Understanding Gear Pumps

Gear Pumps: Meaning & Type

Gear pumps belong to a family of positive displacement rotary machines which use rotating gears to move fluid. Gear pumps operate by trapping a fluid in the space between the helical gear teeth and pump casing, forcing it around meshing or engaged gears to now have max pressure at discharge. These pumps are reputed to handle a broad spectrum of liquids including more viscous fluids such as cooking oil. These characteristics make them an attractive option for several industrial uses.

Typical Uses of Gear Pumps

The gear pumps find a place in everyday lives and wide range of industries like chemical processing, oil & gas, food production etc. They are great when transferring creamy liquids, oils, paints and adhesives. They have uses in hydraulic systems that need a steady flow of fluid. Gear Pumps are essential in manufacturing & processing environments due to their versatility.

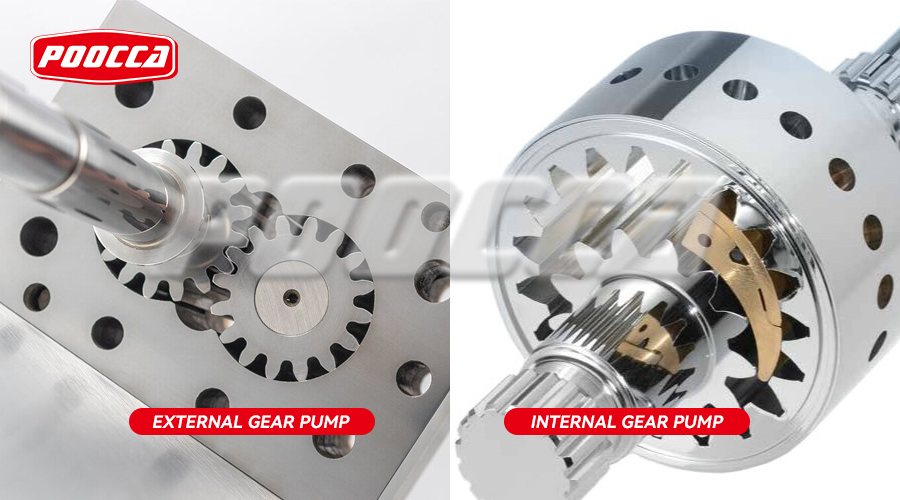

External VS Internal Gear pump

Differences in Design & Structure

External and internal gear pumps differ primarily in their design. Outer gear pumps incorporate a few gears that pivot corresponding ways in an epitaxial organization. This design is market-leading in facilitating effective fluid movement and generates higher flow rates. Internal gear pumps, on the other hand, have a smaller primary gear that rotates within a larger stationary map making them ideal in areas where space is an issue.

External Gear Pump Features

External gear pumps are generally known for their simplicity and reliability. This usually results in reduced chance of failures overall, with low maintenance costs. It is quite uncomplicated to set up and operate the external gear pumps. In addition, they have the ability to process a wide range of fluids and are used in many applications.

Internal Gear Pump Features

Internal gear pumps will work on the same principle as above but designed to handle more viscous type fluids and with less shear and turbulence. One of the advantages this design offers is that with especially sensitive materials, it allows you to process such things whilst still maintaining their structure. Because internal gear pumps are some of the quietest options available, they excel in applications that need noise control.

Functional Differences in Functioning

At this functional point, an external gear pump can absorb a higher flow rate and are usually used in applications requiring fast fluid transfer. The same valves may not be as effective when managing fluids with different viscosities. On the other hand, internal gear pumps include better performance in handling thicker liquids which makes it a versatile pump for various operational conditions. These functional differences can help users to decide which pump would be best for the application they need.

Pros of External Gear Pumps

Efficiency and Performance

External gear pumps can offer a high level of efficiency, especially in situations where required flow rates must remain constant. Simple construction of this type means there is minimal loss and more efficient operation. Their superior performance makes them a preferred option in industrial areas where transfer of fluids rapidly is crucial.

Maintenance and Durability

One more main benefit of an external gear pump is their longevity and straightforward maintenance effort. Since there are fewer moving parts involved with PD pumps, the chances of wear and tear occurring reduces quite a bit — meaning these will be able to last longer before operational life begins to shorten. Simpler to maintain, leading to far less downtime and in turn costs. External gear pumps from reputed brands like Poocca are superior quality, made for a long life run and deliver the best performance.

Application Scenarios

The external gear pumps are used in applications that have heavy duty fluid transfer use case such as the chemical manufacturing or oil and gas extraction. Since they can handle liquids (even for those with particulate matter) this makes them great in difficult environments. External gear pumps are often prized by industries in pursuit of reliable and efficient solutions.

Benefits of Internal Gear Pumps

Handling of Viscous Fluids Is Efficient.

One of the biggest advantages to an internal gear pump is how well it handles viscous fluids. This makes them especially well at pumping products such as molten polymers and heavy oils without breaking these substances. This increases the performance and also expands its processable material range.

Noise and Vibration Reduction

Most notably, an advantage of internal gear pumps is that they operate more quietly than external gear pumps. Its internal design reduces vibrations, automatically resulting in a less turbulent and quieter operational ride. This is especially nice in environments like food processing where white noise would cut down on a nicer working environment.

Application Scenarios

These are the pumps that use an internal gear mechanism, and these types of gears generally provide a controlled flow rate like in systems in which one must handle viscous fluids. These pumps are often used in industries such as food & beverage, paint & coatings and pharmaceuticals where cleanliness is paramount when transferring fluids. They are universal and hence, applicable in a range of operational backgrounds spanning different sectors.

How To Pick The Right Pump For You

Poocca External Gear Pump: Models and Advantages

Poocca designs its external gear pumps for longevity and peak flow performance, with a variety to choose from. Being type of versatile pumps, and these are known worldwide for their excellent flow rates and long life that making ideal choices to move a wide variety of industrial fluids. Their developed simplicity limits the possible break points, bringing about less maintenance and lower operational costs.

External gear pumps: The design of the external gear pump by Poocca enables it to efficiently work with changing viscosity fluids, which is very useful in environments like oil extraction or chemical manufacturing. In addition, their simple set-up reduces business training time and facilitates easy integration into existing workflows. After all, the dependability is one of those external gear pumps that you can trust to work when you need them to – and approaching its own unique form of quality comes from a company already known for creating a global benchmark in both wear lifespan and pumping efficiency.

Poocca Internal Gear Pump- Introduction and Advantages

By comparison, Poocca’s internal gear pump offering are a great solution for applications that need to tightly control flow rates and handle materials with high viscosities. They also operate with very low shear and turbulence, which helps to maintain the purity of delicate liquids. This is especially valuable in industries such as food processing where keeping product quality consistent and high can be extremely important.

The company also noted that Poocca’s internal gear pumps operate quietly because of the design, which minimizes vibrations. This not just provide a happier work area as well maintain a seamless and steady operation going on. Perfect to transport (high-density) heavy oils, coatings or polymers these pumps are central tool for high value and top performance industries.

Poocca: quality at all costs

Poocca brand values Summary

Central to its mission, Poocca is dedicated to creating an extraordinary experience for all their customers by means of a fresh outlook and ground-breaking ideas. In addition to local design and competitive pricing, Poocca sells the idea that each product is reliable, well-crafted, assembled with care in their own facility by experts, and energy-efficient. Always investing in research and development, Poocca is committed to equipping its gear pumps with the newest technology according to strict industry standards. Their commitment to excellence delivers performance advantages in their products and ensures that customers receive long-lasting pumps made for the demands of an industrial setting.

Another important part of the brand values that Poocca is transmitting to the world corresponds with customer service. The company insists on After-Service, where they want to develop long-term relationships with its clients from purchase point to customer support. Poocca also employ knowledgeable staff meaning customers can get the assistance they need to help them select their pumps as well as address any technical queries ensuring customer satisfaction remains top of Pooccas agenda.

Warranty and Support Services

Poocca backs its products with comprehensive warranty and support services to guarantee a customer-friendly investment. A warranty is available on each pump and covers defects in workmanship or material failure resulting from normal operation. This guarantee is indicating the Standard and confidence of Poocca gear pumps, they are construct to work at the best level years Back.

Poocca is also backed by a wide range of support services, including technical and ongoing maintenance assistance in addition to the warranty coverage. When problems do arise, support teams can provide resolution strategies that reduce downtime and keep things running as planned. This type of advanced customer support is crucial for helping users to get as much use out of their air operated diaphragm pumps as possible, and also ensures any problems are effectively addressed.