The Working Principle of Hydraulic Motors

Fluid Dynamics in Hydraulics

Fluid dynamics is the core principle behind the functioning of hydraulic systems, including hydraulic motors. Hydraulic fluid—typically oil—is pressurized by a pump and then directed through the system towards the hydraulic motor. The high-pressure fluid transmits energy by flowing through passages and applying force to various motor components, such as pistons or gears. The efficiency of fluid dynamics within a hydraulic motor is essential, as it determines how effectively the motor converts hydraulic energy into mechanical energy. Good fluid dynamics ensure minimal energy loss and optimal performance.

Energy Conversion Process

The energy conversion process in hydraulic motors involves transforming the hydraulic energy conveyed by the pressurized fluid into mechanical power. When the pressurized fluid enters the motor, it acts on mechanical components such as pistons or gears, generating linear or rotational motion. For instance, in piston motors, the fluid pressure moves the pistons linearly, and through a series of mechanical conversions, this linear motion is transformed into rotational motion of the drive shaft. Gear motors, on the other hand, utilize the meshing of gears to achieve similar results. This process of energy conversion is critical, as it influences the output power, efficiency, and overall functionality of the hydraulic motor.

Starting and Stopping Mechanisms

The starting and stopping mechanisms of hydraulic motors are fundamental to their operation and control. When the hydraulic system is activated, the pressurized fluid flows into the motor, initiating movement almost instantaneously due to the fluid’s incompressibility. Controlling the start and stop of a hydraulic motor is typically done through valves, which regulate the fluid flow. Shut-off valves can start or stop the fluid flow, thereby controlling the motor’s operation. Additionally, fine-tuning control can be achieved using variable displacement designs in some motors, allowing for precise modulation of speed and torque. The responsiveness and control afforded by these mechanisms make hydraulic motors highly suitable for applications demanding quick and accurate movements.

Applications of Hydraulic Motors

Industrial Uses

Hydraulic motors play a vital role in various industrial applications due to their robustness and adaptability.

Manufacturing Machinery

In manufacturing settings, hydraulic motors are commonly used in machinery such as conveyor belts, presses, and robotic arms. Their ability to deliver consistent high torque makes them ideal for tasks that involve heavy lifting, repetitive cycles, and precision operations. Whether it’s driving a cutting machine or powering an assembly line, the reliability and efficiency of hydraulic motors contribute significantly to manufacturing productivity.

Construction Equipment

Construction equipment like excavators, bulldozers, and cranes rely heavily on hydraulic motors. These motors provide the massive force required to perform tasks such as digging, lifting, and moving heavy materials. Due to their high power density and capability to operate in harsh conditions, hydraulic motors are indispensable in construction projects. Their quick response and adaptable power output ensure that machinery operates efficiently, enhancing overall project timelines and safety.

Automotive Applications

In the automotive sector, hydraulic motors are utilized for their exceptional efficiency and reliability.

Power Steering Systems

One notable application of hydraulic motors in automotive systems is power steering. Hydraulic motors in power steering systems help drivers turn the vehicle with minimal effort by using pressurized fluid to assist with the steering mechanism. This not only enhances driving comfort but also improves vehicle control and safety. The precision and responsiveness of hydraulic motor-driven power steering ensure superior handling and maneuverability.

Hydrostatic Drives

Hydrostatic drives in vehicles use hydraulic motors to transmit power from the engine to the wheels. This system provides several advantages, such as stepless speed variation, high torque at low speeds, and smooth acceleration. Hydrostatic drives are particularly beneficial in heavy-duty vehicles like tractors and forklifts, where they contribute to superior performance and durability. The versatility of hydraulic motors in these applications demonstrates their crucial role in advancing automotive technology.

Advantages and Disadvantages of Hydraulic Motors

Benefits

Hydraulic motors offer several notable benefits that make them suitable for various applications.

High Power Density

One of the primary advantages of hydraulic motors is their high power density. This means they can deliver a significant amount of power relative to their size and weight. This attribute makes hydraulic motors highly effective in applications where space and weight considerations are critical, such as in aerospace or compact mobile machinery.

Efficiency in Heavy-Duty Operations

Hydraulic motors are renowned for their efficiency in heavy-duty operations. They can continuously deliver high torque under demanding conditions, such as in construction and industrial machinery. This makes them reliable components that can endure rigorous operational requirements while maintaining performance, contributing to cost savings through reduced downtime and maintenance needs.

Limitations

Despite their advantages, hydraulic motors also come with certain limitations.

Sensitivity to Contamination

Hydraulic motors are sensitive to fluid contamination, which can significantly impact their performance and lifespan. Contaminants like dirt, metal particles, or water can cause wear and tear, leading to malfunctions or failures. Therefore, maintaining clean hydraulic fluid and implementing effective filtration systems is crucial to avoid damage and ensure the longevity of the motor.

Maintenance Requirements

Another limitation is the maintenance requirements associated with hydraulic motors. Regular maintenance is essential to keep the system operating efficiently and to prevent issues arising from fluid leaks, seal wear, or component degradation. This includes routine inspections, fluid changes, and the replacement of worn parts. While these maintenance activities ensure optimal performance, they can also increase operational costs and require skilled personnel.

Key Considerations When Choosing a Hydraulic Motor

Performance Specifications

Selecting the right hydraulic motor involves evaluating several performance specifications.

Pressure and Flow Rate Requirements

Understanding the pressure and flow rate requirements of the application is crucial. Hydraulic motors need to match the system’s pressure capabilities to ensure efficient operation and avoid damage. The flow rate determines the motor’s speed and must be compatible with the pump’s capacity to deliver the desired performance. Choosing a motor that aligns with these specifications ensures optimal efficiency and functionality.

Environmental Conditions

Environmental factors also play a significant role in the selection process.

Temperature Tolerance

Hydraulic motors must operate within the temperature ranges they are designed for. Extreme temperatures can affect fluid viscosity and motor components, impacting performance and reliability. Therefore, selecting a motor with appropriate temperature tolerance ensures it can function effectively in the given environmental conditions, whether in freezing climates or high-temperature industrial settings.

Contamination Resistance

Considering the motor’s contamination resistance is vital, especially in dirty or hazardous environments. Motors designed with robust seals and filtration systems can better withstand exposure to contaminants, thus extending their operational lifespan. Ensuring that the motor can handle the specific environmental challenges of its intended application is key to maintaining efficiency and reducing maintenance needs.

By understanding the intricacies of hydraulic motors, their working principles, and specific applications, as well as carefully evaluating their advantages, limitations, and key selection criteria, users can effectively leverage these powerful devices to meet their operational needs. Hydraulic motors’ versatility, power, and efficiency make them essential components across diverse industries, from manufacturing to automotive applications.

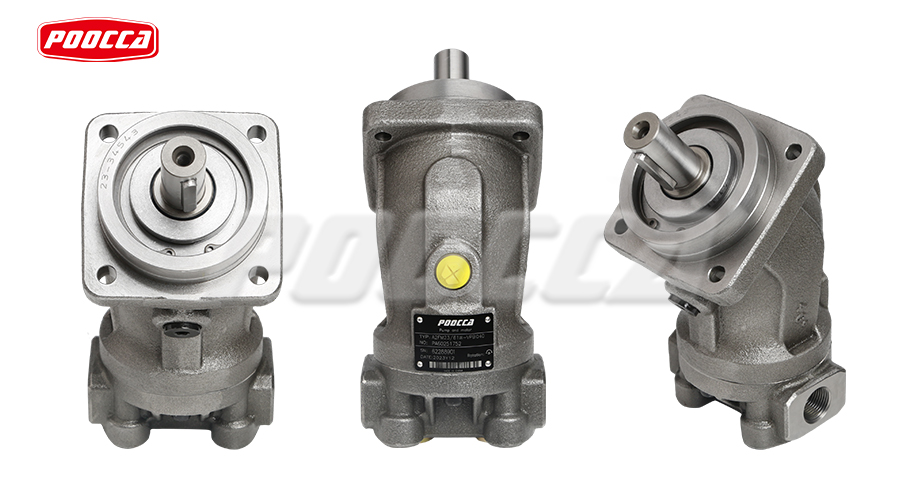

Finally, in order to ensure quality, we must also choose a trustworthy brand.

POOCCA offers a range of hydraulic motors designed to meet various industrial needs. One of their popular products is the Poclain MS MSE Hydraulic Motor. These motors are specifically designed to increase productivity without compromising on consumption. They have a full displacement range from 450 cm3/rev to 10,019 cm3/rev and can operate at a maximum pressure of 450 bar. With a maximum speed of up to 590 RPM, these motors are known for their high productivity and efficiency. They are suitable for heavy machinery and industrial applications where high performance is required.

Another notable hydraulic motor offered by POOCCA is the Eaton Vickers 6000 Series Hydraulic Motor. These motors are highly adaptable and deliver high continuous torque with a substantial flow rate. They offer up to 1685 Nm of continuous torque and a flow rate of 150 liters per minute. Available in 9 displacements ranging from 195 cm3/rev to 985 cm3/rev, these motors are designed to meet specific application requirements. They are commonly used in heavy-duty hydraulic systems, such as construction equipment and large machinery, that require high torque and flow rates.

POOCCA also offers the Parker TB Series Light Duty Motors, which are rugged and lightweight hydraulic motors designed for durability and efficient performance. These motors come in a range of models with varying displacements and torque capabilities. They can handle intermittent pressures up to 2400 psi and offer torque up to 4700 lb-in. With features like high-pressure shaft sealing, rolling blade automatic wear compensation, and full-flow internal cooling and gasketing, these motors are ideal for light to medium duty applications where durability and moderate loads are required.

Overall, POOCCA’s hydraulic motors are known for their performance, efficiency, and reliability. They cater to a wide range of industrial applications and provide solutions for increased productivity and reduced fuel consumption.