Introduction to Radial Vane Pumps

Radial vane pumps are critical components in hydraulic systems, widely utilized for their robust functionality and efficiency. These pumps are instrumental in various applications, including automotive, industrial, and aerospace industries. Understanding the essential functions of radial vane pumps provides insight into their operational excellence and practical applications. By delving into the mechanism and primary roles, one can appreciate the significance of these engineering marvels in maintaining system efficacy and reliability.

POOCCA Hydraulic (Shenzhen) Co., Ltd. was established in 2006 and has four companies in Hong Kong, Guangdong, Jiangsu and Zhejiang. We are a comprehensive hydraulic service company specializing in the research and development, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and related parts. With extensive experience in providing power transmission and drive solutions to hydraulic system users around the world, we have a strong reputation in the industry.

Operating Principles of Radial Vane Pumps

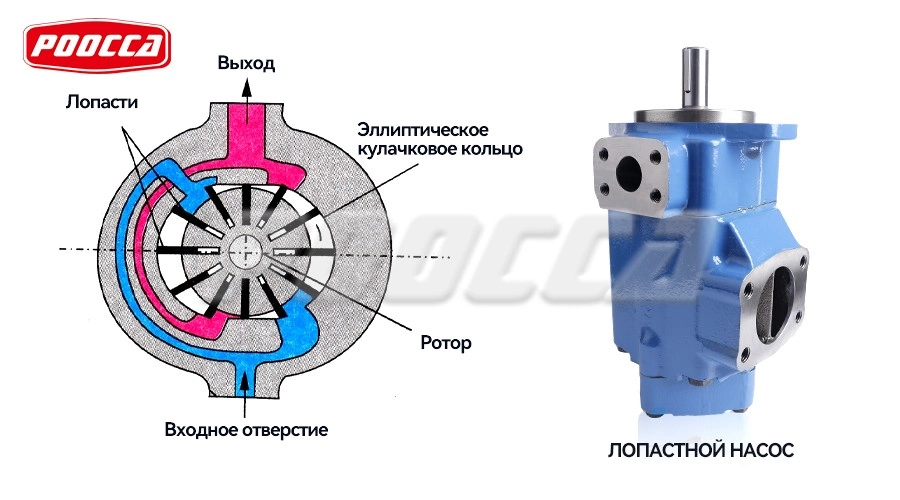

Mechanical Structure

The mechanical structure of radial vane pumps is meticulously designed to ensure optimal performance and durability. At the core, the pump comprises a rotor with multiple vanes that move radially within slots. This rotor is housed in a chamber with an eccentric bore, meaning the center of the rotor and the pump housing are offset. As the rotor turns, the vanes are forced outwards due to centrifugal force, creating a close seal against the walls of the chamber. This movement is essential in drawing and displacing fluid effectively. The precision in manufacturing these components ensures minimal leakage and consistent performance.

Fluid Dynamics

Fluid dynamics in radial vane pumps revolve around the principles of displacement and pressure equilibrium. When the rotor spins, the expanding and contracting volumes between the vanes and the pump housing enable fluid to be drawn into the inlet and expelled through the outlet. This action ensures a steady and controlled flow of fluid, which is crucial for maintaining the desired system pressure. The constant volume variation within the pump chamber aids in controlling the fluid velocity, which contributes to the pump’s efficiency and smooth operation. Proper understanding of these fluid dynamics is essential for optimizing pump performance and efficiency.

Key Functions of Radial Vane Pumps

Fluid Transfer

One of the primary functions of radial vane pumps is fluid transfer. These pumps are essential in circulating fluids within hydraulic systems, ensuring that the necessary pressure is maintained for effective operation. Radial vane pumps achieve fluid transfer through their precise mechanical action, providing a consistent and reliable flow rate. This ability to transfer fluids efficiently makes them suitable for various applications, including lubrication systems, coolant circulation, and hydraulic actuation. Their robust design ensures that they can handle a wide range of fluids, from light oils to more viscous substances.

Pressure Control

Pressure control is another critical function of radial vane pumps. These pumps are designed to maintain and regulate pressure within hydraulic systems to ensure efficient and safe operation. By varying the displacement rate, radial vane pumps can adjust the flow rate of the fluid, thereby controlling the pressure. This ability to regulate pressure is vital in applications where precise fluid control is necessary, such as in automated machinery and industrial processes. The inherent design of radial vane pumps allows for smooth operation, reducing the likelihood of pressure spikes and ensuring stable system performance.

Efficiency Improvement

Efficiency improvement is at the heart of the design philosophy of radial vane pumps. These pumps are engineered to minimize energy consumption while maximizing performance. The precise fit of the vanes against the pump housing reduces internal leakage, thereby enhancing volumetric efficiency. Additionally, the controlled fluid dynamics within the pump reduce turbulence and energy loss, ensuring that more of the input energy is converted into useful hydraulic energy. This high efficiency makes radial vane pumps an attractive choice for applications where energy savings are crucial, contributing to overall cost reductions and environmental benefits.

Advantages of Using Radial Vane Pumps

Durability and Reliability

Radial vane pumps are renowned for their durability and reliability. The robust construction and high-quality materials used in these pumps ensure they can withstand demanding operational conditions. The design minimizes wear and tear on the components, resulting in a longer lifespan and reduced maintenance needs. This reliability is vital in critical applications where pump failure can lead to significant downtime and costs. Therefore, radial vane pumps are often chosen for situations requiring consistent performance and minimal interruption.

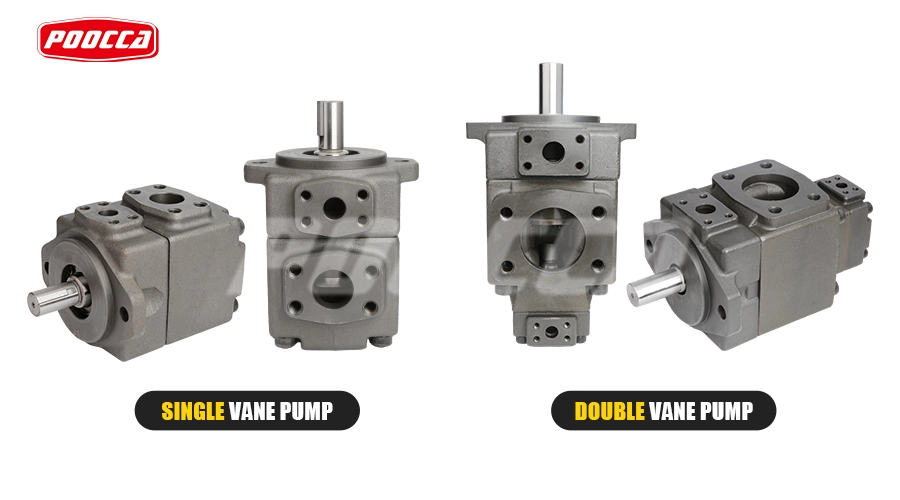

Variable Displacement Capabilities

One of the standout features of radial vane pumps is their variable displacement capability. This means that the pump can adjust the amount of fluid it displaces per cycle, allowing for precise control over fluid flow and pressure. This feature is particularly beneficial in applications requiring variable flow rates, as it enhances efficiency and flexibility. By adjusting the displacement, radial vane pumps can tailor their performance to specific operational needs, contributing to optimal system functioning.

Ease of Maintenance

Ease of maintenance is another significant advantage of radial vane pumps. Their design allows for straightforward disassembly and reassembly, making it easier to perform routine inspections and repairs. The accessibility of key components means that maintenance tasks can be carried out quickly and efficiently, reducing downtime. Additionally, the simplicity of the mechanical structure means fewer points of failure, contributing to lower maintenance costs and improved operational efficiency over time.

Applications in Different Industries

Automotive Industry

Power Steering Systems

In the automotive industry, radial vane pumps play a crucial role in power steering systems. These pumps provide the necessary hydraulic pressure to assist drivers in steering the vehicle, making it easier to turn the wheel, especially at lower speeds. Radial vane pumps are preferred in this application due to their ability to deliver consistent pressure and flow rates, ensuring smooth and responsive steering. The reliability and efficiency of these pumps contribute to the overall performance and safety of power steering systems.

Transmission Systems

Radial vane pumps are also employed in transmission systems within the automotive sector. These pumps circulate transmission fluid, which is essential for cooling and lubricating the various components within the transmission. By maintaining the appropriate pressure and flow of the transmission fluid, radial vane pumps help enhance the efficiency and longevity of the transmission system. Their ability to handle different fluid viscosities and maintain performance under varying conditions makes them an ideal choice for this application.

Industrial Machinery

Hydraulic Systems

In industrial machinery, radial vane pumps are widely used in hydraulic systems. These pumps provide the hydraulic pressure necessary to operate various machinery and equipment, such as presses, lifts, and conveyors. The precise control over fluid flow and pressure offered by radial vane pumps ensures that hydraulic systems operate smoothly and efficiently. Their robust design and ability to handle high-pressure conditions make them suitable for demanding industrial applications.

Lubrication Systems

Radial vane pumps also find applications in lubrication systems for industrial machinery. These pumps ensure a steady supply of lubricating oil to the moving parts of the machinery, reducing friction and wear. By maintaining consistent lubrication, radial vane pumps help extend the lifespan of the equipment and improve operational reliability. The efficiency and reliability of these pumps make them a preferred choice for maintaining optimal lubrication in various industrial settings.

Factors Influencing Radial Vane Pump Performance

Material Construction

The material construction of radial vane pumps significantly influences their performance. High-quality materials, such as hardened steel or specialized alloys, are typically used to manufacture the components to ensure durability and resistance to wear. The choice of materials also affects the pump’s ability to handle different fluids and withstand harsh operational conditions. Therefore, selecting the appropriate materials is crucial for ensuring the longevity and efficiency of radial vane pumps.

Operational Conditions

Temperature Range

The temperature range within which a radial vane pump operates impacts its performance and efficiency. Pumps that are designed to handle a wide range of temperatures can be used in various applications without compromising their functionality. Extreme temperatures can affect the viscosity of the fluid being pumped, as well as the expansion and contraction of the pump components. Ensuring that radial vane pumps are designed to operate within the expected temperature range of the application is vital for maintaining optimal performance.

Pressure Limits

Pressure limits are another critical factor influencing the performance of radial vane pumps. These pumps are designed to operate within specific pressure ranges, and exceeding these limits can lead to mechanical failures and reduced efficiency. Properly understanding and adhering to the pressure ratings of radial vane pumps is essential for ensuring safe and reliable operation. Regular monitoring and maintenance can help identify any pressure-related issues and prevent pump damage.

Future Trends in Radial Vane Pump Design and Technology

The future of radial vane pump design and technology is expected to focus on enhancing efficiency and sustainability. Advances in materials science will enable the development of pumps with improved wear resistance and higher performance capabilities. Additionally, incorporating smart technologies and sensors will allow for real-time monitoring and optimization of pump performance. Energy-efficient designs will also be prioritized to reduce the environmental impact and operational costs. The integration of digital technologies and automation will further streamline maintenance and improve the overall reliability of radial vane pumps.

Final Thoughts on Radial Vane Pumps

Radial vane pumps are indispensable components in various hydraulic systems due to their robust design, efficiency, and reliability. Understanding their operating principles and key functions provides insight into their critical role in fluid transfer, pressure control, and efficiency improvement. The advantages of using radial vane pumps, such as durability, variable displacement capabilities, and ease of maintenance, make them suitable for a wide range of applications across different industries. By considering factors like material construction and operational conditions, one can ensure optimal performance and longevity of these pumps. As technology advances, radial vane pumps will continue to evolve, offering even greater efficiency and sustainability in the future.

In addition to our skilled sales team, we have 18 technical experts. Poocca has rich knowledge and technical strength. Their expertise not only drives our innovation but also ensures our products and services are at the forefront of technological advancement.