Noise reduction is becoming increasingly critical in many hydraulic-system-containing industries. Besides being an operational nuisance, it is a serious health and safety issue. Amongst the growing demand for quieter solutions, hydraulic vane pumps have become a cornerstone technology. They offer an unbeatable mix of low-noise performance, efficiency, and adaptability, finding a place in many noise-sensitive applications.

Hydraulic Vane Pumps: The Mechanics Behind the Silence

How Do Hydraulic Vane Pumps Work?

A hydraulic vane pump consists of a rotor with sliding vanes inside a cavity. The rotation of the rotor causes the vanes to slide outwards, creating sealed chambers. These sealed chambers suck hydraulic fluid from the inlet and push it through the outlet with pressure. The smooth movement of the vanes allows for a continuous flow with minimal pulsation, which is a main factor in noise reduction.

Key design features that contribute to their quiet operation include:

- Smooth Rotor Motion: The sliding vanes produce less turbulence and vibration compared to other pump designs.

- Efficient Sealing: High-precision sealing minimizes fluid leakage and pressure fluctuations, both of which can cause noise.

- Optimized Material Choices: Advanced materials with excellent wear resistance and vibration dampening properties reduce operational noise further.

Why Noise Reduction Matters in Hydraulic Systems

The Impact of Noise on Operations

In industrial settings, excessive noise is more than an annoyance; it has tangible consequences:

- Worker Health: Continuous exposure to high noise levels can lead to hearing loss and increased stress.

- Regulatory Compliance: Noise pollution regulations are tightening across industries, particularly in urban and residential areas.

- Operational Efficiency: Loud environments can distract workers, leading to decreased productivity and increased errors.

By implementing low-noise technologies, such as hydraulic vane pumps, these industries can meet these issues and, at the same time, improve their overall efficiency.

Applications That Demand Low-Noise Hydraulic Vane Pumps

1. Automotive Industry

Hydraulic vane pumps have very wide applications in automotive systems, starting from power steering and braking systems. For such applications, low noise improves the driving experience by guaranteeing reliability of performance.

2. Aerospace

Hydraulic systems in aircraft handle flight surfaces, landing gear, and braking systems. Quiet pumps reduce noise pollution in the cabin to provide better passenger comfort.

3. Manufacturing and Precision Tools

Hydraulic power is utilized in CNC machines, injection molding systems, and robotics. Low-noise pumps ensure smooth operation, enabling precise outcomes while maintaining a comfortable workspace.

4. Healthcare and Laboratories

Medical devices and laboratory equipment frequently operate in noise-sensitive environments. Hydraulic vane pumps provide quiet, reliable power for tools like patient lifts and diagnostic machinery.

5. Residential and Commercial Applications

The hydraulic pumps reduce the noise for applications like elevators, escalators, and HVAC in highly populated places.

How Hydraulic Vane Pumps Excel in Noise Reduction

1. Reduced Pulsation

The majority of noise emanates from hydraulic systems that depict a pulsation problem. A vane pump features a continuous fluid flow that erases pulsation problems, offering quiet operation without bumps and jerks.

2. Low Vibration Levels

Vane pumps are designed with high mechanical balancing to minimize vibrations. The effects of this feature include less noise and the potential for reducing damage to the pump and any attached equipment due to vibration.

3. Pressure-Compensated Designs

Most vane pumps incorporate pressure-compensating devices that automatically adjust output to system demand, thus enabling a consistent level of performance without the noisy surges so common with uncompensated pumps.

4. Intelligent Control Systems

Modern vane pumps contain integrated smart controls and monitoring systems. These systems optimize pump performance in real time, reducing operational stress and noise output.

Hydraulic Vane Pumps vs. Other Pump Types

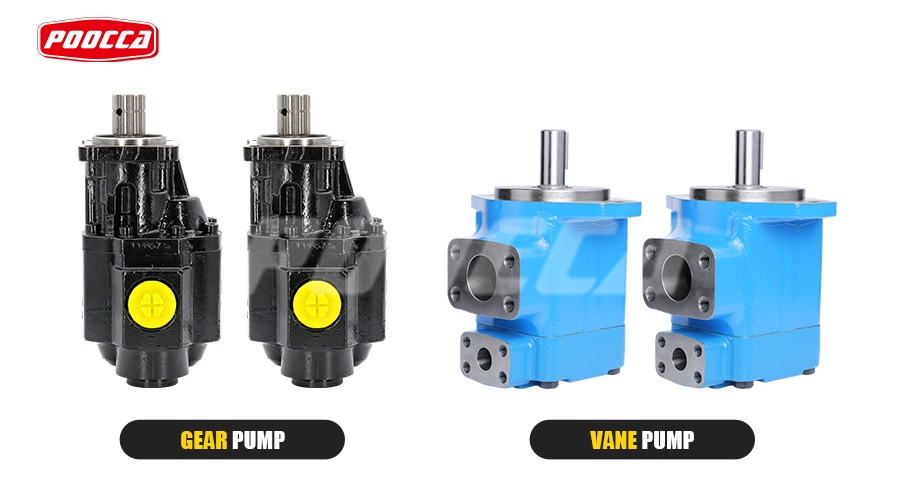

Vane Pumps vs. Gear Pumps

Gear pumps are strong and inexpensive but inherently noisy because of the design that has constant metal-to-metal contact. For those applications where noise sensitivity is required, vane pumps will be preferred due to their smoothness in operation.

Vane Pumps vs. Piston Pumps

Piston pumps are suitable for high-pressure applications but often result in considerable noise due to their complicated mechanisms. Vane pumps, on the other hand, are ideal for medium-pressure systems that focus on noise reduction.

The Role of Maintenance in Noise Reduction

Even the quietest hydraulic vane pumps can become noisy if not properly maintained. Factors contributing to noise include:

- Worn Components: Over time, vanes, seals, and bearings can degrade, leading to increased friction and noise.

- Incorrect Lubrication:The least lubrication will create greater friction and mechanical wear.

- Fluid Contamination:Dirt and debris in hydraulic fluid cause cavitation, one of the main sources of noise.

Maintenance Tips for Prolonged Quiet Operation

Regular Inspections: Check for signs of wear, leaks, or damage.

Fluid Quality Management: Only use high-quality hydraulic fluid and change it at the right time.

Seal and Fastener Checks: All the seals are well-placed and the fasteners are securely tightened to prevent leakage and vibrations.

Cleaning Periodically: Particles and other contaminants should be cleaned off in order to prevent blockage or cavitation.

Poocca Hydraulic Vane Pumps: Redefining Quiet Performance

Since 2006, Poocca Hydraulics has always risen to the top with unparalleled solutions in hydraulics. The company manufactures a gamut of vane pumps ranging from research and development, manufacture to maintenance of hydraulic parts for applications requiring low-noise operation.

Poocca’s Hydraulic Vane Pump Offerings

Single-Acting Vane Pumps: For applications of low pressure, these kinds of pumps are best suited when efficiency and simplicity are solely sought after by the systems.

Double-Acting Vane Pumps: Ideal for applications that involve high pressure, these vane pumps will grant excellent performance without compromising on noise reduction.

Variable Vane Pumps: Having variable displacement, the pump will be capable of controlling applications that demand customization in flow.

What Makes Poocca Vane Pumps Stand Out?

Quiet Operation: Advanced designs ensure minimal noise, even under heavy loads.

High Efficiency and Stability: Poocca vane pumps maintain excellent performance within a very wide pressure range.

Durability: Constructed of high-strength material, the pumps have withstood hard working conditions.

Ease of Maintenance: Because designs are simpler, cleaning, inspection, and other forms of repairs are rather uncomplicated.

Advanced Technologies: Smart systems are able to auto-adjust to changing conditions in real-time, while advanced monitoring works to extend pump performance life.

Tailored Solutions for Every Industry

Currently, Poocca represents several brands and models but is not limited to the following:

- Parker Vane Pumps: T6, T7, and PV2R series.

- Yuken Vane Pumps: PV2R series.

- Vickers Vane Pumps: V and VQ series.

Besides the representation of various renowned brands, the company also provides for customization to meet specific operational requirements to ensure that the client receives a solution that meets their needs.

Conclusion: Quiet Power for a Better Future

The hydraulic vane pump represents one of the huge leaps taken in noise reduction and operational efficiency. Minimizing noise pollution, these pumps comply with modern regulations and provide healthier and more productive work environments.

When it comes to hydraulic solutions of low noise, Poocca is a name industries trust. With decades of expertise, a diverse product range, and a commitment to quality, Poocca Hydraulics is at the forefront of the quiet revolution.

For reliable, efficient, and silent hydraulic power, reach out today to Poocca and see the change it brings in your operations.