions.

Unique Selling Points of Poocca’s Hydraulic Piston Pumps

Poocca’s hydraulic piston pumps are engineered with precision, featuring advanced design elements that enhance their efficiency and reliability. Their customizable solutions cater to specific project requirements, allowing clients to maximize their operational capabilities. The incorporation of energy-efficient technology not only helps optimize performance but also reduces operational costs for users. Moreover, Poocca’s strong commitment to customer support ensures that businesses receive comprehensive assistance throughout the product lifecycle.

Customer Testimonials and Case Highlights

Users of Poocca’s hydraulic solutions consistently report significant improvements in performance and reliability. Case studies showcase successful implementations across various industries, highlighting the adaptability and effectiveness of their piston pumps. Clients often note enhanced efficiency and reduced downtime as notable benefits gained from utilizing Poocca products, showcasing the brand’s strong reputation in the field.

Comprehensive Support and Service Network

In addition to delivering high-performance products, Poocca boasts a robust support and service network, ensuring that customers have access to expert assistance whenever needed. Their dedicated team of professionals is available for consultations, troubleshooting, and maintenance support, providing peace of mind to users. With Poocca, businesses can trust that they have a reliable partner for their hydraulic solutions, supporting them every step of the way toward operational excellence.