Understanding Directional Valves and Their Functions

Basic Principles of Directional Valves

Directional valves are critical components in hydraulic systems that control the flow direction of hydraulic fluid. They offer guidance for the movement of the fluid, determining the path it takes to perform various functions in a hydraulic circuit. The operation of directional valves is primarily based on the position of their internal components, which either allow or restrict fluid flow. This ability to control flow direction ensures that different hydraulic actuators, such as cylinders and motors, can be operated efficiently according to specific operational requirements.

Types and Classifications of Directional Valves

Different types of valves can be categorized based not only on their setup and purpose but also on their design and how they operate –poppet valves are great for simply turning flow off or allowing it through depending on where they are placed; spool valves are more flexible and come in handy for setups needing different channels, for flow; and rotary valves that usually work with rotary actuators. Furthermore, the categorization can also depend on the number of positions and methods that determine the number of flow routes the valve can manage and the variety of conditions it can reach.

Key Components and Mechanisms

Directional valves consist of parts, like the valve body that contains components and fluid passages; the spool that controls the flow of the hydraulic fluid by sliding or rotating; actuators such as manual levers or solenoids responsible for moving the spool; and crucial seals, for preventing fluid leaks and maintaining a sealed and effective system. It’s vital to grasp how these parts work together to enhance their efficiency within a system.

Impact of Directional Valves on Energy Efficiency

Energy Loss Minimization Through Efficient Valve Design

Directional valves play a role, in enhancing the energy efficiency of systems by reducing energy losses caused by leakage and internal friction through the optimized design of valve components, in terms of shape and size to minimize pressure drops and decrease energy consumption in the system Manufacturers have recognized the benefits of improving sealing technologies to reduce leakage and achieve cost savings in hydraulic applications overall.

Role of Actuation Methods in Energy Consumption

How a directional valve is operated can have an impact, on energy usage levels in systems. The use of actuation is becoming more popular in hydraulic setups because it enables precise control and quick response times that ultimately lead to lower energy consumption. Pneumatic actuation techniques can also offer efficiency advantages depending on the circumstances. When deciding on how to actuate valves it’s crucial to assess system requirements and make sure that your chosen method aligns with your energy-saving objectives, for the application.

Comparative Analysis with Other Hydraulic Components

When looking at energy efficiency in systems it’s important to consider how directional valves stack up against pumps and actuators. Directional valves are crucial, for managing flow and direction. It’s the synergy, with pumps and hydraulic motors that truly impacts energy efficiency. A tuned hydraulic setup will feature components that cooperate seamlessly resulting in energy usage and peak performance. Incorporating valves can boost the overall performance of the hydraulic system and lead to notable energy conservation and decreased emissions.

Technological Advancements in Directional Valves

Innovations in Valve Materials to Improve Efficiency

Advancements, in material science, have brought about progress in the production of valves by integrating lightweight and strong materials to reduce valve weight without compromising durability and reliability. The incorporation of composite and advanced polymer materials can enhance the sealing capabilities of valves decreasing leakage and boosting energy efficiency. These material developments do not enhance performance. Also prolong the lifespan of components, in challenging hydraulic settings.

Smart Control Systems and Their Integration

The emergence of control systems has revolutionized the way directional valves function nowadays. These systems make use of sensors and automated mechanisms to oversee movement and regulate the valve’s location instantly. This improves the speed and effectiveness of systems. Smart technologies help, in conserving energy by ensuring that the hydraulic system functions when necessary and reduces power consumption. By incorporating technologies there is now access to diagnostic tools and monitoring capabilities offering essential insights that can be utilized to bolster efforts, toward energy conservation.

Predictive Maintenance and Its Benefits

Anticipatory servicing is gaining importance in overseeing the functionality of valves, in setups nowadays More and more engineers leverage data analysis and sophisticated monitoring instruments to anticipate maintenance requirements ahead of any breakdowns This forward-looking strategy reduces downtime and extends the lifespan of the directional valves resulting in improved energy efficiency The advantages encompass decreased energy usage reduced operational expenses and heightened dependability of hydraulic systems engaging in maintenance plays a role, in maintaining energy efficient processes and supports the overall objectives of reducing environmental footprint and enhancing productivity, within the organization.

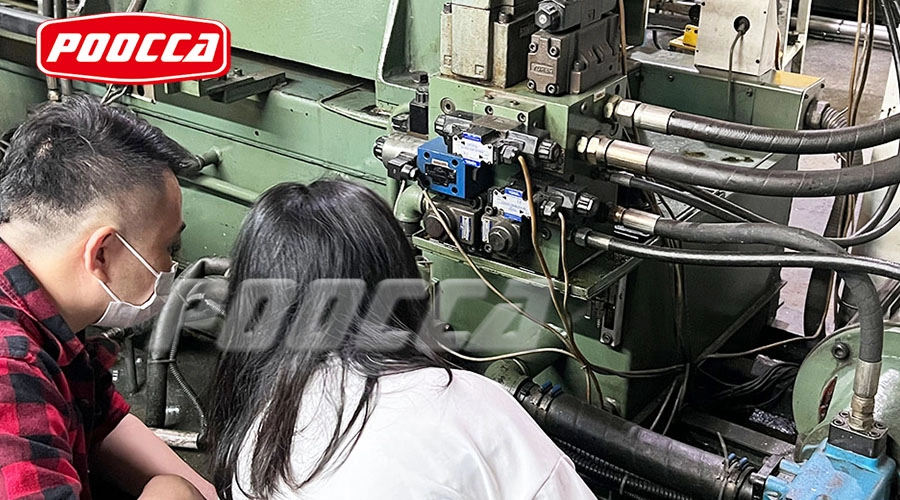

POAOCCA’s Contribution to Energy-Efficient Directional Valves

Overview of POOCCA Products for Energy-Saving

POOCCA plays a role, in the hydraulics industry by focusing on creating valves that prioritize energy efficiency in their design process. The company’s range of products highlights approaches that help lower energy consumption in settings. POOCCA’s directional valves showcase designs that improve performance and reduce energy loss in systems. Through the use of technology and friendly materials alongside intelligent control systems, within their offerings, POOCCA actively promotes sustainability by emphasizing energy-efficient methods.

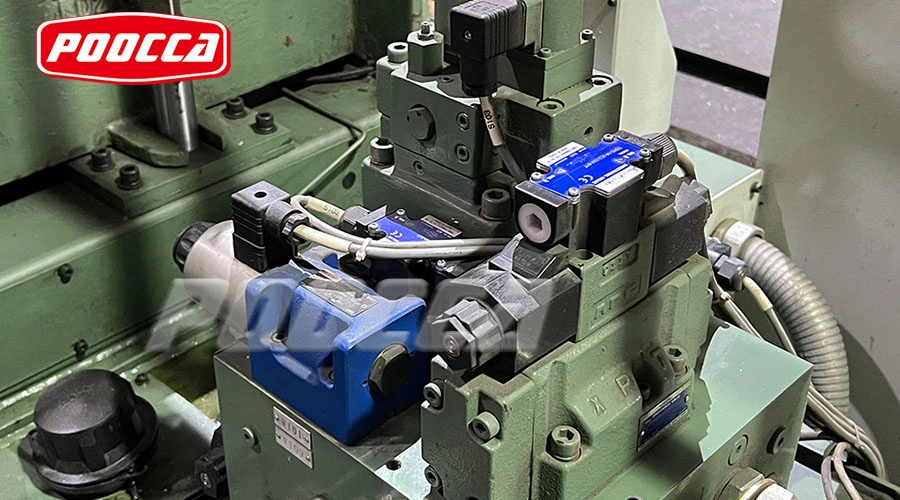

Product-Specific Features Promoting Efficiency

POOCCA’s directional valves come with a range of features designed to enhance energy efficiency and optimize system performance. One key feature is the integration of top-notch sealing materials that greatly reduce leakage rates—a source of energy waste, in setups. Moreover, the innovative spool designs in POOCCA valves enable the operation and less flow resistance resulting in lower pressure drops, across the system. Additionally, their products work with activation methods, like pneumatic systems giving users options to choose the most effective operating mode based on their energy-saving objectives.

Application Areas and Real-World Benefits

Industrial Energy Savings through Optimized Valve Systems

In environments, like manufacturing and construction sectors using directional valves to optimize hydraulic systems has been shown to save a significant amount of energy over time which leads to lower operating expenses and increased productivity levels for these industries by offering better control over fluid flow rates using efficient valve designs from POOCCA that can be customized for improved system performance, with less energy consumption resulting in both economic and environmental advantages.

Agricultural Machinery Enhancements Using Advanced Valves

In farming settings nowadays¸ energy-efficient directional valves are playing a role, in enhancing the sustainability of practices by reducing fuel usage without compromising performance levels for vehicles like tractors and harvesters equipped with these advanced valves¸ enabling more precise control over hydraulic functions for improved execution of farm tasks¸ and when used alongside equipment such as seeders and sprayers¸ they can also contribute to lower emissions and adherence to environmental rules, for a greener agriculture industry.

Benefits in Commercial HVAC Systems and Renewable Energy Sectors

Directional valves are crucial, for improving the energy efficiency of HVAC systems by regulating fluid flow to maintain optimal thermal control for energy-efficient environments. They are also key in maximizing the effectiveness of systems in energy applications such as hydroelectric and wind turbine setups, for efficient energy transfer. By allowing for movements to take place smoothly and efficiently in machinery systems directional valves play a role, in promoting energy efficiency and emission reduction aligning with the current focus, on environmental sustainability.

Future Trends and Considerations

Emerging Technologies in Hydraulic Systems

The upcoming advancements, in systems, are poised to transform the functionality and energy efficiency of valves through the utilization of cutting-edge technologies This includes the incorporation of microelectromechanical systems (MEMS) which could bring about a significant shift in valve operation by enabling more streamlined designs, with improved precision control capabilities Furthermore AI and machine learning progress might enable predictive analysis integration allowing systems to autonomously optimize operations using real-time data metrics. This progress is expected to result in valves that save energy and can adjust to changing demand conditions in systems effectively.

Regulatory Impacts on the Development and Implementation of Directional Valves

As concerns about climate change and energy consumption continue to grow, regulatory frameworks are expected to influence the design and implementation of directional valves. Stricter guidelines aimed at reducing emissions and enhancing energy efficiency will push manufacturers to innovate continuously. Compliance with these regulations will require the adoption of advanced technologies and materials that not only meet performance standards but also align with sustainability goals. Consequently, players in the industry will need to remain agile, adjusting their designs and operational practices to adhere to evolving regulatory environments while continuing to deliver value to their customers.

In conclusion, the role of directional valves in energy-saving efforts cannot be understated. Their capability to control hydraulic fluid flow efficiently directly impacts the energy consumption of various applications, from industrial systems to agricultural machinery and HVAC setups. By focusing on advanced designs, smart technologies, and adherence to emerging regulations, stakeholders can leverage directional valves to foster a more sustainable future, ensuring both economic and environmental gains.