Gear pumps are essential components in hydraulic systems, providing efficient fluid transfer and power transmission. Understanding how gear pumps work is crucial for optimizing their performance. These pumps operate based on the principle of positive displacement, utilizing the meshing of gears to create a continuous flow of fluid. As the gears rotate, they create chambers that trap and transport the fluid from the inlet to the outlet. This deep dive into the operational mechanisms of gear pumps will unravel the intricacies of their design and shed light on their vital role in various industries.

What Are Gear Pumps?

Definition and Basic Components

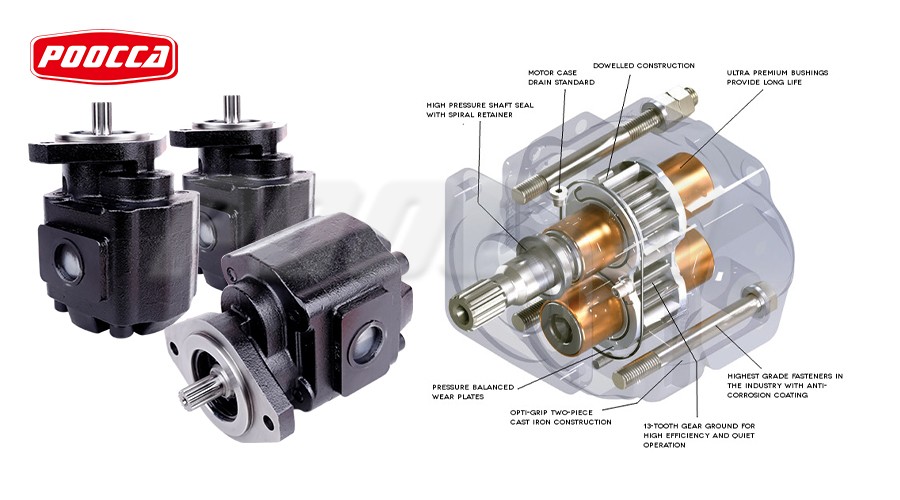

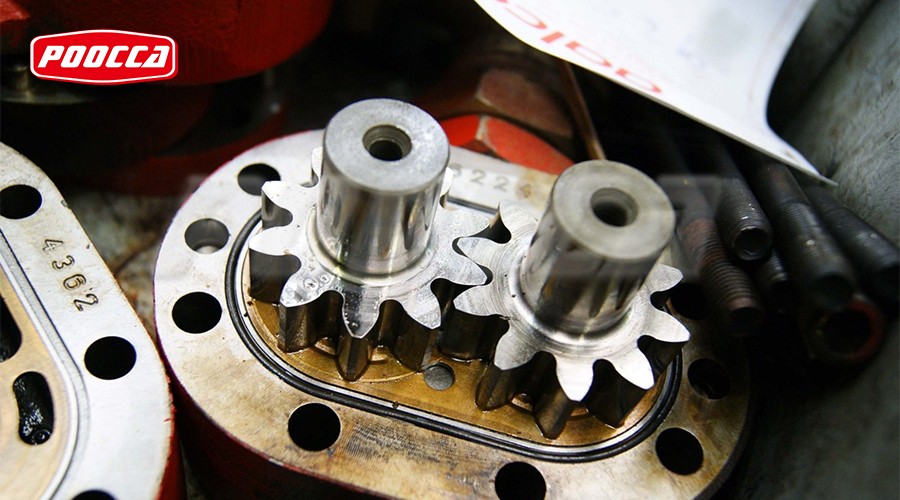

Gear pumps belong to a category of displacement pumps that use gears to move fluids around efficiently and effectively. They consist of two or more gears that work together smoothly and rely on the rotation of the gears to pull fluid into the pump and push it out into the system. The main parts include a casing to enclose everything securely, two gears interlocking smoothly and bearings supporting their movement.

Types of Gear Pumps

There are kinds of gear pumps used in a variety of applications there. External gear pumps are popular. Typically have two gears that turn in directions. In contrast, to this design is the internal gear pump where a smaller gear moves within one for a setup. When it comes to materials used in the construction of gear pumps include aluminum and cast iron or even a mix of metals based on the pressure and temperature needs.

How Do Gear Pumps Operate?

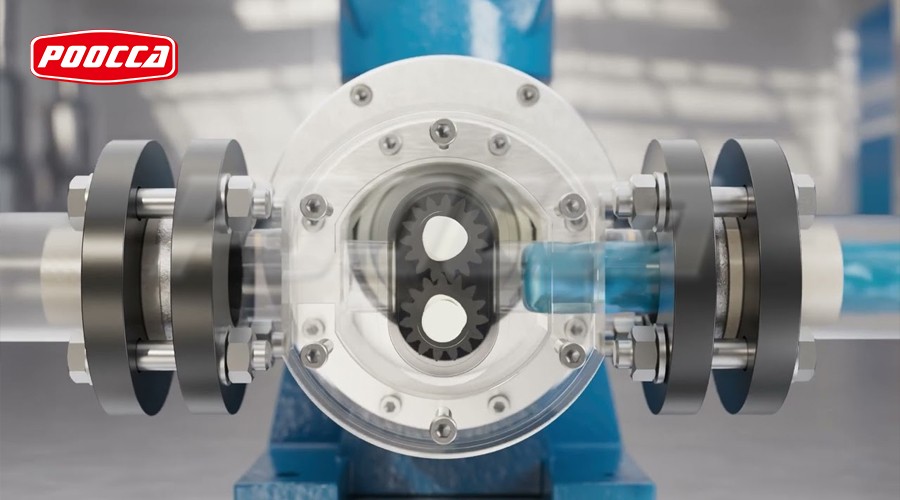

The Working Principle

Gear pumps operate based on the interaction of the gears meshing together as they rotate the forward motion of the fluid by trapping it in spaces between the teeth and casing before transporting it to the discharge side without any interruption or pulsation effect. The fit of the gears helps reduce leakage and improve overall efficiency.

Direction of Flow

The gear pump’s flow direction is controlled by the gear’s movement. Can be reversed to accommodate uses in hydraulic systems such as pumping or dumping functions.

Applications Across Industries

Gear pumps are well known for their flexibility. Find use in sectors such as construction and automotive industries as well as manufacturing settings. They are particularly adept at handling fluids which makes them suitable for tasks in hydraulic systems, lubrication, and industrial operations where consistent fluid movement is crucial.

How to Optimize Gear Pump Performance?

Proper Installation Techniques

To achieve the results from gear pumps, it is important to install them in the beginning stage. To prevent early wear, it is essential to align the pump and motor properly. Additionally, by choosing the right mounting position and using suitable seals you can preserve performance and lengthen the pumps durability.

Optimized Operating Settings

Making adjustments to settings like pressure and temperature plays a role in enhancing pump efficiency substantially. It’s crucial to keep a close eye on these factors regularly to avoid any operational glitches. Establishing a maintenance routine to inspect oil viscosity and filter conditions ensures that gear pumps operate at their best performance level reducing the chances of any potential breakdowns.

Advanced Monitoring Systems

Using monitoring systems can help prolong the lifespan of gear pumps. By employing sensors to monitor pressure flow rate and temperature real-time data insights can be obtained, allowing for adjustments and early detection of issues before they worsen. These proactive steps guarantee peak performance and dependability.

Challenges and Troubleshooting

Common Issues Encountered With Gear Pumps

Gear pumps may encounter difficulties like cavitation and overheating despite being efficient in their operation; these issues can result from factors such as supply and improper lubrication at high speeds of operation.

Troubleshooting Tips

Regular maintenance is crucial for troubleshooting gear pump problems. Explore for leaks in the seals. Ensure lubrication flow and system pressure check to address common issues. Replacing gears and bearings promptly can minimize downtime. Keep the performance at its best.

For superior gear pump solutions, consider POOCCA’s renowned product range, including the SGP and SGP2 Series Gear Pumps, engineered for exceptional performance in demanding environments. Our offerings are designed for diverse applications in civil construction machinery, industrial vehicles and more.

At POOCCA, we are dedicated to delivering total solutions that cater to all your needs. With our extensive range of products and exceptional services, we strive to make your purchasing experience accurate, time-saving, easy, and enjoyable.

Our team at POOCCA is our greatest strength. With over 300 professionals, including 70 experienced sales professionals, we possess in-depth knowledge and expertise in the hydraulic industry. Our sales team is committed to providing tailor-made solutions and exceptional services to our valued clients. We understand the importance of understanding your unique requirements and delivering the right solutions.

Our sales team is backed by 18 experts who play a role in driving innovation and keeping our products and services up to date with the latest technological advancements. With our expertise and technical knowledge, we are able to offer state-of-the-art solutions that cater to a range of customer requirements.

POOCCA boasts state-of-the-art facilities, including a 2,000 square meter office space and a factory covering over 8,000 square meters. The production space of 6K meters is fully equipped with manufacturing tools like flexible machining centers and CNC gear grinders. Not to mention coordinate measuring machines! With these high-tech gadgets at our disposal, we cater to industries by providing a range of hydraulic products for the construction and agriculture sectors among others such as bending machinery and injection molding equipment.

We have built relationships with known companies like Rexroth, Parker, Shimazu, Vickers, Danfiiss Marzozi, Yuken, Casappa, and others as a reputable provider. This guarantees that our hydraulic items adhere to standards of excellence and dependability. Discover our selection of solutions and enjoy our top-notch services. Trust POOCCA, for all your requirements. Allow us to bring exceptional value to your business.