Hydraulic systems form the backbone of numerous industrial applications; the pumps driving these systems determine their efficiency and effectiveness. Out of the different types of hydraulic pumps, the variable displacement piston pumps have grown in popularity because they can adjust their flow rate to demand conditions. This attribute makes them pretty versatile and rather at an advantageous position compared with fixed displacement pumps, hence the favorable choice for modern hydraulic systems.

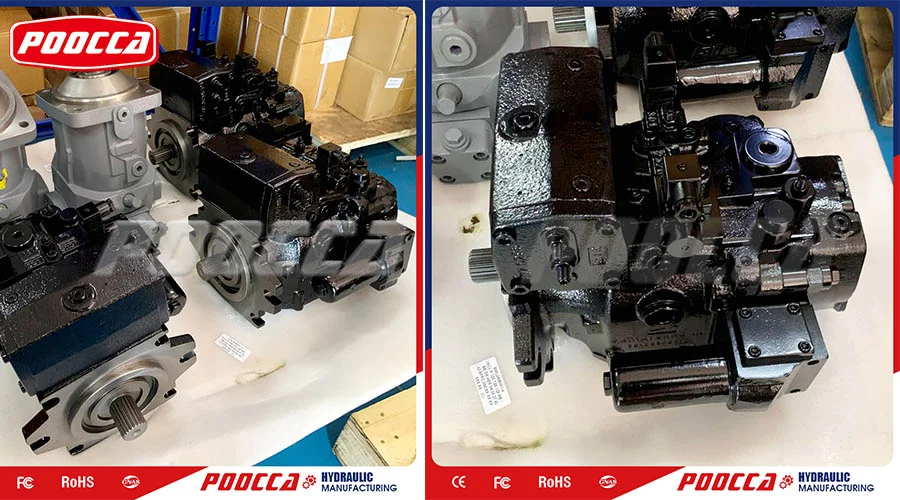

The advantages of variable displacement piston pumps lie in how well they enhance functionality and efficiency in hydraulic systems. In this blog, POOCCA will look at some key advantages of variable displacement piston pumps. The company provides a variety of hydraulic pumps for the best performance and reliability, including variable displacement piston pumps.

What Makes Variable Displacement Piston Pumps Different?

How Does a Variable Displacement Piston Pump Work?

Unlike the fixed displacement pumps, which supply a constant flow rate irrespective of the system’s demands, the variable displacement piston pumps have their volume of discharge fluid per revolution changeable. This is mostly done through mechanisms that vary the stroke of either the pistons or the swashplate angle. Changing the length of stroke of the pistons alters the volume of fluid displaced in every cycle.

Another common design approach is to have an angled surface against which the pistons reciprocate, and the angle of the swashplate changes the effective stroke length of the piston to vary the output flow from the pump. POOCCA’s variable displacement piston pumps have been designed in precision to offer smooth and efficient flow adjustment.

What are the Design Types of Variable Displacement Piston Pumps?

Designs also include variable displacement piston pumps: axial, radial, and finally bent axis configuration. Each type has unique advantage in terms of compactness, efficiency, flow characteristics, or any combination among these factors. Axial piston pumps contain parallel pistons that move to and from the pump axis. Their counterpart, on the other hand, the radial piston pumps contain pistons lying radially with a common axis. In addition, pistons of a bent axis design are set at an angle relative to the drive shaft. POOCCA offers varied models to be able to find an appropriate type of pump in line with each application.

Key Benefits of Variable Displacement Piston Pumps

Improved Efficiency by Controlling Flow

In fact, among the main reasons why variable displacement piston pumps enjoy a lot of popularity is its efficiency in providing energy. Their flow rate would adjust according to the system it serves, consuming less energy with less waste. That is unlike the fixed displacement pumps, which have a constant flow rate despite the system requirements; hence, energy is wasted. Variable displacement pumps-like the Rexroth A10VSO series that is also in POOCCA’s portfolio-save operating costs by adjusting output, thus reducing environmental impact.

Improved System Performance and Responsiveness

Variable displacement pumps have some advantages in their effectiveness for system performance and responsiveness. These pumps grant hydraulic systems more precision and speed since they supply only the amount of hydraulic fluid actually required at any given time. This is crucial in applications that demand high accuracy, such as in manufacturing and aerospace. POOCCA’s hydraulic piston pumps boast excellent fluid control, hence enabling smooth and reliable operation.

Longer Operating Life and Lower Maintenance

Another positive aspect of the variable displacement piston pumps is the longer usable life, along with lesser maintenance needs. They work at a far lower power input and regulate their flow rates to match demand; hence, they wear out much less than fixed displacement pumps. In turn, this means fewer maintenance activities and a longer life span before replacement, reducing chances of stoppage and extra costs. POOCCA stands by the durable life of its pumps by fabricating them from quality materials.

Why Choose Variable Displacement Piston Pumps?

Industry Versatility and Adaptability

Variable displacement piston pumps are adaptable to very good factors; thus, versatile enough for quite a wide range of industrial purposes. The pump is widely used in the construction and manufacturing industries, among many others, going all the way up to the aerospace industry, in which they adapt to conditions easily. Be it the circulating of drilling mud in the oil and gas industries or for the purpose of accurate control in the chemical and pharmaceutical field, Variable Displacement Piston Pumps play a huge role. In this regard, POOCCA‘s variable displacement piston pumps exist in several model variations targeted toward the specific usage of different sectors.

Cost Saving with Sustainability

The time will tell about the variable displacement piston pumps, saving one thousand dollars sooner or later with the energy efficiency and reduced maintenance of these types. Sustainability in operation is ensured with minimum energy use and waste production by these pumps. Hence, industrial operators can achieve better productivity with a low carbon footprint by choosing such pumps. POOCCA stands concerned about offering energy-efficient solutions that are appropriate for modern sustainability goals.

Making the Right Choice: Choosing a Variable Displacement Piston Pump

Things to Consider for Your Hydraulic System

You will have to select a variable displacement piston pump while minding the needs of your hydraulic system. Included in these are rating of pressure required, flow rate, and the type of fluid to be used. Also, the design type of the pump – axial, radial, or bent axis – has to be factored in for an exact application fit. POOCCA has different types of displacements and mounting flanges to help customers find the most suitable hydraulic products for their systems.

Routine Maintenance and Performance Testing

Hydraulic variable displacement piston pumps have to be maintained regularly and tested for performance so they can continue working at optimal conditions. The routine maintenance entails periodic activities that may include lubrication, the changing of seals, and examination of gears, amongst other pump components. Regular performance testing will include the testing of the pump’s efficiency and output, with comparison to the original specifications of the pump, which can highlight any degradation in performance. The POOCCA pumps can give extended service life and reliable operation with regular maintenance.

Variable displacement piston pumps are the backbone of any modern hydraulic system, promising energy efficiency, high performance, and long life. Understanding their advantages and carefully selecting the right pump can lead to an optimum hydraulic system for any given industrial application. Versatility and reliability make the pumps a must for industries striving toward efficiency and sustainability.