Basic Vane Pumps Explained

What Is a Vane Pump?

The vane pump is designed to be a positive displacement, using mounted Vanes on the rotor that radially lift and pressurize the fluid. It means there can be a flow of liquid but not make only in one direction without interruption which makes it for hydraulic applications. Vane pumps offer a high level of reliability and ease of maintenance, which make them ideally suited for use in many different operational environments. Commonly used in industrial and mobile equipment, they are developed for applications such as material handling to hydraulic machinery.

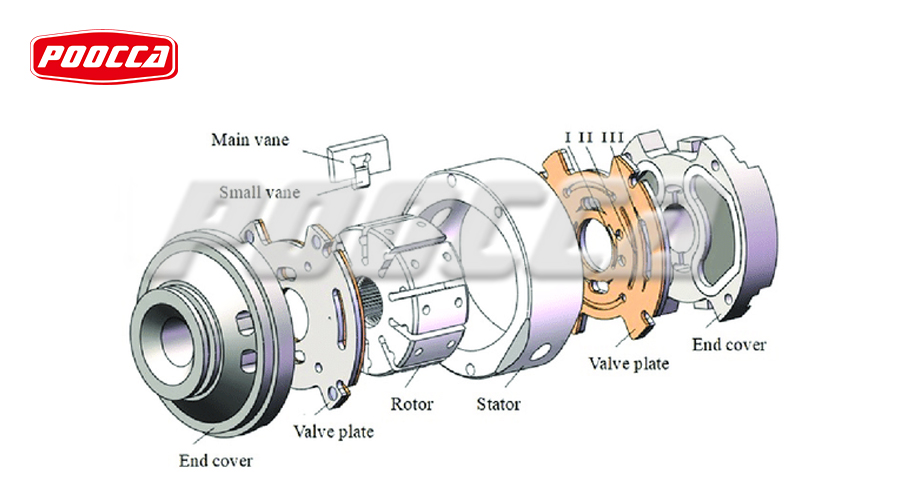

Key Components of a Vane Pump

Some of the key elements that can be found in a vane pump are: rotor vans, stator, suction and discharge ports, and a housing. The rotor is the center portion of the pump that rotates inside a die cast aluminum housing with vanes extending from its slots to form pumping chambers. The stator surrounding the rotor and clearance are given to work on vanes properly. These parts work together to create vacuum and discharge suction for proper function.

Types of Vane Pumps

They come in many models but for the most part they are fixed or variable displacement pumps. Fixed displacement vane pumps – The Vickers VQ Series offers stable flow output which makes it ideal for processes that require consistent conveyance of fluid. Variable Displacement Vane Pumps, such as the Parker T6 Series can change its displacement to meet the needs of demand and is ideal for more versatile hydraulic systems. There are various kinds of pumps each with their unique requirements and they serve the best for some niche applications based on industry demands.

How Does a Vane Pump Work?

The Working Mechanism

The vane pump working can be understood with the diagrammatic representation of rotor and vanes. When the rotor spins, centrifugal force carries vanes outward against the inner surface of a stator to form sealed chambers that enlarge and shrink. This compressulates the fluid in a following chamber and then squeezifies it out through an exhaust port. This design provides virtually pulse-less flow and delivers the high speed capabilities of gear pumps while still being a good pick for many common vane pump applications.

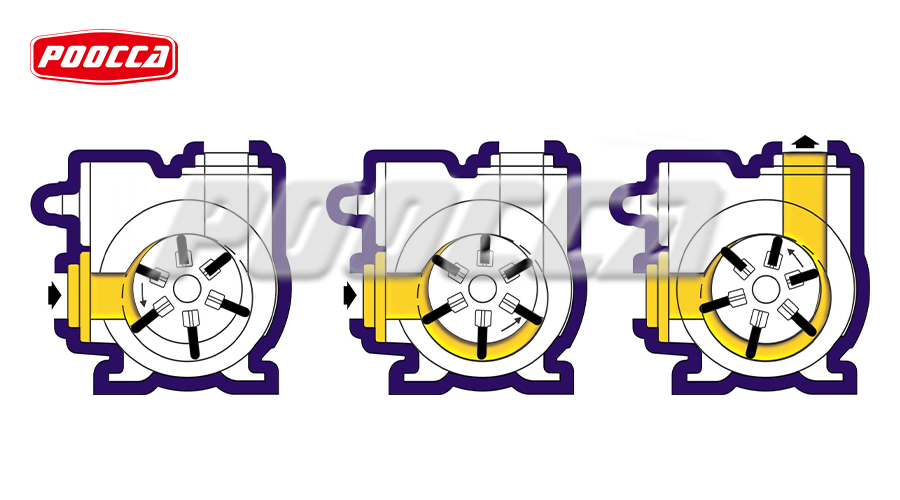

Vane Pump Operation Cycle

A vane pump is operated in three stages, suction, compression and discharge phases. it is important to know these phases in order to understand how the vane pump working efficiently during its operation.

Suction Phase

As the rotor turns, a suction-pressure area is formed by rotation of the blade on pump chamber. This low-pressure zone permits the fluid to be drawn into from a reservoir through suction port. The movement of the vane outward allows fluid into the pump to be efficiently drawn totally in. The layout makes the process of drawing in easier which is key to a good influx and also helped avoid cavitation.

Compression Phase

After the suction phase, you have this compression stage where now some of its rotational force here is pushing your trapped fluid down into a smaller chamber. With the reduction in volume of chamber, pressure of the fluid also increases. The given pressurization is especially when needed for systems where fluid needs to be moved against a high resistance or over long distance. The fast and reliable arrival of the liquid by means of an efficient compression.

Discharge Phase

The fluid is then forced out of the pressure port to an external system through a valve in the discharge phase. Such is performed through the continuous rotation of the rotor, thus retaining this elastic cycle for fluid to move. The ability to move fluid into hydraulic systems, or other equipment requiring a continuous supply is crucial during this phase. This phase demonstrated the effectiveness of vane pump decreasing pressure loss and increasing flow rates.

Vane Pump Application and Advantages

Common Applications

The vane pumps are suitable for low- to medium-pressure applications and find use in hydraulic machinery, automotive systems, transmissions as well industrial processing equipment. When it comes to hydraulic systems that need accurate and repeatable control over variable flow rates or pressures, for example, the Vickers VQ series vane pumps provide an ideal solution. Accordingly, site of application has mainly been in high pressure and volumetric efficiency demanding hydraulic systems with the Parker T6 series being used. These examples showcase the adaptability of vane pumps in a variety of utilizations.

Benefits of vane pump

There are many advantages of using vane pumps. Applications requiring extremely consistent fluid flows are also well suited for this form of rigid diaphragm pump, which limits interference and pulsation. Volumetric efficiency in the Parker T6 series and similar pumps is also high, limiting waste while quenching thirst to produce power. Additionally, many Vane pump-styles — New or otherwise … like the characteristic of being quiet in operation, which is a big benefit complete with noise reduction environments. Furthermore, vane pumps are capable of withstanding pressures as high as 275 bar and can be used for extreme duty applications.

In summary, the more you know about how a vane pump works in general, the better prepared of an operator or designer you can be for fluid power applications! Understanding the basic building blocks and operational cycles of vane pumps will give you some further insights, allowing a better understanding to why they are such system wide spread applications as well as their benefits. Regardless of the specific use case — be it in hydraulic systems for industrial applications or mobile machinery — vane pumps are still an indispensable piece of contemporary engineering.

Introduction to Poocca and Product Overview

Poocca: A Name Of Trust In Hydraulic Solutions

As a trusted name in the field of hydraulic solutions, Poocca is truly judged as one of premium brand providing durable components which will go well with to any sort regular or expert working on liquid business. Poocca designs its pumps with performance, reliability and efficiency in mind; building everything from the ground up – taking five steps forward instead of two. Their commitment to prestige manufacturing guarantees that their items will survive the harsh circumstances unique to hydraulic systems, making it a preferred choice for engineers and operators alike.

The brand puts in efforts and resources into research & development, to deliver pumps that truly reflect the essence of incorporating advanced technologies along with ease-of-use features. The robust performance of Poocca distinguishes it from competing products which do not guarantee the designed life and efficiency, making hydraulic application work in just about every sector such as automotive, construction & industrial manufacturing.

Showcasing Poocca’s Vane Pump Series

The company’s vane pump line comprises solutions for nearly every hydraulic application, with fixed displacement and variable displacement styles available from Poocca. Their models address low, medium and high pressure requirements which means that they are applicable for use across a wide range of environments. Designed for high efficiency and low noise, the vane pumps are perfect in environments where operational noise is disruptive.

This, for instance with the Poocca Vickers VQ Series provides a wide range of flow-rates making it ideal for both industrial machinery and mobile applications. At the same time, the Parker T6 series offers high volumetric efficiency which helps to reduce energy consumption in an ideal range as well. With every model designed by Poocca, performance is assured to be constant and long-lasting.