Piston pumps, as an important fluid transfer equipment, play an indispensable role in the petrochemical industry. As an important pillar of the national economy, the petrochemical industry involves a wide variety of fluid media in its production process, which requires extremely high performance of the pump. Piston pump because of its unique structure and working principle, in the petrochemical industry has a wide range of application scenarios, but also faces many challenges.

Special application of piston pumps in the petrochemical industry

The working principle of the piston pump is simple and effective, through the reciprocating motion of the piston in the pump cylinder, change the volume of the pump cylinder, so as to realize the liquid suction and discharge. This pump type has a wide range of applications in the petrochemical industry:

High viscosity media transportation

Petrochemical industry, often need to deal with high viscosity, high solid content of the media, such as heavy oil, asphalt and so on. Piston pumps because of its ability to generate high pressure and flow, and the viscosity of the medium is not sensitive to changes in viscosity, become the ideal choice for conveying such media.

High-temperature and high-pressure environment applications

Petrochemical production process, many processes need to be carried out in high temperature and high pressure conditions. Piston pumps have a compact structure and good sealing. Therefore, it can withstand higher temperatures and pressures. By selecting materials and seals that are resistant to high temperatures and pressures, piston pumps are able to operate stably in harsh operating environments.

Corrosive media handling

In the petrochemical industry, the treatment of corrosive media is an important link. Piston pumps are made of corrosion-resistant materials, such as stainless steel, special alloys, etc., which can resist the erosion of corrosive substances such as acids, alkalis and salts in the medium. At the same time, through the reasonable flow channel design and sealing structure, the contact area between the medium and the pump body material is reduced, which further prolongs the service life of the pump.

Accurate measurement and control

In the petrochemical production process, accurate fluid metering and control is crucial. Piston pumps are able to achieve more accurate flow control due to their reciprocating motion. By adjusting the stroke and frequency of the piston, precise adjustment of the flow rate can be realized. In addition, combined with modern control technology, such as PLC, frequency converter, etc., can realize the remote monitoring and intelligent control of the piston pump, improve the automation level of the production process.

Challenges faced by the piston pump in the petrochemical industry

Although the piston pump in the petrochemical industry has a wide range of applications, but in the actual application of the process also faces many challenges:

Medium adaptability problems

Petrochemical industry in a wide variety of media, different media on the pump material, sealing performance and other requirements are different. Piston pumps in response to different media, you need to take into account the corrosiveness of the medium, viscosity, abrasiveness and other factors, select the appropriate material and structure. However, due to the complexity and variability of the medium, the adaptability of the medium of the piston pump has become an urgent problem.

High reliability requirements

The continuity and stability of the petrochemical production process is crucial, once the pump fails, it will probably lead to the shutdown of the whole production line. Therefore, the high reliability requirements of piston pumps have become an important challenge. To improve the reliability of piston pumps, we need to start from the design, manufacturing, installation, maintenance and other aspects to ensure that the pumps can operate stably under various working conditions.

Energy saving needs

With the growing awareness of environmental protection, the petrochemical industry is increasingly demanding energy saving and consumption reduction. Piston pumps in the operation process will produce a certain amount of energy consumption, how to reduce energy consumption, improve energy efficiency has become an urgent problem. By optimizing the structural design of the pump, improving the efficiency of the pump and adopting advanced control technology, the energy consumption of the piston pump can be effectively reduced to achieve the goal of energy saving and consumption reduction.

Maintenance and repair complexity

Piston pumps as a more complex fluid transportation equipment, its maintenance and repair work is relatively cumbersome. In the petrochemical industry, due to the harsh production environment and the specificity of the medium, the maintenance and repair work of the piston pump is more challenging. How to simplify the maintenance process, improve maintenance efficiency, reduce maintenance costs, piston pumps in the petrochemical industry has become an important issue to face.

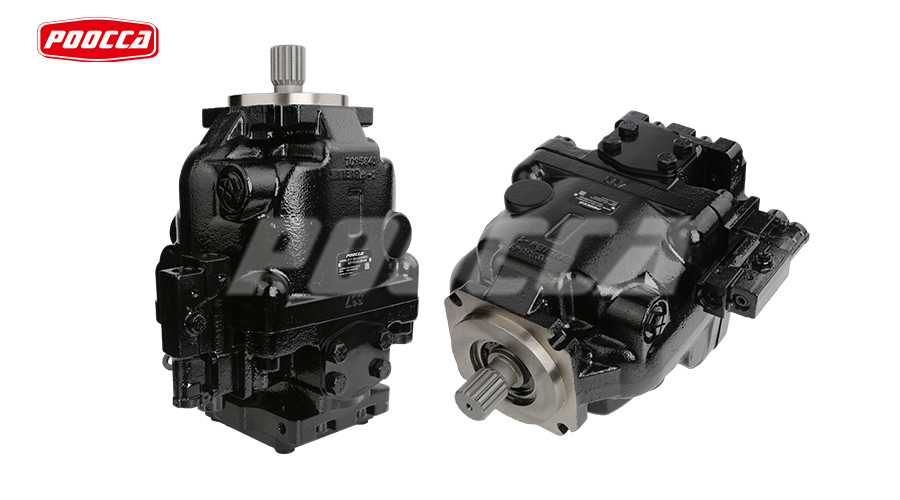

POOCCA is a leading brand in the hydraulic industry. The piston pump product is POOCCA’s long-term best-selling product. All our products have been tested many times. POOCCA products can only leave the factory after passing the test. POOCCA products will almost never have quality problems such as cracking of the pump body. If you concern about the quality of piston pumps, POOCCA should be your first choice.

In conclusion, piston pumps boast a broad spectrum of applications within the petrochemical industry, yet they are not without their share of challenges. To harness the full potential of piston pumps in this sector, there is a pressing need to persistently enhance their performance, bolster reliability and escalate energy efficiency. This should be coupled with streamlining maintenance procedures and curbing associated expenses.