Understanding Axial Hydraulic Piston Pumps

What Is an Axial Hydraulic Piston Pump?

An axial hydraulic piston pump is a robust and effective device. It powers numerous hydraulic systems. The term “axial” refers to pistons moving parallel to the drive shaft. This pump pressurizes liquid. It circulates it through a system. Thus, it energizes equipment. The axial hydraulic piston pump thrives in sectors like construction, agriculture, and manufacturing.

Compared to other pumps, such as radial or gear types, axial pumps are often more compact. They offer greater efficiency. They excel in confined spaces. Yet, they deliver potent performance. Consequently, engineers and technicians favor them. They suit demanding environments perfectly.

Key Components of an Axial Piston Pump

The axial piston pump components ensure functionality and efficiency. These parts collaborate seamlessly. They maintain smooth operations.

The cylinder block houses multiple pistons. These are arranged circularly. It rotates with the shaft. This allows pistons to slide in and out. The pistons and plungers use durable materials. They withstand intense pressure. Their motion drives the pumping action. It moves liquid effectively.

The swashplate, or tilt plate, is another vital element. It regulates piston travel distance. Adjusting its angle alters liquid output. Pumps with adjustable angles are variable displacement models. They offer flexibility in flow control.

The valve plate directs liquid flow. It manages entry and exit from pump chambers. It functions like a gate. The housing and shaft provide structural support. They enable rotation. They ensure stability.

These elements are essential. They define pump performance. Understanding their roles aids in selecting the right pump.

How an Axial Piston Pump Works

Mechanical Structure and Operation

Curious about axial piston pump how it works? Let’s simplify the process. The cylinder block spins with the shaft. Pistons reside in this block. They’re influenced by the swashplate. It pushes them back and forth.

As a piston retracts, it creates a vacuum. This draws liquid into the cylinder via the inlet. When it advances, it expels liquid through the outlet. Each piston repeats this cycle. The result is a consistent liquid flow.

The swashplate’s angle controls output volume. A steeper angle increases flow. A shallower angle reduces it. Some pumps have fixed swashplates. Others adjust dynamically. These are variable displacement pumps. They adapt to changing liquid demands swiftly.

This control optimizes equipment efficiency. It explains the popularity of axial piston pumps. They excel in diverse hydraulic systems.

Applications of Axial Piston Pumps

Axial hydraulic piston pumps serve various sectors. In heavy equipment, they power hydraulic arms and tools. They’re crucial for excavators and tractors. These machines rely on their strength.

In industrial environments, these pumps support presses and conveyors. They supply force to move materials. They also aid in assembling components.

Mobile equipment benefits too. Trucks, cranes, and mining machines use them. These pumps provide high power in compact forms. They meet rigorous demands efficiently.

In high-pressure scenarios, like aerospace or metal forming, they perform reliably. Their consistency ensures safety. Precision remains paramount.

Advantages and Disadvantages of Axial Piston Pumps

Key Advantages

The axial piston pump advantages and disadvantages are noteworthy. Benefits often outweigh drawbacks. A primary strength is high efficiency. These pumps convert energy effectively. They minimize waste. Their power density is impressive. They deliver robust performance in small packages.

Adjustable flow rates enhance versatility. Variable displacement models excel here. They adapt to diverse tasks. This conserves energy. Their compact design suits tight spaces. Yet, they handle high-pressure duties effortlessly. Such qualities make them vital in advanced sectors.

Challenges and Limitations

Despite their strengths, challenges exist. Their design is intricate. This complicates repairs. Maintenance demands diligence. Regular checks prevent failures.

Contamination poses risks. Dirt or particles harm components. Clean liquids are crucial. Effective filtration is non-negotiable.

Noise and vibration can occur. Proper installation mitigates this. Quality components help too. Weighing pros and cons guides pump selection.

Top Axial Piston Pump Manufacturers

Leading Brands and Their Offerings

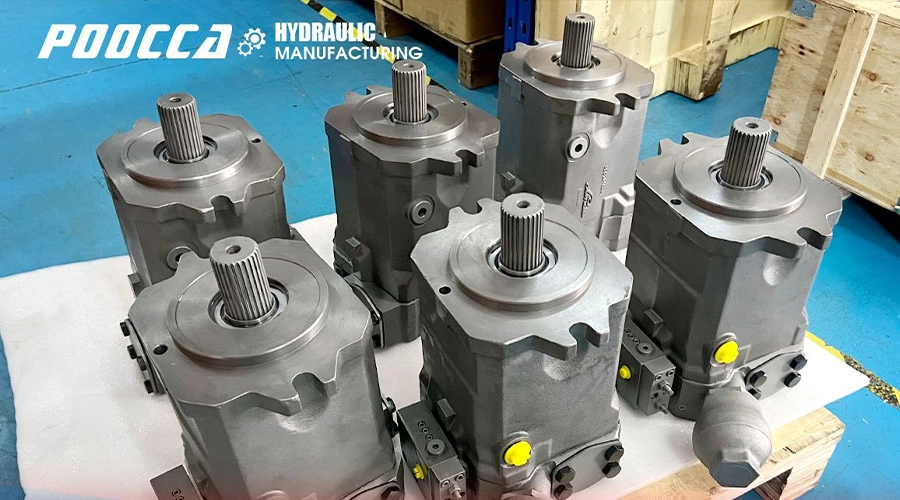

Numerous companies produce axial hydraulic piston pumps. Some earn greater trust. POOCCA stands out as a dependable supplier. They offer tailored solutions. Options include displacement and mounting customization. Even logo branding is available. Their products ensure rapid delivery. They boast factory-direct pricing. A 12-month warranty adds confidence.

POOCCA’s popular models include A10VSO, PV, A2F, A4VSO, and PVQ series. These undergo rigorous testing. They meet stringent standards. They’re ideal for demanding sectors. Buyers seeking quality and flexibility choose POOCCA. They rank high among axial piston pump manufacturers.

Other renowned names include Rexroth, Parker, Denison, Nachi, and Yunken. These brands produce durable, efficient pumps. They power global equipment extensively.

Choosing the Right Manufacturer

Selecting a supplier requires care. Prioritize reliability. Seek robust customization. Technical support is vital. POOCCA excels in these areas. They collaborate closely with clients. They deliver precise solutions. This dedication builds trust. It positions POOCCA as a preferred partner.

Case Studies and Real-World Applications

Industrial Machinery

Axial hydraulic piston pumps shine in practical settings. Consider POOCCA pumps in automotive presses. These systems shape car parts. They demand steady pressure. POOCCA’s pumps provide it efficiently. Their reliability enhances productivity.

Construction Equipment

In construction, excavators rely on these pumps. They ensure precise pressure control. They respond swiftly to demand shifts. This promotes smooth, safe operation. Their durability reduces downtime. Cost savings follow naturally.

Conclusion and Call to Action

Why Axial Piston Pumps Are Essential for Hydraulic Systems

Axial hydraulic piston pumps are potent and versatile. They offer adjustable flow. They suit myriad industries. Their compact design delivers high performance. They’re ideal for high-pressure tasks.

Get Started with POOCCA’s Custom Solutions

Need a dependable pump? POOCCA offers tailored answers. They provide custom displacement and mounting. Rapid delivery is standard. Their pumps ensure top-tier quality. Branding options are available too.

Contact POOCCA today to explore POOCCA’s axial hydraulic piston pumps. Unlock precision for your hydraulic systems!