What Are the Key Factors to Consider When Selecting a Hydraulic Vane Pump?

Understanding the Basics of Hydraulic Vane Pumps

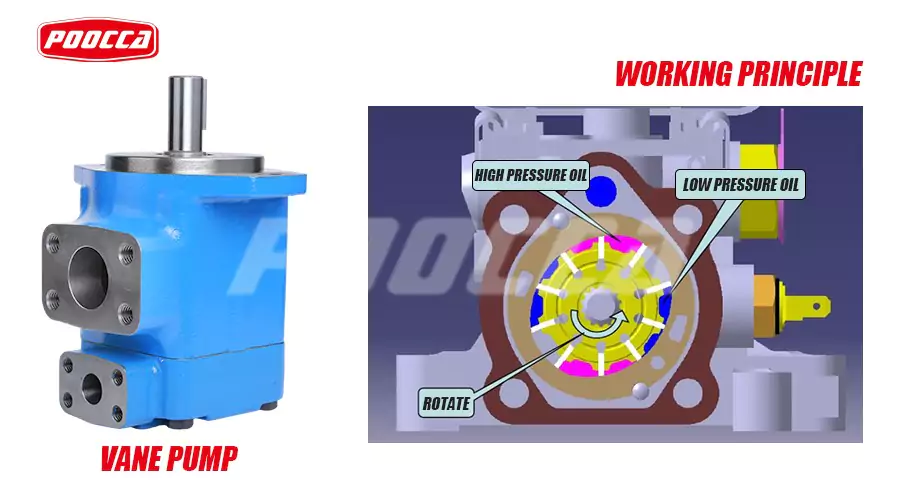

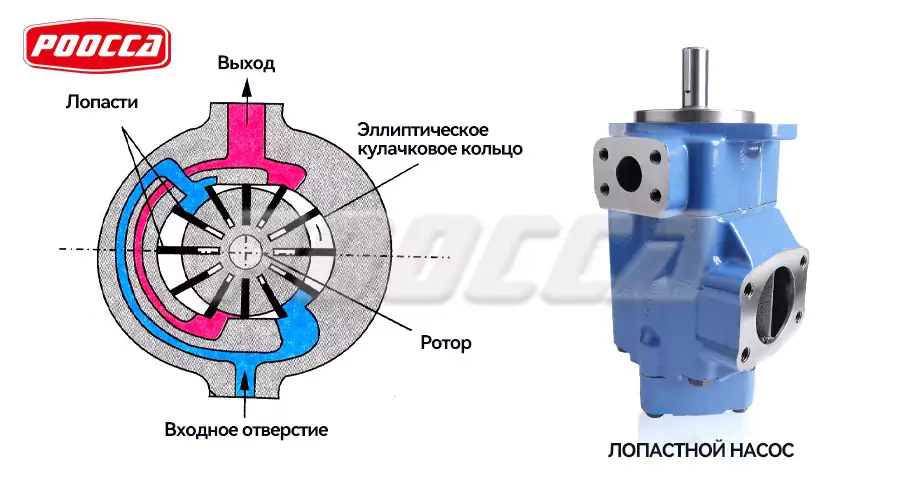

Understanding the basics of vane pumps is crucial when choosing the pump for your needs. They are valued for their efficiency and capability to manage pressure levels. The pumps function by utilizing vanes attached to a rotor that propels fluid within the pump’s enclosure. This setup enables performance and steady flow rates making them suitable for a range of uses, like industrial machinery and mobile devices.

Evaluating Performance Requirements

Performance plays a role in selecting a hydraulic vane pump for your needs. The key consideration involves evaluating the pressure and flow rate that align with your application requirements. Take the Parkers range of vane pumps like the T6 and T7 series as an example; they boast a working pressure of up to 275 bar coupled with volumetric efficiency—ideal for applications that demand reliable performance. On the other hand, Vickers VQ Series Vane Pumps stand out for their delivery rates spanning from 5 to 60 US gpm at 1200 r/min serving a range of applications, with diverse flow rate demands.

Assessing Compatibility with Your System

When choosing a hydraulic vane pump, for your system compatibility is crucial to consider compatibility, with your setup well Ensure that the pump you choose can easily integrate with your existing system For instance the Yuken PV Series Single Hydraulic Vane Pumps are crafted with built-in driving components in a cartridge assembly making it simple to replace and adapt to various industrial uses..

How Do Different Types of Hydraulic Vane Pumps Compare?

Fixed Displacement vs. Variable Displacement Pumps

Knowing the contrast between fixed displacement and variable displacement pumps can help you decide which one to choose effectively. Fixed displacement pumps such as the Eaton Vickers V Single Vane Pump maintain a flow rate irrespective of pressure fluctuations. Are ideal for scenarios that demand steady output. Conversely, variable displacement pumps alter their flow rate based on the needs of the system providing adaptability in situations, with changing loading-Stageage. Single-stage pumps offer simplicity. Require maintenance due to their fewer parts. They are commonly utilized in situations with space or where a preference for simplicity exists. On the other hand, multi-stage pumps are capable of managing pressures and offer greater performance adjustability making them well-suited for hydraulic systems, with higher demands.

How Can You Ensure Longevity and Reliability in Your Hydraulic Vane Pump?

Maintenance Practices for Optimal Performance

For your hydraulic vane pump, to be long and work reliably over time it’s crucial to follow a maintenance schedule. This involves keeping an eye out for levels checking for any leaks and replacing any parts promptly. By sticking to maintenance tasks you not only prolong the lifespan of your pump but also keep it running smoothly at its best performance level.

Troubleshooting Common Issues

Taking steps to address problems can help avoid downtime and expensive repairs, for your hydraulic vane pump systems upkeep as issues, like noise and reduced performance usually arise from air entrapment or worn-out vanes, which can be resolved by promptly inspecting seals and replacing any damaged components to ensure smooth operation.

If you’re interested in checking out high-quality hydraulic solutions options sage going to POOCCA for a range of parts designed for professional use in different industries.

In summary, choosing the hydraulic vane pump necessitates ta thoughtful evaluation of performance needs suitability with systems, and grasping the functional distinctions among different pump types. By concentrating on these factors and consistently following maintenance routines, you can guarantee that your selected pump will provide top-notch performance and dependability in the run.

Where Can You Find High-Quality Hydraulic Vane Pumps?

Introducing POOCCA: A Reliable Source for Hydraulic Solutions

It can feel overwhelming to choose the hydraulic vane pump; with POOCCA by your side, you have a trusted ally, in all things hydraulic systems! POOCCA is well known for providing a variety of parts that are crafted to meet the high standards of today’s industries. Whether it’s hydraulic vane pumps or other components like seals and motors. Rest assured that with POOCCA you get top-notch quality and performance, in every product they offer.

POOCCA’s dedication to pushing boundaries and delivering top-notch quality attracts professionals looking for solutions to improve efficiency and performance in a range of applications, like industrial machinery and mobile equipment maintenance needs.

Discover the range of solutions provided by POOCCA. See how they can enhance the performance of your system when you explore their offerings today.

What Are the Benefits of Choosing the Right Hydraulic Vane Pump?

Enhancing System Efficiency and Productivity

Choosing the hydraulic vane pump can greatly improve the efficiency and performance of your system’s operations. It is important to select a pump that can provide fluid flow and maintain the required pressure levels, for functioning. For example, Parkers T6 and T7 Vane Pumps are well regarded for their efficiency in moving fluids and handling pressures up to 275 bar making them a top choice for systems needing performance.

Select a pump that fits your needs to reduce energy waste and improve efficiency effectively to boost productivity by ensuring your system runs smoothly without any unnecessary disruptions or delays.

Improving Overall System Performance

The proper hydraulic vane pump does not boost effectiveness. Also enhances the overall performance of the system it is in. The Vickers VQ Series pumps provide operation and great efficiency which helps to make a hydraulic system dependable and set day. These characteristics are crucial, for ensuring an output, in settings where precision is key.

Furthermore choosing a pump that seamlessly fits into your system ensures that all parts function smoothly together. This compatibility minimizes the strain, on components lengthening the life of your machinery and decreasing maintenance expenses, in the run.

To sum up the discussion, picking the vane pump requires a deep understanding of your system’s requirements and choosing a pump that can effectively meet those needs. By prioritizing efficiency improvements and enhancing performance through selection processes you guarantee that your hydraulic systems function at their capacity.