Hydraulic ram cylinders play a role in industrial settings by delivering the power needed to operate heavy equipment efficiently. This piece delves into the mechanisms of hydraulic ram cylinders. Examines their definition, functionality, key components, and operational principles. Furthermore, it explores the types of cylinders and how they are utilized in various industries.

Understanding Hydraulic Ram Cylinders

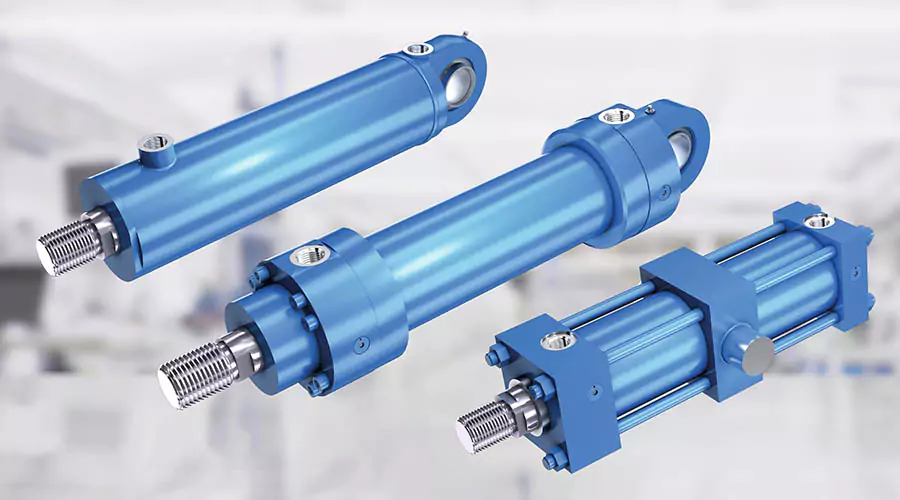

Definition and Functionality

A hydraulic ram cylinder is a mechanical actuator that utilizes pressurized fluid to produce linear motion and force. These cylinders are essential in systems where high force is required to move or lift heavy loads. They are commonly found in construction equipment like excavators and bulldozers, where they facilitate tasks such as lifting, digging, and material handling.

Core Components

The core components of a hydraulic ram cylinder include the cylinder barrel, piston, piston rod, neck gland, end caps, and cylinder ports. The cylinder barrel houses the piston which moves back and forth under fluid pressure. The piston divides the cylinder into two chambers: the cap end (bottom chamber) and the rod end (head-end chamber). The neck gland ensures a tight seal around the piston rod to prevent fluid leakage.

The Working Principle of Hydraulic Ram Cylinders

Fluid Dynamics in Operation

Hydraulic ram cylinders operate based on fluid dynamics principles. Pressurized hydraulic fluid is pumped into one side of the cylinder, creating a pressure differential that causes the piston to move. As fluid enters one chamber, it pushes against the piston surface area, generating movement while displacing fluid from the opposite chamber back to a reservoir.

Pressure and Force Generation

The force exerted by a hydraulic ram cylinder is determined by the pressure of the hydraulic fluid and the surface area of the piston. According to Pascal’s Law, this relationship can be expressed as F = P × A, where F is force, P is pressure, and A is area. This principle allows hydraulic cylinders to generate significant force with relatively low input pressure.

Types and Applications of Hydraulic Ram Cylinders

Varieties of Hydraulic Cylinders

Different kinds of cylinders are designed for uses, such as single-action cylinders which push in one direction, and double-action cylinders which can move back and forth with hydraulic power powering both sides of the piston rod. Piston cylinders without a piston or with pistons are mostly utilized for pushing tasks.

Industrial Applications

Hydraulic ram cylinders play a role in industries because of their flexibility and effectiveness. In manufacturing facilities, these cylinders are components in machines used for shaping metal sheets through stamp presses or precision forming materials. In mining sites, they enable the extraction of ores and transportation of materials by providing power to heavy-duty equipment such as drills.

Farmers in the sector use hydraulic ram cylinders in tractors and harvesters to lift and control equipment like implements and tools for various tasks on the farm fields and processing areas alike. These cylinders also play a role in conveyor systems and lifting platforms within the realm of materials handling industries to ensure operations. POOCCA stands out for its notch components that enhance performance across these different applications.

In terms of knowledge about hydraulic ram cylinders and their operation helps industries make the most of their capabilities in challenging settings effectively.

Advantages of Using Hydraulic Ram Cylinders

Efficiency and Precision

Hydraulic ram cylinders are well known for their effectiveness and accuracy in a variety of settings. By transforming energy into power these cylinders facilitate seamless and precise motions, which are essential for tasks demanding extreme precision. The capacity to apply force with pressure input enables industries to effortlessly carry out intricate operations. This efficacy lowers energy usage and operational expenses making systems the favored option in fields, like manufacturing, mines, and construction.

Hydraulic ram cylinders provide accuracy in situations where precise positioning is crucially important. For instance, in manufacturing tasks such as metal stampings or bendings where controlling the movement of machine parts is key to achieving desired results without sacrificing quality.The design of cylinders with components, like the piston and cylinder barrel guarantees repeatable movements that help boost productivity significantly.

Durability and Maintenance Considerations

Hydraulic ram cylinders are built to last in conditions. They are made from strong materials, like high-strength steel to handle heavy use over time effectively without frequent maintenance or repairs causing downtime.

Maintaining ram cylinders is pretty simple, too. Keep an eye out for any issues during regular checks and maintenance routines to catch problems early before they become big headaches! Making sure everything is well lubricated and checking for leaks in the seals while keeping an eye out for levels are some of the tasks that can help extend the life of hydraulic systems. Moreover, the improvements in seal technology make these cylinders more reliable by reducing leaks and ensuring performance as time goes by.

Innovations in Hydraulic Ram Cylinder Technology

Recent Technological Advancements

Lately, there have been some improvements in hydraulic ram cylinder technology that have boosted their effectiveness and features quite a bit. One interesting advancement is the incorporation of sensors and control systems into setups. These sensors give operators updates on factors, like pressure levels temperature fluctuations, and positioning information enabling them to closely track system performance and make well-informed choices to enhance operations.

One more progress is implementing cutting-edge materials in constructing cylinders like sturdy materials such, as alloys to lessen the weight of hydraulic systems without sacrificing their strength and durability boosting the effectiveness of machinery and cutting down on energy usage during operation.

Moreover, the advancements, in seal technology have resulted in better sealing options that reduce leakage and optimize the cylinder’s efficiency to the extent possible these seals are engineered to endure harsh conditions ensuring consistent performance even in challenging settings.

Future Trends in Hydraulic Systems

In the coming years, some trends will probably influence the evolution of hydraulic ram cylinder technology. One significant trend is the growing emphasis placed on sustainability and reducing impact. Companies are investigating eco fluids that lessen harm to the environment while still delivering top-notch performance. Moreover, there is a push towards creating systems that consume energy efficiently to decrease carbon emissions in various sectors.

A growing trend involves incorporating technology into systems on an ongoing basis, driven by the advancements, in Industry 4.0 technology which supports smart manufacturing solutions that allow connected devices to interact seamlessly within industrial settings. This connectivity facilitates the implementation of maintenance techniques through data analysis enabling the anticipation of malfunctions before they happen.

In addition to that the progress made in manufacturing methods shows potential for personalizing parts with exceptional accuracy and efficiency. Speed This ability enables the creation of customized solutions that fulfill precise industry needs while cutting down on production wait times.

In summary, hydraulic ram cylinders are parts used in industries because of their effectiveness, accuracy, longevity, and ability to keep up with technological advancements. As advancements, in this area push forward POOCCA leads the way by providing top-notch solutions that improve performance in a variety of applications.