Understanding Gear Type Pumps

What is a Gear Type Pump?

A gear pump is a type of positive displacement pump that uses rotating gears to move fluids. This mechanical design typically consists of two or more interlocking gears that create a sealed cavity where fluid is drawn in and then pushed out as the gears rotate. Gear pumps are commonly employed for transferring liquids in various industries due to their ability to maintain a consistent flow. Their design can vary, with options such as external gear pumps, internal gear pumps, and screw pumps, each serving specific applications dependent on the properties of the fluids being pumped.

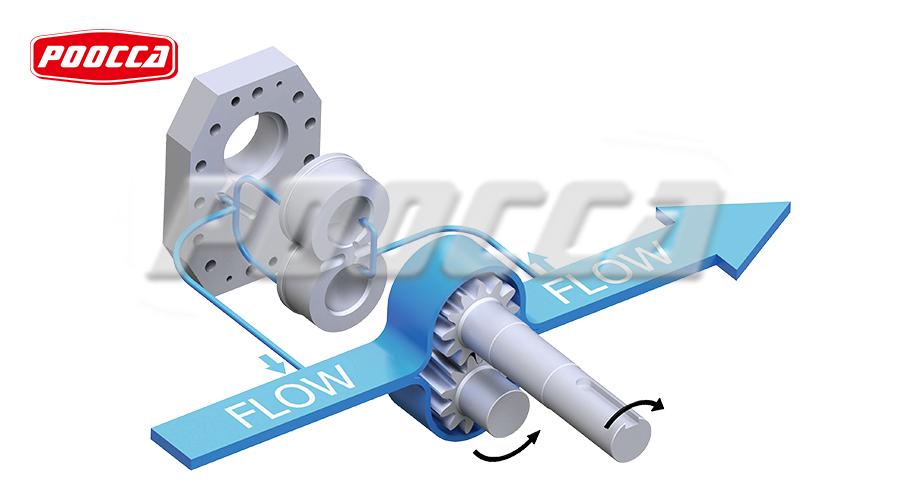

How Gear Type Pumps Work

Gear pumps function based on the principle of mechanical displacement. As the gears rotate, the space between them expands on the inlet side, which creates a vacuum that draws fluid into the pump. Following that, the rotation of the gears traps the fluid between their teeth and moves it toward the outlet side. The compressive forces generated during this movement ensure a continuous flow, ejecting fluid from the discharge side of the pump. This mechanism allows for efficient and reliable handling of diverse fluids, including those that are high in viscosity.

Primary Advantages of Gear Pumps

High Efficiency and Reliability

Gear pumps offer a benefit, in transportation thanks to their efficient design that reduces slip between the gears for effective fluid handling and better energy efficiency levels. Moreover, gear pumps are known for their reliability due to their design with moving parts compared to other pump types. This mechanical simplicity leads to maintenance needs and an extended operational lifespan making gear pumps a choice for consistent performance, across different operating scenarios.

Compact and Sturdy Design

Gear pumps with their design can easily be installed in spaces where larger pump systems would not work well. This is especially advantageous, in situations where space-efficient solutions are necessary. Their strong build usually utilizes materials that allow them to manage pressures and environments without experiencing substantial wear or harm. Their capacity to endure high-pressure settings makes gear pumps ideal, for specialized uses where toughness is important.

Versatile Application Areas

Gear pumps have a range of uses. Can be found in industries such, as chemical processing and food and beverage production as well as pharmaceutical and oil and gas sectors due to their versatility in handling different types of fluids like oils and slurries of varying thicknesses with ease by customizing gear sizes and configurations based to suit specific requirements necessary, for specific applications.

Technical Benefits of Using Gear-Type Pumps

Consistent Flow Rates

Minimal Pulsation

One key advantage of gear pumps is their capability to deliver a flow rate over time due, to their positive displacement mechanism ensuring a smooth and continuous delivery of fluids – an important factor in tasks needing accurate flow regulation. Another noteworthy aspect is the pulsation exhibited by gear pumps which results in an even output that is vital in applications requiring uniform fluid distribution. The decrease, in pulsation can enhance the efficiency of equipment and contribute to better process reliability.

Smooth Fluid Transition

The interconnected gears, in gear pumps facilitate shifts from the entry point to the exit point to improve the movement of fluids effectively and efficiently. That continuous flow plays a role in upholding the effectiveness of the system in situations with several subsequent stages or components. The decrease, in flow linked with motion boosts the overall efficiency of the pump system. Furthermore, this smoother functioning can reduce foam formation making gear pumps a choice for scenarios where capturing air could pose challenges.

Tolerance to High Viscosity Fluids

Gear type pumps exhibit a strong tolerance for high viscosity fluids, making them suitable for a range of products that are not easily pumped by other designs. Their ability to move thick, viscous materials such as lubricants, adhesives, and polymer solutions without substantial pressure losses ensures they can meet industry demands effectively. This characteristic is vital for processes that require reliable movement of such materials without delays or disruptions.

Flexibility in Pressure Handling

Another key technical benefit of gear pumps is their flexibility in handling varying pressure conditions. They can effectively operate over a broad range of pressures, allowing them to adapt to different operational requirements. This flexibility makes gear pumps an ideal choice for industries that experience fluctuations in system pressure or require high pressure for specific applications. With appropriate design modifications, gear pumps can maintain efficient operation even under high-pressure scenarios, catering to diverse industrial needs.

Specific Operational Benefits

Easy Maintenance and Longer Service Life

Gear pumps have a design that makes maintenance easier compared to complicated pumping systems, with fewer parts that can fail mechanically over time and reduce reliability overall costs for upkeep are also lower due, to the simplicity of gear pump materials used in their construction enhance durability and extend service life while minimizing replacement and downtime expenses.

Performing upkeep duties, like applying lubrication and fixing seals can be done quickly to ensure that pumps function efficiently without interruption for operators to handle accessible essential parts of the equipment for swift repairs as needed Due, to their ability to function effectively in different temperatures and pressure settings these pumps are known to endure daily wear and tear leading to a longer lifespan compared to other pump varieties. Investment, in gear pumps, enables companies to boost productivity and maintain operations, for improved long-term performance and profitability.

Cost-Effectiveness

When it comes to the upfront and ongoing expenses involved with gear-type pump usage in industries stand out for being cost options, due to their efficient fluid transportation capabilities leading to reduced energy consumption and long-term operational savings benefits due to fewer repairs and minimal downtimes thanks, to their reliability and durability. Moreover, as gear pumps are adaptable and can manage types of liquids companies can decrease the requirement, for specific pumps making their operations more efficient and cutting down costs.

In addition, to that the way gear pumps work efficiently allows them to often offer improved flow rates in comparison to pumps in situations. This increased efficiency is especially valuable in settings where each bit of effectiveness can result in money saved. Businesses gain advantages by reallocating funds that would have been used for maintenance or replacements and also face fewer disruptions, in their operations because of pump malfunctions. Investments, in gear-type pumps, can lead to benefits, in various industrial sectors and are generally viewed as a wise option.

Integration with POOCCA Products

Compatibility with POOCCA Gear Pumps

Integrating POOCCA gear pumps with existing systems can optimize performance across various operational environments. The design and engineering of POOCCA gear type pumps prioritize compatibility, making them suitable for numerous applications in industries such as chemicals, food processing, and pharmaceuticals. Their adaptability is essential for users who wish to augment current systems with reliable and efficient pumping solutions without extensive modifications. This seamless integration not only boosts the utility of existing setups but supports the rapid scaling of operations as demands change.

The exceptional performance of POOCCA gear pumps is attributed to their characteristics that cater to diverse applications effectively. All thanks, to the precision-crafted gears and robust materials used in their design that ensure longevity and efficiency standards are met with wear and tear. The incorporation of cutting-edge sealing technologies further enhances the pump’s reliability by preventing leaks and ensuring performance in demanding environments. This emphasis, on integrating the industry innovations enables POOCCA gear pumps to meet the changing market requirements efficiently.

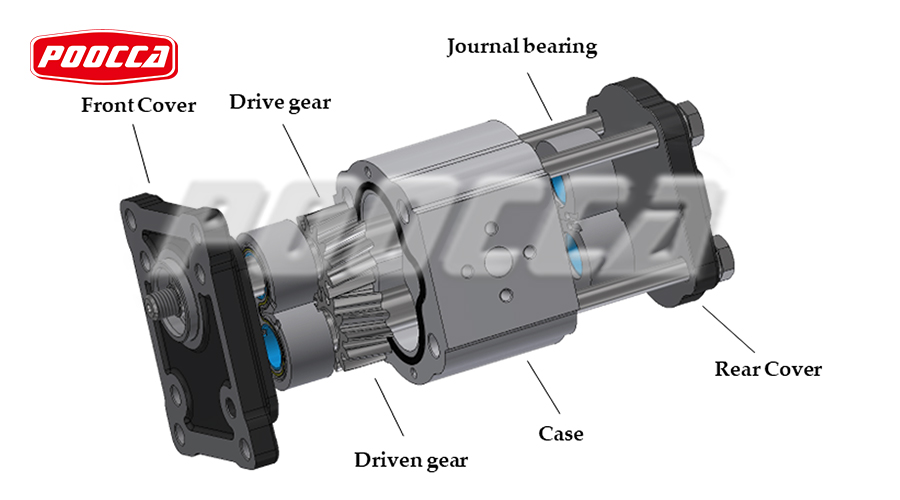

Features of POOCCA Gear Type Pumps

POOCCA gear pumps are known for their engineering design that ensures steady performance levels over time. These pumps are built with precision gears to minimize slippage and maintain a consistent flow rate vital, for operations. Moreover, Pumps often come with mounting choices. Customizable setups to seamlessly fit into different systems already in place. The pump’s ability to work with motors and control systems adds to their versatility making POOCCA gear pumps an option, for a wide range of uses.

POOCCA gear pumps offer more, than setup – they provide intuitive interface choices for monitoring and controlling functions to improve operational management effortlessly. Users can modify the pump’s performance settings as per changing process requirements with ease due to the control. Additionally, the robust materials used in crafting these pumps are notable, for their ability to endure pressure and temperature environments. The sturdy. The flexible characteristics of POOCCA gear-type pumps instill confidence, in users that they can effectively withstand industrial pressures and maintain optimal efficiency during operations.

Material Options and Customization

POOCCA gear pumps offer a selection of materials and customization options to meet the needs of industries effectively. They are designed to handle fluids with properties or high viscosities by using suitable materials. This flexibility, in material selection ensures that POOCCA gear pumps can perform well in a range of applications while meeting safety and regulatory standards.

Users can personalize gear-type pumps by adjusting design and configuration options to match their requirements accurately; whether it’s altering gear ratios modifying inlet and outlet sizes or adding custom seals. POOCCA offers the necessary flexibility to cater to various pumping needs effectively. This high level of customization is beneficial as it enables businesses to enhance their equipment performance without the need, for changes to infrastructure. In the run tailoring pump features according to utility demands can result in improved efficiency and performance, over time.

Enhancing System Performance with POOCCA Solutions

Integrating POOCCA gear pumps into a system setup enhances performance and efficiency significantly for users utilizing them in their operations. The unique design of these pumps reduces friction and energy wastage leading to flow and consistent flow rates. This reliable performance is vital, for maintaining stability and efficiency in processes, especially in precision demand industries, like pharmaceutical and food production sectors. Moreover, by decreasing pulsation levels, the gear pumps from POOCCA facilitate smoother operation downstream resulting in decreased wear and operational issues.

Incorporating cutting-edge monitoring technologies, into POOCCA solutions makes it easier for operators to preemptively tackle maintenance issues by spotting deviations from operating conditions to prevent system inefficiencies or breakdowns from occurring. The sophisticated diagnostic features guarantee the performance of gear-type pumps, in industrial environments where different pumps and machinery are interconnected. Overall utilization of POOCCA solutions empowers manufacturers to enhance the efficiency of their pumping systems over time resulting result in improved productivity and durability.

Conclusion and Next Steps

To sum up, the discussion, on gear type pumps advantages. Those produced by POOCCA. They bring benefits in terms of operational efficiency and cost-effectiveness while being adaptable to different systems. Their simple upkeep requirements along with their construction and flexible application options make them a smooth fit, for a variety of settings while reducing overall operational expenses. Businesses seeking to boost their operations might want to think about investing in gear pumps to enhance reliability and effectiveness.