What is a Single Vane Pump?

A single vane pump is a kind of hydraulic pump that employs a spinning mechanism to shift liquid smoothly. It functions by using several blades that glide in and out of a central rotor. This creates spaces that grow and shrink to move fluid effectively. People use it widely across many fields because it is dependable, small in size, and runs quietly.

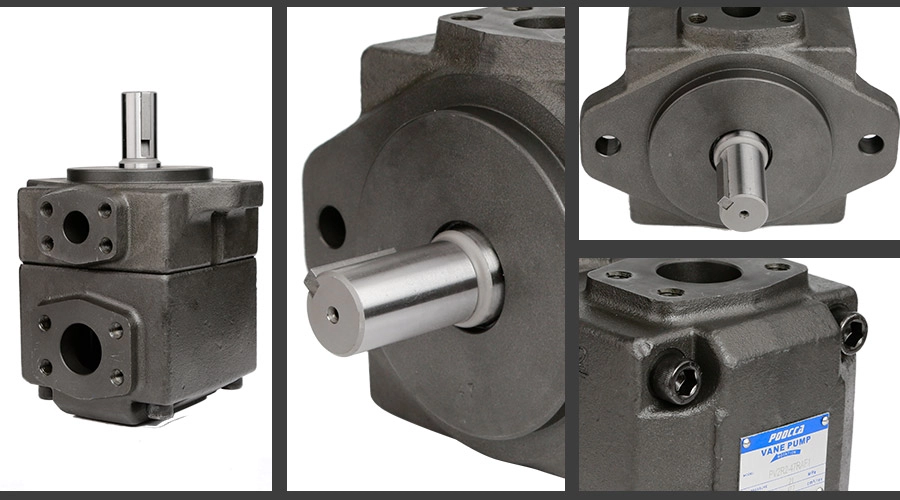

Core Components and Design

A single vane pump includes various vital parts that collaborate to ensure fluid moves effortlessly. These parts are the rotor, blades, cam ring, and casing. The rotor serves as the main spinning element inside the casing. Blades are tiny, flat pieces that slide within slots in the rotor. They stretch out and pull back as the rotor spins, staying in touch with the cam ring. The cam ring is a steady piece that supports the blades’ motion. Meanwhile, the casing surrounds everything and directs the liquid properly through the setup.

Working Principle of Hydraulic Single Vane Pumps

The way a single vane pump operates relies on moving liquid via spinning force and blade action. When the rotor turns, this force thrusts the blades outward. Consequently, they maintain steady contact with the cam ring. This process forms sealed spaces that change in volume as the rotor moves. When these spaces widen, they produce a suction effect that pulls in liquid. Then, as the rotor keeps spinning, the spaces narrow. This pushes the liquid out through the exit point. This ongoing cycle keeps a constant stream of hydraulic fluid flowing. Thus, it performs highly effectively in industrial tasks.

Key Advantages of Single Vane Pump Technology

Single vane pumps provide numerous benefits compared to other types, like gear or piston pumps. Their structure suits tasks needing steady and even liquid movement perfectly.

Compact Design for Space-Constrained Applications

One major perk of single vane pumps is their petite and light build. Their modest size fits well in setups with little room, such as in cars or aircraft. The straightforward inner design allows simple blending into current systems. No major changes are needed. Plus, their adaptability makes them useful in both fixed and portable hydraulic setups.

Energy Efficiency and Low Noise Operation

Single vane pumps stand out for their power-saving nature compared to rival pump styles. The blades’ fluid motion cuts energy waste, leading to reduced power use. This perk shines in tasks where lowering running costs matters greatly. Another plus is their quiet performance. Unlike gear pumps, which get loud from metal clashing, single vane pumps run with little shaking. This makes them perfect for places where keeping noise low is crucial.

Longevity in Demanding Environments

Sturdiness is another key strength of single vane pumps. They feature tough materials that resist wear, cutting down on inner rubbing. This leads to a prolonged working life. The self-adjusting blades adapt to wear over time, keeping output steady even after long use. These pumps endure high forces and work well in tough settings. Hence, they suit industrial, automotive, and power-related tasks admirably.

Industrial Applications of Single Vane Hydraulic Pumps

Single vane pumps see broad use across diverse sectors due to their effectiveness and trustworthiness. Their knack for managing various liquids makes them vital for many hydraulic systems.

Automotive and EV Cooling Systems

In the car industry, single vane pumps are key for cooling and oiling systems. They help in electric vehicle (EV) battery heat control setups, keeping batteries at ideal temperatures for top output. These pumps also play a role in oiling systems for regular engines. There, they circulate oil smoothly to lessen rubbing and wear.

Renewable Energy Systems

The green energy field gains from single vane pumps in several ways. In wind power, they assist hydraulic blade angle systems. These adjust turbine blades for peak efficiency. In solar setups, they aid liquid movement for heat swapping. Their ability to handle shifting temperatures and forces makes them a smart pick for eco-friendly energy uses.

Food Processing and Pharmaceutical Machinery

Clean liquid handling is a must in food and drug industries. Single vane pumps excel here because they manage delicate liquids with little risk of tainting. Many makers use rust-proof materials, like stainless steel, to meet cleanliness rules. These pumps also deliver steady, smooth liquid flow. This is critical for exact dosing and blending tasks.

Choosing a Reliable China Single Vane Pump Factory

When picking a single vane pump supplier, consider factors like production skills, tailoring options, and quality levels carefully.

OEM vs. ODM Single Vane Pump Manufacturers

Two main maker types exist: OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer). OEM makers craft pumps to a client’s exact needs, giving custom answers for special uses. Meanwhile, ODM makers offer ready-made pumps needing few tweaks. Knowing these differences helps firms pick the right supplier for their goals.

Quality Assurance in Wholesale Single Vane Pump Factories

Quality checks matter greatly when sourcing single vane pumps from China. Trustworthy makers stick to tight control steps and hold marks like ISO and CE. These marks show the pumps meet field standards for output and safety. Tests for pressure strength and efficiency further ensure the pumps work well in real tasks.

The Role of POOCCA Customization Services

POOCCA delivers custom hydraulic answers for unique needs, blending fast model-making with global standards. Their ready-to-ship single and double vane pumps promise quick delivery without skimping on Parker-Yuken-level output. With a keen focus on tailoring, POOCCA aids firms seeking top-notch hydraulic pumps for specific tasks.

Maintenance Tips for Single Vane Hydraulic Pumps

Good upkeep is crucial to keep single vane pumps lasting long and working well. Regular checks and preventive steps can dodge pricey fixes and downtime.

Preventing Vane Wear and Fluid Contamination

To stop blade wear, use top-grade hydraulic liquid with the right thickness. Frequent filtering clears out dirt that might harm pump parts. Keeping the liquid clean and well-maintained stretches the pump’s life and boosts its output.

Seasonal Performance Optimization

Temperature swings can affect how single vane pumps perform. In chilly settings, hydraulic liquid may thicken, cutting pump efficiency. Using liquids suited to the temperature and tweaking settings as needed keeps performance strong all year.

FAQs About Single Vane Pumps

- What distinguishes a single vane pump from a multi-vane design?

A single vane pump uses fewer blades, yielding a simpler build with less upkeep. In contrast, multi-vane pumps give higher flow rates. - How do China single vane pump factories ensure cost-efficiency?

Chinese makers streamline production and use smart machines to cut costs while keeping quality high. - Can hydraulic single vane pumps handle high-pressure tasks?

Yes, many are built to work under strong pressure, fitting them for tough jobs. - What certifications should I look for in an OEM single vane pump manufacturer?

Seek ISO and CE marks, showing they meet global quality and safety rules. - Are wholesale single vane pump factories suitable for small orders?

Some offer flexible order sizes, letting small firms buy tailored solutions without big commitments.

Innovating Fluid Power with Precision

The future of hydraulic tech leans toward clever systems and green answers. New trends, like smart sensors for live tracking and eco-friendly hydraulic liquids, are shaping the field. China plays a big role in this progress, offering high-quality, budget-friendly hydraulic solutions for world markets.

Ready to boost your hydraulic systems? Check out POOCCA’s single vane pump customization services or reach our engineers for custom answers. Let’s build efficiency together!