Gear pumps are a common fluid transfer equipment. Due to the special characteristics of its working environment, gear pumps are prone to wear, leakage and other problems in the process of use, which in turn affects its normal operation and service life. Therefore, in order to ensure its long and stable operation, maintenance work is crucial, is to extend its service life of the key. The following are some of the gear pump maintenance of the popular science content, in order to provide useful reference for the majority of users, to help you correctly carry out maintenance operations.

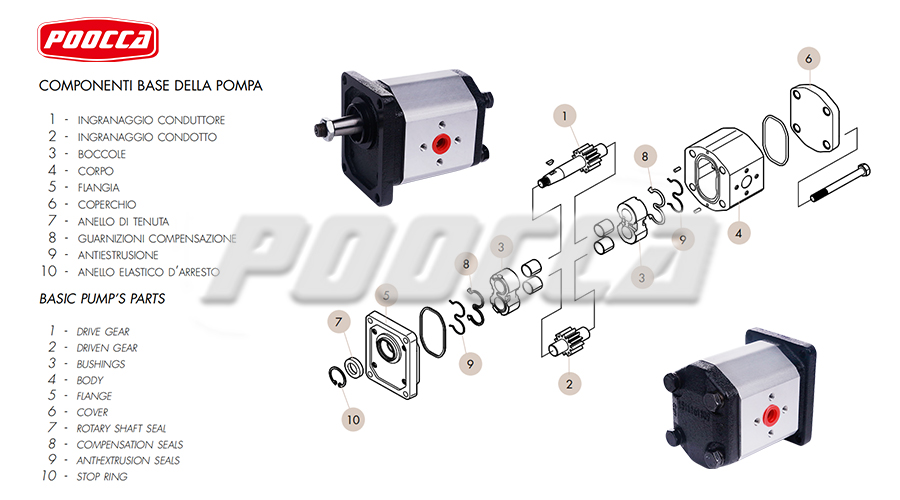

Basic structure and working principle of gear pumps

The basic structure of the gear pump is mainly composed of the active gear, driven gear, pump body, front and rear pump cover and safety valve. Its working principle is to rely on the mutual meshing of the two gears, so that the pump cavity in the working process gradually increase or decrease, so as to complete the function of suction and discharge of liquid.

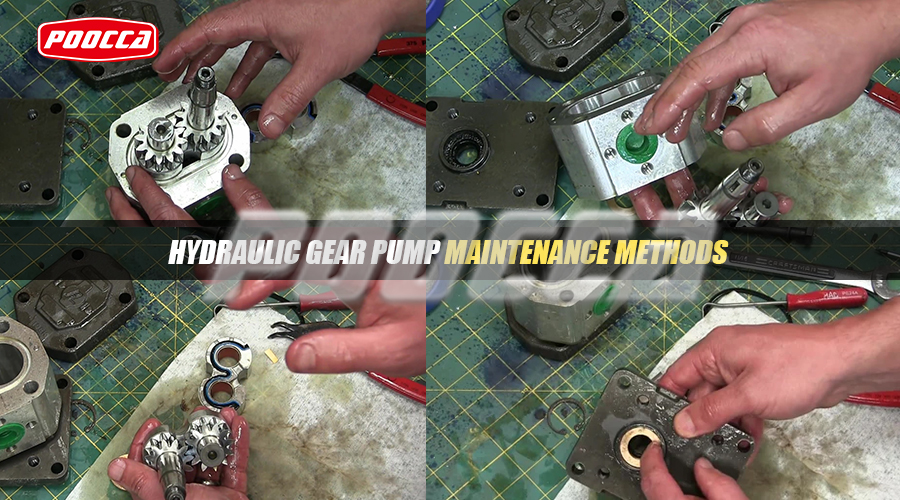

Maintenance of gear pumps

Regular inspection and cleaning

During the use of gear pumps, system flushing should be carried out regularly to remove the dirt and sediments in the system, which helps to maintain the efficient performance and prolong the service life of gear pumps. First of all, check whether the pump body, gears and seals and other components are intact, such as damage should be replaced in a timely manner. Secondly, clean the inside of the pump body to remove deposits, impurities, etc. to prevent blockage and wear. During the cleaning process, care should be taken not to use hard objects to scrape the inside of the pump body to avoid damaging the surface.

Lubrication and sealing

Normal operation of the gear pump depends on the effectiveness of the lubricant and seals. Regularly checking the cleanliness and viscosity of the lubricant will enable the lubrication system to work properly. Timely replacement of aged or contaminated lubricant, gears and bearings can be fully lubricated. Also, regularly check the seals of the gear pump, including oil seals and O-rings. The seals need to be intact to prevent oil leakage. Any worn, aged or damaged seals found should be replaced promptly.

Pay attention to vibration and noise

Abnormal vibration and noise can likewise reflect the condition of the gear pump. In daily use, attention needs to be paid to any abnormal vibration and noise, which may signal problems with bearings, gears or other components. Users can take steps to address abnormal vibration and noise to avoid damaging the equipment.

Maintenance of transmission parts

The transmission parts of the gear pump include bearings, bushings, etc. The maintenance of these parts is equally important. The wear and tear of the bearings should be checked regularly and replaced in time if there is any abnormality. Meanwhile, keep the shaft sleeve clean and lubricated to reduce wear and friction. When replacing transmission parts, attention should be paid to the correct installation position and direction to ensure the normal operation of the gear pump.

Inspection and adjustment of safety valve

The safety valve is an important protective device of the gear pump, used to prevent the internal pressure of the pump body from being too high. The sensitivity and reliability of the safety valve should be checked regularly, and if there is any abnormality, it should be adjusted or replaced in time. When adjusting the safety valve, the relevant operating procedures should be followed to ensure that the adjusted pressure value meets the equipment requirements.

Monitoring of operating parameters

During the operation of the gear pump, the working parameters of the gear pump should be regularly monitored, including flow, pressure and temperature. Keep the operating parameters within the normal range to ensure that the pump can work according to the design requirements. If abnormal fluctuations are found, the causes should be found and dealt with in time. At the same time, according to the working environment and load conditions of the equipment, adjust the operating parameters at the right time to ensure the stable operation of the gear pump.

These maintenance measures are the key steps to ensure the reliable operation of gear pumps for a long time. Through regular maintenance and inspection, the reliability of the equipment can be improved, thus reducing the problem of failure and downtime.

Gear pumps maintenance and maintenance notes

In the gear pump maintenance and repair, should ensure that the equipment is in a state of shutdown, and cut off the power supply to prevent accidents.

Use appropriate tools and materials for cleaning and maintenance, avoid using hard objects to scrape the inside of the pump body to avoid damage to the surface.

When replacing parts, select models and specifications that match the originals to ensure normal operation of the equipment.

When performing lubrication and sealing operations, care should be taken to keep clean and avoid impurities from entering the inside of the pump body.

Regular preventive maintenance of gear pumps, such as replacing lubricants, cleaning screens, etc., in order to extend their service life.

Conclusion

In summary, the maintenance and repair of the gear pump is the key to ensure its normal operation and extend its service life. Through regular maintenance and inspection, the reliability of the equipment can be improved, which can help reduce the failure and downtime. At the same time, it is important to pay attention to the precautions for maintenance and repair and follow the relevant operating procedures. Users should pay attention to the maintenance and repair of gear pumps, to provide a strong guarantee for the production and development of enterprises.

The main suppliers of POOCCA are gear pumps, piston pumps, motors, vane pumps, hydraulic valves, hydraulic cylinders and hydraulic accessories, and more hydraulic types. If you have any needs, please contact us and we will reply to you as soon as possible.