What is a Gerotor Motor?

Gerotor motor technology has gained significant attention in various industries due to its efficiency and unique operational capabilities. A gerotor motor consists of a rotor and a stator, with the rotor having one less tooth than the stator. This design creates a chamber that expands and contracts, facilitating fluid movement and generating rotational motion. The simplicity of the gerotor mechanism allows for smooth and reliable performance, making it ideal for applications where consistent torque and low-speed operation are essential. Furthermore, gerotor motors are valued for their compact size, making them suitable for integration into systems with limited space. The versatility of these motors enables their use in diverse fields such as automotive engineering, industrial machinery, and hydraulic systems. Understanding the principles and advantages of gerotor motor technology can lead to innovative solutions in mechanical design and engineering projects.

Historical Background of Gerotor Motor Development

The development of the Gerotor motor dates back to the early 20th century, with significant contributions from mechanical engineers and inventors looking to create more efficient hydraulic systems. The intent was to develop a motor that could deliver consistent power output while minimizing mechanical complexities. Over decades, advancements in materials engineering and hydraulic fluid dynamics have driven the evolution of Gerotor motors, solidifying their place in modern engineering designs.

Detailed Working Principle of Gerotor Motors

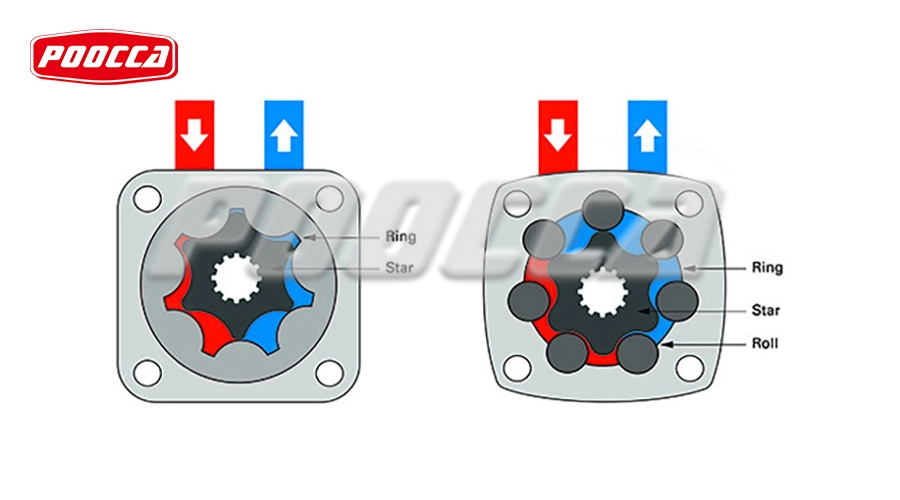

Inner and Outer Rotor Mechanism

At the heart of the Gerotor Motor, lies the interaction between the inner and outer rotors. The inner rotor is designed with one fewer tooth than the outer rotor, creating chambers that change volume as the rotors turn. As the hydraulic fluid enters these chambers, it pushes the rotors along defined paths, generating rotational motion. This fundamental mechanism is critical for the motor’s functionality and sets it apart from other types of hydraulic motors.

Interaction between the Inner and Outer Rotors

The process of interaction between the inner and outer rotors is meticulously engineered to guarantee the efficient transformation of hydraulic energy into mechanical energy. The teeth of the inner rotor align seamlessly with those of the outer rotor, preventing large gaps and promoting a smooth hydraulic fluid flow. Variations in the volume of chambers formed by the rotors directly influence fluid dynamics, which rotates the output shaft linked to the inner rotor, thereby producing torque.

Fluid Dynamics in Gerotor Motors

Role of Hydraulic Fluids

Hydraulic fluids serve as the lifeblood within Gerotor motors. These fluids, usually oils designed to withstand high pressures without compressing, flow through the motor’s chambers, driving the inner and outer rotor mechanism. Proper selection and maintenance of hydraulic fluid can significantly impact the performance and lifespan of the motor.

Pressure Changes and Flow Characteristics

Pressure changes within the motor are integral to its operation. As hydraulic fluid enters the expanding chambers between the rotors, it creates high-pressure zones that force the rotors to turn. Conversely, as the chambers reduce in size, the fluid exits, completing the cycle. This process ensures that the motor operates smoothly, with consistent torque and speed. The flow characteristics of the hydraulic fluid are also crucial; the fluid must maintain its viscosity and not degrade under operational stresses to ensure reliable motor performance.

Design Elements and Specifications of Gerotor Motors

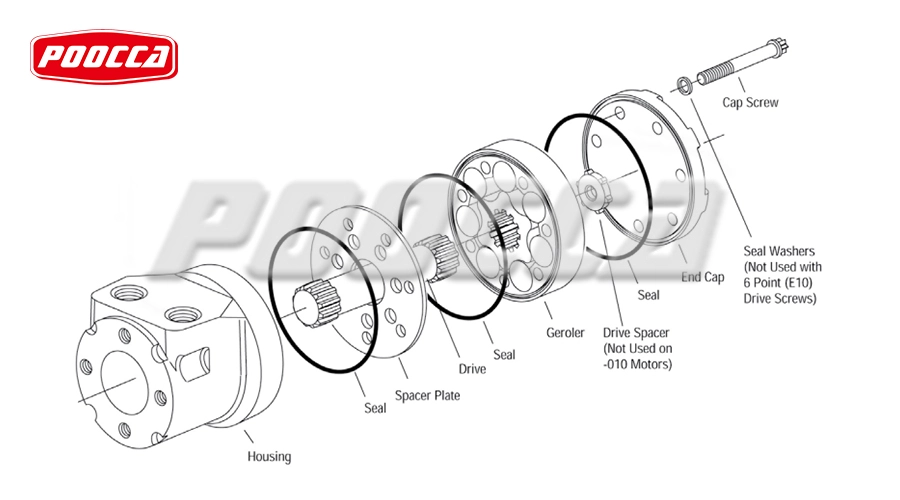

Key Components in a Gerotor Motor

The main components of a Gerotor motor include the inner rotor, outer rotor, casing, seals, and hydraulic fluid pathways. Each of these parts is engineered to high precision to ensure the motor operates as intended. The casing houses the rotors and fluid, providing structural integrity and protection.

Materials Used in Manufacturing

High-strength alloys and composite materials are frequently utilized in Gerotor motors to endure the mechanical stresses and recurrent hydraulic pressures they face. The selection of materials is vital to avert wear and tear, corrosion, and operational failures.

Precise Engineering Standards

Manufacturers adhere to precise engineering standards to maintain the reliability and efficiency of Gerotor motors. Every component is subjected to rigorous quality checks, and the assembly process is carefully controlled to avoid any deviations from the design specifications.

Typical Applications in Various Industries

Gerotor motors are versatile and can be found in a wide range of industries. In the automotive industry, they are used in power steering systems and fuel pumps. Industrial machinery often utilizes Gerotor motors for various hydraulic systems. They are also prevalent in agriculture, construction, and marine applications, where efficient and dependable hydraulic power is essential.

Advantages of Using Gerotor Motors for Engineers

Efficiency and Performance Benefits

A key advantage for engineers is the high efficiency offered by Gerotor motors. Due to their simple design and precise engineering, these motors can deliver superior performance with minimal energy loss. This efficiency translates into better fuel economy and lower operational costs.

Compact Design and Space Efficiency

Gerotor motors are notable for their compact design, making them perfect for scenarios where space is limited. Their minimal footprint enables engineers to incorporate robust hydraulic systems into tight spaces without sacrificing performance.

Low Noise and Smooth Operation

Another significant benefit is the low noise and smooth operation of Gerotor motors. This makes them suitable for applications where noise reduction is crucial, such as medical equipment or residential machinery. The smooth operation also contributes to longer operational life and reduced maintenance requirements.

By understanding the Gerotor Motor Working Principle and Advantages, engineers can better appreciate the technology and its applicability across various domains. Institutions like POOCCA have taken these principles and refined them further, offering state-of-the-art solutions that embody the efficiency, compactness, and reliability that the Gerotor motor promises.

Comparison with Other Hydraulic Motors

Differences in Working Principles

When comparing Gerotor motors to other types of hydraulic motors, such as vane or piston motors, the Gerotor Motor Working Principle and Advantages become evident. Gerotor motors utilize a simpler rotor mechanism comprising an inner and outer rotor, which changes the chamber volumes and drives hydraulic fluid. In contrast, vane motors employ sliding vane mechanisms, and piston motors use reciprocating pistons, each resulting in distinct motion generation methods. This fundamental difference in working principles directly impacts their operational characteristics and suitability for various applications.

Performance Metrics: Energy Efficiency, Durability, Maintenance

Evaluating the performance metrics highlights why engineers frequently choose Gerotor motors. Regarding energy efficiency, Gerotor motors generally exhibit reduced energy loss thanks to their simpler mechanical design, which results in improved fuel economy and lower operational costs. Durability is another notable benefit; their robust construction and fewer moving parts lead to decreased wear and tear over time. Maintenance needs for Gerotor motors are typically minimal when compared to other hydraulic motors, as their design naturally minimizes potential points of failure. This contributes to longer operational lifespans and less frequent servicing.

Real-World Applications and Case Studies

Utilization in Industrial Equipment

In the realm of industrial equipment, the Gerotor Motor Working Principle and Advantages are particularly beneficial. These motors are frequently deployed in machinery used for heavy-duty tasks such as conveyor systems, metal forming machines, and automated production lines. Their reliable performance and ability to deliver consistent torque make them ideal for demanding industrial environments. Case studies have shown that companies incorporating Gerotor motors into their equipment experience reduced downtime and enhanced productivity due to their low maintenance and high reliability.

Application in Automotive Systems

Gerotor motors also play a pivotal role in automotive systems. They are commonly used in auxiliary systems like power steering, fuel transfer, and precise vehicular hydraulic applications. In these scenarios, the compact design and smooth operation of Gerotor motors are crucial. Engineers designing modern vehicles prioritize space efficiency and low noise, areas where Gerotor motors excel. Furthermore, the continued advancements in automotive engineering have seen these motors adapted for newer, more energy-efficient vehicles, highlighting their versatility and continued relevance.

Introducing POOCCA

About POOCCA and Its Offerings

POOCCA stands out as a forward-thinking company in the hydraulic motor industry, building on the innovative foundations of Gerotor motor technology. Poocca motor manufacturer, with 20+ years of hydraulic experience, can provide orbital motors of brands such as Parker, Danfoss, Eaton, etc., series are TG TC TF orbital motors, OMP OMH OMS hydraulic motors, 2000 series 4000 series 6000 series 10000 series cycloidal motors.

In addition to selling orbital motors, there are also gear motors, piston motors, and vane motors. Our extensive catalog includes various hydraulic solutions tailored to meet diverse engineering demands. By integrating advanced materials and precision engineering, POOCCA ensures that our products deliver optimal performance and reliability.

Special Features of POOCCA’s Gerotor Motors

POOCCA’s Gerotor motors feature unique characteristics that bring substantial benefits to engineers. Constructed from high-strength alloys, these motors are designed for enhanced durability and wear resistance. The rotors are precision-manufactured, ensuring smooth fluid dynamics, which contributes to overall energy efficiency and quiet operation. Additionally, POOCCA offers customized solutions, enabling tailored designs to meet specific application requirements. This flexibility is particularly advantageous for engineers seeking bespoke hydraulic solutions.

Understanding the Gerotor Motor Working Principle and Advantages within the context of POOCCA‘s offerings highlights how this technology can be optimized for even the most demanding applications. By leveraging the strengths of Gerotor motors, POOCCA sets a benchmark for innovation and reliability in the hydraulic motor industry.

If you have any needs, please contact us, we will provide you with parameter information, specific information of the size diagram, and look forward to cooperating with you.