Understanding the Mechanism of Hydraulic Gear Pumps

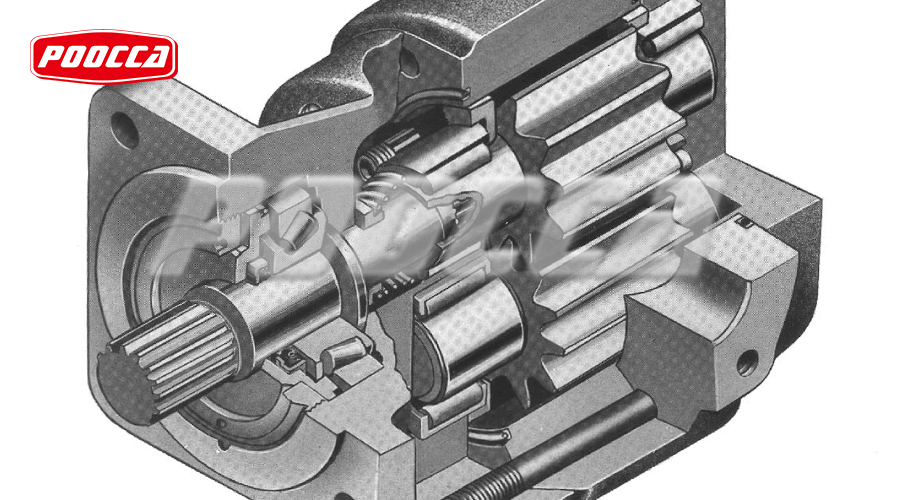

Hydraulic gear pumps play a role, in power systems as they serve as the core of hydraulic equipment by converting mechanical energy into hydraulic energy using fluid motion within a casing created by two rotating gears pulling in the fluid through a vacuum mechanism and pushing it out at high pressure through the discharge port to power different functions in the hydraulic system.

Hydraulic gear pumps are efficient, due to their practical design approach. They establish a chamber by meshed gears to minimize leakage that often plagues pump systems. This design not only boosts the transmission of power but also guarantees durability and trustworthiness in industrial settings. Thanks to their assembly process these pumps enable flow rates and pressure increments making them a vital selection, for demanding tasks.

Core Functionality of Hydraulic Gear Pumps

Hydraulic gear pumps are designed to ensure flow and pressure, within systems by employing a positive displacement mechanism that moves a fixed volume of fluid, per cycle.

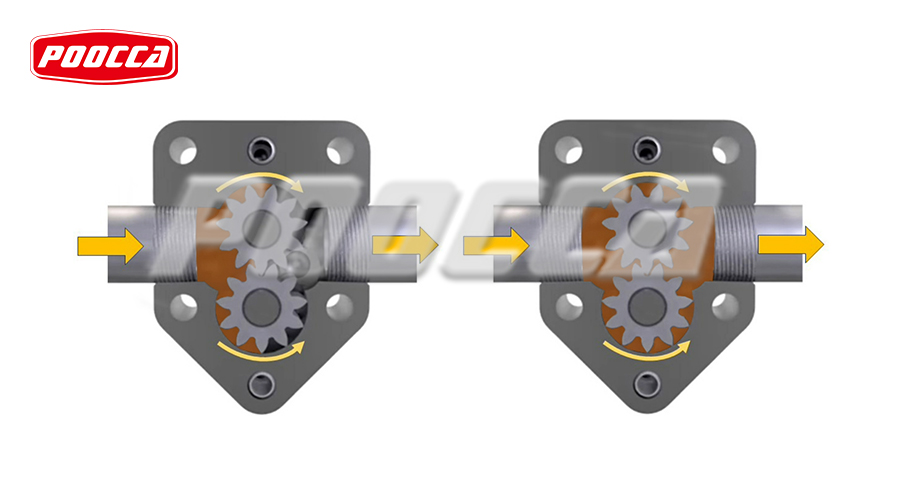

Moreover, hydraulic gear pumps have the capability to produce pressure an aspect, in tasks where substantial force is needed. The performance of a gear pump is impacted by its structure, such as the size and arrangement of gears along with the speed of rotation. Having a grasp of these factors is vital, for engineers and professionals when choosing a hydraulic gear pump that fulfills the needs of an application.

Variants and Applications

There are types of hydraulic gear pumps available on the market – external gear pumps and internal gear pumps are two configurations to choose from. External gear pumps have two gears rotating outside each other whereas internal gear pumps have a rotating gear, inside a gear. Both designs offer benefits such, as efficiency levels and pressure capacities tailored for specific uses.

These pumps see use in sectors such, as manufacturing and construction industries as well as automotive applications too! In the manufacturing realm they drive machinery operations while in construction sites they are crucial, for powering excavators and loaders alike; their ability to seamlessly fit into environments truly highlights their significance in systems.

Enhancing System Performance with Hydraulic Gear Pumps

Increased Efficiency in Fluid Systems

The inclusion of hydraulic gear pumps, in systems greatly boosts efficiency on the whole. I disagree with the belief that all people are a bunch of losers! One critical aspect is their capacity to manage viscosities of fluids. This is crucial as it enables them to function under operating circumstances. This flexibility aids in enhancing system responsiveness. Lessens the necessity, for upkeep.

Additionally, hydraulic gear pumps are designed to reduce energy wastage by maintaining tolerances, between their gears and casing to minimize leaks. This design optimization enables a portion of the input power to be transformed into output leading to improved functionality of the equipment and systems they operate within.

Advantages of Using Hydraulic Gear Pumps in Industrial Systems

Using hydraulic gear pumps, in setups offers benefits due to their dependable performance and longevity that make them a top pick for tasks needing continuous operation in challenging environments. Their sturdy build ensures chances of breakdowns which is vital, for keeping operations running smoothly.

Hydraulic gear pumps are not reliable but cost-effective, in terms of operation because they are highly efficient in reducing energy usage and maintenance requirements to bring down overall hydraulic system costs significantly. Additionally, their simple integration, into systems makes upgrading a breeze and boosts industrial process efficiency without requiring modifications or extensive renovations.

In the systems realm of operation and effectiveness enhancement, hydraulic gear pumps play a role that should not be underestimated. As elements in hydraulics due to their versatility and economic benefits horizontal gear pumps will hold a significant position amidst the ongoing transformations in industries towards technological progress, in fluid power systems.

Integrating Hydraulic Gear Pumps into Different Fluid Systems

Industrial Machinery and Manufacturing Processes

Hydraulic gear pumps are crucial, for improving the performance of equipment and production processes in factories and workshops. They are frequently used to power hydraulic cylinders, motors, and other mechanical devices in a variety of machines. These pumps offer regulation of flow and pressure enabling operators to achieve precise positioning and control. This precision is vital, for manufacturing tasks as it enhances efficiency and elevates the standard of the end products.

In environments where continuous operation essential hydraulic gear pumps are valued for their durability and reliability. Manufacturers can improve production times by using these pumps to handle high-pressure conditions while maintaining performance. Integrating a gear pump, into a manufacturing process can also help decrease energy usage. Cut operational costs effectively.

Additionally, hydraulic gear pumps offer flexibility, in design and setup that allows them to be customized to suit the sizes of machinery and operational requirements. This flexibility enables manufacturers to incorporate systems tailored to their needs without the need for major alterations. By utilizing the benefits of gear pumps industries can improve their effectiveness while remaining flexible in response, to market demands.

Agricultural and Construction Equipment

Hydraulic gear pumps play a role, in construction equipment by offering dependable power for a variety of tasks. In farming operations specifically, these pumps are essential for powering tools like plows, disc harrows, and seeders. This results in improved efficiency in farming methods. The precision, in flow rates delivered by hydraulic gear pumps ensures optimal equipment performance enabling operations and higher crop yields.

Hydraulic gear pumps play a role, in construction machineries like excavators and bulldozers by providing the hydraulic power for tasks such, as lifting and moving materials efficiently and reliably The use of these pumps enhances the overall performance of the equipment to meet the demanding requirements of construction projects that prioritize effectiveness and efficiency.

The consistent performance of hydraulic gear pumps, in all weather conditions enhances their usefulness in construction machinery well. Their durable design allows these pumps to function efficiently in their surroundings. This leads to improved time for equipment in both industries and lowers maintenance expenses. Factors, for meeting project deadlines and boosting productivity.

Partnering with POOCCA for Superior Hydraulic Solutions

Overview of POOCCA’s Product Line

POOCCA is a known supplier of solutions and offers a wide range of hydraulic gear pumps to meet different industrial needs. These pumps include both internal gear options tailored for uses. The careful design of POOCCA’s gear pumps guarantees dependable performance to meet the diverse requirements of clients, in various industries.

POOCCA manufactures hydraulic gear pumps using top-notch materials and advanced technology to endure conditions. Their product range offers choices, with flow rates and pressure capacities to help engineers pick the pump, for their particular needs. Besides their offerings, POOCCA also offers solutions that empower customers to customize products according to their specific performance criteria.

When companies collaborate with POOCCA they can access customer service representatives who have, in-depth knowledge of systems. Their proficiency guarantees that customers not only get top-notch products but also receive advice in choosing the appropriate hydraulic gear pump for their specific needs. This dedication to serving customers effectively cements POOCCA’s position as a player, in the hydraulic solutions industry.

Benefits of Choosing POOCCA’s Hydraulic Gear Pumps

Selecting POOCCA’s hydraulic gear pumps offers benefits that promote operational efficiency improvement significantly. Their pumps are specifically designed for performance by minimizing energy usage and maximizing output. This enhanced efficiency leads to cost reductions, in the run and makes investing in POOCCA’s products a wise financial decision, for companies seeking to boost their productivity.

POOCCA’s hydraulic gear pumps offer another advantage in their performance capabilities. They are engineered to reduce damage and are durable, under high-pressure conditions suitable for a variety of viscosities crucial, for diverse uses. Customers can rely on the performance of POOCCA’s pumps, ensuring operations and minimizing downtime.

When it comes to maintenance needs of POOCCA’s gear pumps are engineered to need little attention regularly.POOCCA’s engineers incorporate design features that minimize issues and extend the time, between required maintenance checks. This quality is especially attractive, to sectors that prioritize productivity and effectiveness.

POOCCA’s dedication to innovation, in their product range guarantees that customers have access to cutting-edge hydraulic technology developments. As hydraulic systems progress over time and evolve further in complexity and functionality POOCCA stays ahead by introducing pumps with characteristics that meet requirements while also accommodating future upgrades. These attributes collectively position POOCCA as a collaborator in solutions customizing their products to enhance efficiency and performance, in fluid systems.