Understanding Poocca’s Gear Pumps

Overview of Poocca and Its Innovations

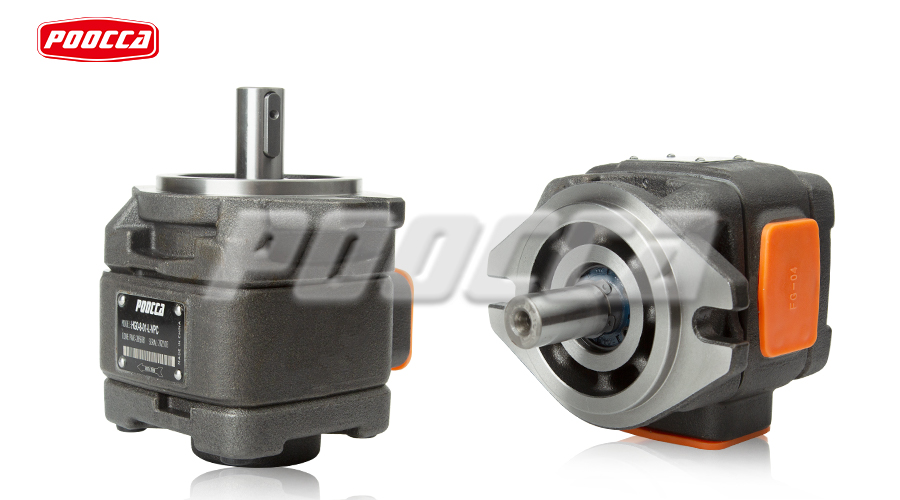

Poocca is a company that specializes in providing advanced pumping solutions for various industrial applications. With a commitment to innovation, Poocca has developed a range of gear pumps that excel in efficiency and reliability. These gear pumps are designed to meet the specific needs of different industries, including oil and gas, chemical processing, and more. By focusing on quality and performance, Poocca continues to lead the market in pump technology.

Features of Poocca‘s Gear Pumps

Poocca’s gear pumps are built with precision engineering to ensure optimal performance under varying conditions. These pumps feature robust construction, allowing for high tolerance against wear and tear. Furthermore, they promote a smooth flow of fluids with minimal pulsation, enhancing their suitability for sensitive applications. The compact design of Poocca’s gear pumps also facilitates easy installation and maintenance, making them a preferred choice among engineers and operators.

Basics of Gear Pumps

How Gear Pumps Function

Gear pumps operate on a simple principle: the rotation of gears creates a vacuum that draws in fluid and subsequently pushes it out. The gears mesh seamlessly, ensuring a continuous flow of liquid. This design provides a consistent discharge rate, making gear pumps ideal for transferring various fluids, including viscous materials. Additionally, they can handle different pressures, which contributes to their versatility across applications.

Types of Gear Pumps

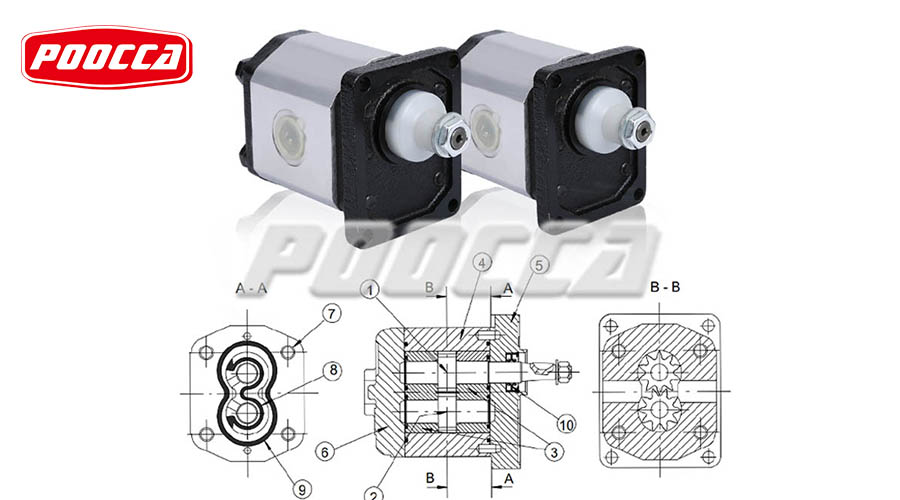

External Gear Pumps

External gear pumps consist of two external gears that mesh to perform the pumping action. The rotation of the gears creates a chamber that fills with fluid and then displaces it when the gears turn. This type of gear pump is highly efficient for transferring low to medium viscosity fluids and is commonly used in hydraulic systems.

Internal Gear Pumps

Internal gear pumps feature an internal gear that rotates within an outer gear. This configuration allows for the pumping of thicker fluids, making them suitable for more viscous applications. Internal gear pumps can also operate smoothly at varying speeds, which enhances their adaptability for different operational requirements.

Basics of Reciprocating Pumps

How Reciprocating Pumps Function

Reciprocating pumps operate by using a back-and-forth motion to displace liquid. The pump’s piston or plunger moves inside a cylinder, creating a vacuum that draws in fluid during the intake stroke. During the discharge stroke, the liquid is pushed out under pressure. This pulsating action enables reciprocating pumps to maintain a steady flow, but they can be less efficient than gear pumps when handling highly viscous fluids or requiring continuous flow.

Types of Reciprocating Pumps

Piston Pumps

Piston pumps employ one or more pistons to create the movement of fluids. As the piston moves, it generates suction, pulling fluid into the pump chamber. Piston pumps are suitable for high-pressure applications and can handle a variety of fluids, making them useful in sectors like water treatment and oil extraction.

Plunger Pumps

Plunger pumps use a plunger to move fluid, increasing pressure for high-pressure discharge. They’re ideal for high resistance and pressure applications like hydraulic systems and chemical processing.

Understanding gear and reciprocating pumps is key for choosing the right equipment. Gear pumps offer continuous flow and efficiency, especially with viscous materials. Reciprocating pumps create high pressure but may not perform as well in some conditions. Poocca’s innovative gear pumps highlight the importance of selecting the right pump for your needs.

Key Differences Between Gear Pumps and Reciprocating Pumps

Mechanism and Operation Differences

The fundamental operational differences between gear pumps and reciprocating pumps lie in their mechanisms. Gear pumps utilize the meshing of gears to create a continuous flow of liquid. As the gears rotate, they create a void that draws fluid into the pump, which is then pushed out through the discharge port. This mechanism results in a smooth, pulsation-free flow, making gear pumps well-suited for applications requiring consistency in fluid transfer.

In contrast, reciprocating pumps operate using a back-and-forth motion of a piston or plunger within a cylinder. During the intake stroke, the movement generates a vacuum that draws fluid into the chamber. Conversely, during the discharge stroke, the fluid is expelled under pressure. This action leads to a pulsating flow characteristic of reciprocating pumps, which may pose challenges in applications where a steady flow is needed. Understanding these differences is essential in selecting the appropriate pump type for specific tasks.

Efficiency and Performance Comparison

When comparing the efficiency and performance of gear pumps and reciprocating pumps, there are notable distinctions that impact their usage in various industries. Gear pumps typically exhibit higher efficiency when handling viscous fluids due to their design that maintains a consistent flow rate. As a result, they can operate effectively under varying loads, making them a preferred choice in industrial applications where viscosity is a factor.

On the other hand, while reciprocating pumps are capable of generating high pressures and can handle a wide range of fluid densities, their efficiency may decline with increasing viscosity. The pulsating nature of their operation can lead to pressure fluctuations, which may affect the overall performance in applications requiring stable flow rates. Thus, the selection between a gear pump and a reciprocating pump is often influenced by the specific requirements of the fluid and the application context.

Suitable Applications for Each Pump Type

Gear pumps are widely used for continuous flow of high-viscosity fluids in industries like food processing, chemical manufacturing, and petroleum transportation due to their reliability and performance. They provide a uniform flow rate, reducing product damage, making them ideal for sensitive applications.

Reciprocating pumps are essential where pressure is critical, such as in water treatment and oil extraction. They offer controlled discharge rates and high pressure, adaptable to various fluids but may need modifications for optimal viscosity handling. Choosing the right pump based on operational needs is crucial.

Advantages of Using Poocca’s Gear Pumps over Reciprocating Pumps

Poocca’s gear pumps present several advantages over traditional reciprocating pumps that enhance efficiency and operational ease. The foremost benefit lies in their consistent flow output, which significantly reduces the risk of pressure fluctuations associated with reciprocating pumps. This characteristic promotes enhanced stability in fluid transfer and is particularly crucial in processes where accuracy and consistency are paramount.

Additionally, Poocca’s gear pumps are designed with robust materials that provide durability and resistance to wear, making them ideal for long-term use in demanding environments. Their compact design not only optimizes installation processes but also simplifies maintenance, thereby minimizing downtime in industrial operations. Furthermore, the versatility of these gear pumps allows for compatibility with a wide range of liquids, including corrosive and abrasive fluids, which expands their applicability across diverse sectors.

Choosing the Right Pump for Your Needs with Poocca’s Expertise

Selecting the right pump involves considering fluid properties, operational needs, and efficiency. Poocca’s expertise helps industries find suitable equipment. Their team evaluates each application to ensure businesses get the best pump.

Poocca guides clients in choosing between gear and reciprocating pumps, focusing on customization for optimal performance and reliability. Leveraging Poocca’s insights, companies can address fluid transfer challenges and benefit from efficient gear pumps.

Understanding gear and reciprocating pumps is crucial for informed choices. By considering operational mechanisms, efficiency, applications, and Poocca’s solutions, industries can enhance performance and productivity. Choosing the right pump is a strategic decision impacting overall success.