Rotary Vane Pumps: Design and Working Principles

How Does a Rotary Vane Pump Work?

Basic Mechanism of Positive Displacement

A rotary vane pump operates as a positive displacement pump. It transfers a consistent volume of liquid per rotation. So, is a vane pump positive displacement? Indeed, it is. Inside, a rotor sits off-center within a circular casing. This rotor contains multiple slots. Each slot houses a flat blade, known as a vane.

As the rotor spins, centrifugal force propels the vanes outward. These vanes glide along the casing’s inner surface. Consequently, small compartments form. They lie between the vanes, rotor, and casing. As the rotor turns, these compartments expand and contract. This action draws in liquid and expels it. The straightforward design ensures effective fluid movement. It performs reliably even under pressure.

Key Components: Single-Stage vs. Double-Stage Rotary Vane Pumps

Rotary vane pumps come in two varieties. These are single-stage and double-stage. A single stage rotary vane pump features one vane set. It undergoes a single compression cycle. Typically, it serves low pressure vane pump needs, such as lubrication or cooling. Conversely, a 2 stage rotary vane vacuum pump or double stage rotary vane vacuum pump has two vane sets and chambers. This enables a stronger vacuum or higher demands.

Both types find extensive industrial use. Their suitability depends on required vacuum or pressure levels. The china single stage rotary vane vacuum pump system product is a favored option. Businesses value its dependability and affordability for medium-duty tasks.

Types of Hydraulic Vane Pumps and Their Industrial Applications

High-Pressure vs. Low-Pressure Vane Pumps

High-Pressure Vane Pumps

A high pressure vane pump manages pressures up to 320 bar. Pumps like the Parker T6 or T7 series excel in robust equipment. Examples include injection molding machines or industrial presses. They endure intense force. They deliver steady flow. These pumps are energy-efficient. They operate quietly. They resist contaminants like dirt. Such traits make them perfect for production lines. They also suit automated systems.

Low-Pressure Vane Pumps

A low pressure vane pump, such as those in the Berarma PLP Series, supports lubrication systems. It aids coolant circulation too. These applications typically function below 120 bar. Such pumps are cost-effective. They require minimal upkeep. Industries use them where high pressure isn’t needed. Yet, a constant flow is essential.

Variable Displacement Vane Pumps

Adaptive Flow Control for Dynamic Systems

A variable displacement vane pump adjusts fluid output based on system needs. This benefits equipment with variable power demands. For instance, HVAC systems or excavators use these pumps. They control liquid flow precisely. This conserves energy. It simplifies system management. Additionally, it reduces component wear. As a result, maintenance needs decrease over time.

Key Industrial Applications of Hydraulic Vane Pumps

Material Handling and Construction Equipment

Hydraulic Cylinder Actuation

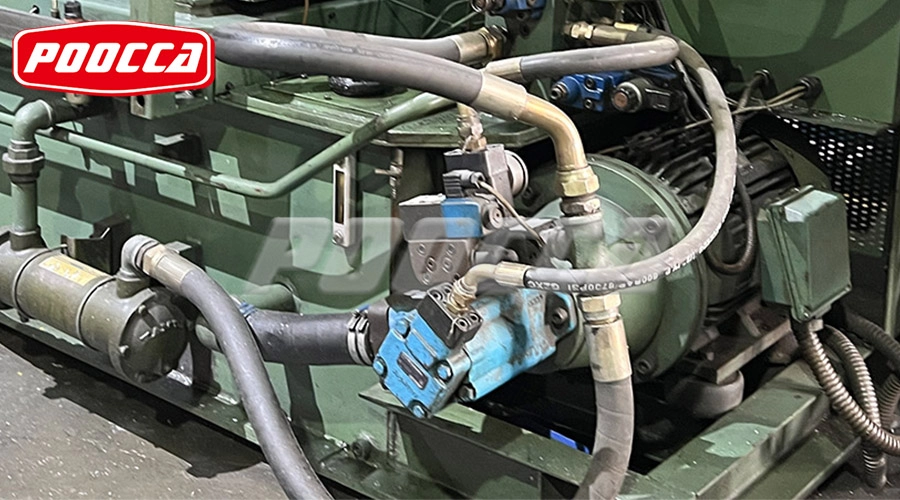

Forklifts and construction machinery rely on vane pumps. They power hydraulic cylinders. These enable smooth lifting and lowering of heavy loads. The pumps’ compact size suits tight spaces. Their low noise enhances work environments. Quiet operation is valued where sound matters.

Power Steering Systems

In agriculture and off-road vehicles, vane pumps assist power steering. They ensure smooth control. This aids precise maneuvering, even at low speeds. Large vehicles benefit greatly from this reliability.

Manufacturing and Machine Tools

Injection Molding Machines

High pressure vane pumps, like the Parker T7 series, secure molds during molding. They maintain constant pressure. They shorten cycle times. This boosts part production speed. Consistency remains high.

CNC Machinery Lubrication

CNC machines operate for extended periods. They need reliable lubrication to prevent overheating. Low pressure vane pumps provide steady lubricant flow. Their quiet performance reduces workshop noise. Installation in confined spaces is straightforward.

Automotive and Aerospace

Brake and Fuel Systems

In vehicles and aircraft, compact rotary vane pumps manage fuel or brake fluids. They’re small yet resilient. They perform reliably under stress. Their light weight avoids adding bulk. This enhances efficiency in cars and planes.

Advantages and Disadvantages of Rotary Vane Pumps

Pros: Why Industries Prefer Vane Pumps

Compact Design and Low Noise

A key advantage of rotary vane pump is its small footprint. It integrates easily into compact equipment. Examples include electric forklifts or mobile robots. Moreover, it generates less noise than gear or piston pumps. This suits environments prioritizing quietness.

Long Service Life with Minimal Maintenance

Rotary vane pumps use superior components. Many incorporate ISO-certified materials. This ensures durability. Repairs are seldom needed. Designs with double-lip vanes reduce wear further. They enhance longevity significantly.

Cons: Limitations to Consider

Sensitivity to Contaminants

A downside is sensitivity to impure fluids. Without proper filtration, vanes may wear rapidly. Damage can occur. Advanced models use improved seals. Better materials help too. Still, clean fluid systems are essential.

Pressure Limitations in Single-Stage Models

Single stage rotary vane pumps struggle with very high pressures. For intense tasks, multi-stage systems are better. Alternatively, gear or piston hybrids may work. Yet, single-stage pumps excel in low to mid-range pressure tasks.

Choosing the Right Vane Pump: Supplier Insights

China Single-Stage Rotary Vane Vacuum Pump Suppliers

Key Criteria: Customization, Stock Availability, and Certification

Selecting a supplier requires scrutiny. Look for expertise and certifications. Ensure product availability. China single stage rotary vane vacuum pump suppliers, like POOCCA , offer diverse options. They provide customization too. With over 20 years of experience, POOCCA meets global standards like ISO.

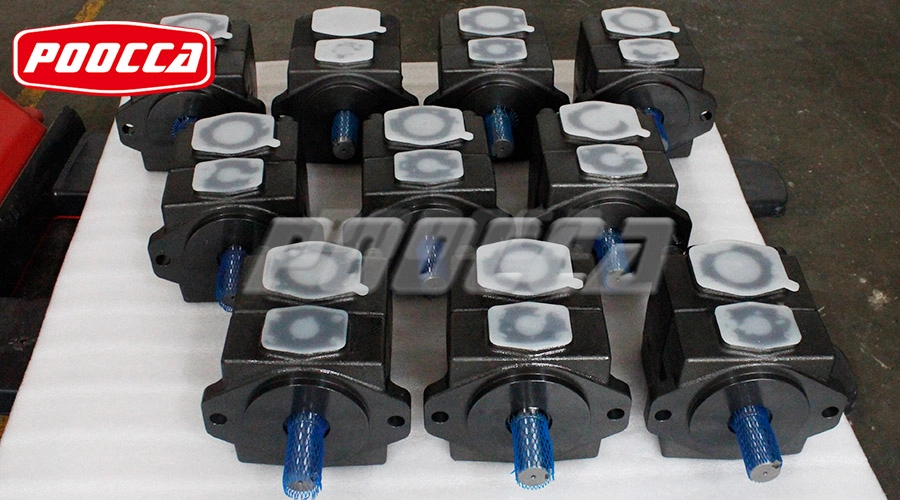

Case Study: POOCCA’s Parker-Compatible Solutions

POOCCA manufactures pumps matching Parker’s T6 and T7 series. These serve high pressure vane pump systems across industries. Customers praise POOCCA’s swift delivery. They value robust performance. Competitive pricing adds appeal.

Innovative Call-to-Action: Partner with POOCCA for Tailored Solutions

Explore POOCCA Hydraulic Vane Pump Customization Service

Fast Delivery and 12-Month Warranty

POOCCA provides single, double, and triple vane pumps. Many are readily available. They offer a 12-month warranty. This assures reliability. Whether seeking a high pressure vane pump or variable displacement vane pump, POOCCA delivers.

Request a Free Consultation

Want to enhance your hydraulic systems? Contact POOCCA today. Their engineers offer free consultations. They guide you to the best pump. This could be a low pressure vane pump or double stage rotary vane vacuum pump. Let POOCCA elevate performance. Their solutions are efficient, dependable, and cost-effective.