Understanding Variable Displacement Pumps

Variable displacement pumps are a crucial component in hydraulic systems, providing controlled fluid movement tailored to specific operational requirements. Unlike fixed displacement pumps, variable displacement pumps can adjust their output flow rate based on the system’s demands. This adaptability allows for increased efficiency in fluid management, reducing energy consumption while meeting performance criteria. Understanding the mechanics and applications of variable displacement pumps can significantly enhance operational efficiencies across various industrial sectors.

How Variable Displacement Pumps Work

Variable displacement pumps work, by changing the discharge volume size through mechanisms, inside the pump itself. These pumps utilize a flexible swash plate or a comparable design to modify the angle of the rotating components. This adjustment enables them to regulate the amount of fluid delivered per cycle accurately. Such adaptability helps systems function efficiently by providing the right amount of fluid as needed in real-time thereby maximizing performance and energy efficiency. Furthermore, incorporating controls can boost their ability to respond effectively to changing circumstances.

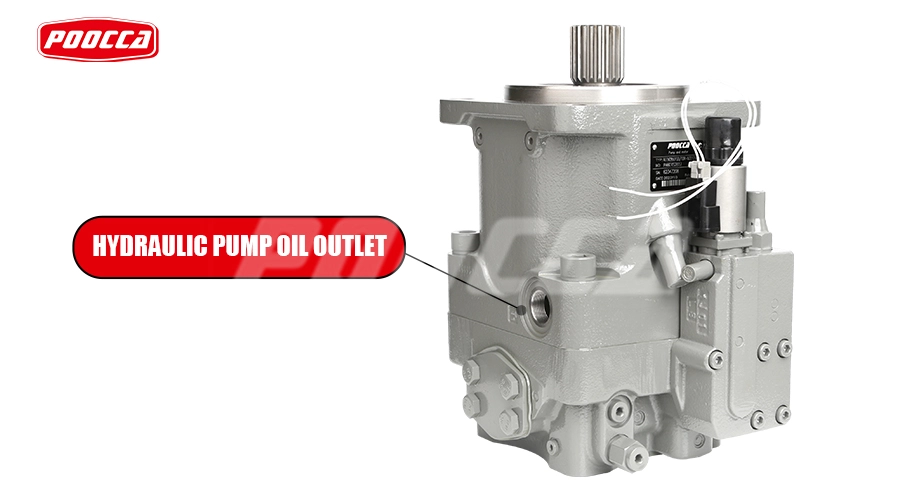

Key Components of Variable Displacement Pumps

Essential parts of a displacement pump consist of the housing, rotor, tilt plate, and operating mechanisms. The rotor plays a role, in movement while the angle of the tilt plate influences the pump’s displacement properties. Furthermore, the control system— hydraulic or electronic—is instrumental, in regulating the performance of the pump based on the system’s requirements. These elements collaborate to guarantee dependability and effectiveness establishing displacement pumps as a component of contemporary hydraulic systems.

Types of Variable Displacement Pumps

There are kinds of displacement pumps such, as axial piston pumps and radial piston pumps as well as bent axis pumps available in the market today each with its own set of benefits depending upon the size of the application and the nature of the fluid being used Axial piston pumps are known for their ability to handle high-pressure situations while radial piston pumps are favored for their compact size and efficiency Bent axis pumps excel in operations requiring high-speed performance Having a good grasp of these pump types is essential in choosing the right variable displacement pump, for specific needs.

The Purpose of Variable Displacement Pumps

Efficient Fluid Management

Variable displacement pumps serve to optimize control in systems by regulating their flow rate effectively to minimize fluid loss and maximize resource utilization efficiently. This function is especially crucial, in systems requiring management of pressure and flow rates to ensure safety and reliability by alleviating potential risks of excessive pressure buildup.

Versatility in Industrial Applications

Variable displacement pumps have a range of uses, in industries such as construction and agriculture due to their flexibility in various conditions and tasks like powering machinery or managing hydraulic systems in vehicles. This versatility enables companies to use a pump model for purposes that help in cutting down inventory and training requirements while enhancing efficiency, in various operational settings.

Enhancing System Performance

By offering management of flow rates, in hydraulic systems variable displacement pumps greatly boost operational efficiency. They ensure smoother functioning by sustaining flow levels, crucial in settings like manufacturing and energy generation. Moreover, they play a role, in diminishing the strain and degradation of system parts thus promoting longevity and dependability. Consequently, businesses that make use of displacement pumps frequently experience enhanced system performance. Minimized periods of inactivity.

Benefits of Variable Displacement Pumps

Energy Savings and Efficiency

Variable displacement pumps play a role, in enhancing energy efficiency in systems by adapting their output based on real-time needs to operate at lower power levels when demand is low – leading to decreased energy usage and cost savings for companies in the long run since energy expenses make up a substantial part of operational costs, for businesses. As industries prioritize sustainability initiatives the integration of displacement pumps can support eco practices by reducing energy consumption.

Reduced Power Consumption

Variable displacement pumps offer an advantage in terms of minimizing power usage compared to displacement pumps that maintain steady speeds regardless of demand fluctuations. Variable displacement pumps adapt their output to match the requirements efficiently. This flexible approach results, in energy wastage. Contributes to substantial decreases in total power demands. Businesses do not enjoy cost savings. Also experience extended lifespan of their systems as a result of decreased strain, on electrical parts.

Optimized Flow Control

Variable displacement pumps offer a benefit in terms of optimized flow control well. You see the ability to tweak output enables these pumps to keep pressure levels steady, under operating situations. This adjustment feature helps reduce the chances of cavitation and other issues that might occur in pump setups lacking this adaptability. In the end, this optimized flow does not boost system efficiency. Also guarantees smooth processes without any disruptions.

Versatile Performance Across Applications

Variable displacement pumps demonstrate performance in a variety of settings. Highlight their adaptability well well-known in various industries, from automotive hydraulics to industrial machinery functions successfully meeting specific requirements, across different sectors is their forte ensuring that companies can tackle a wide range of fluid handling issues effectively as a result enterprises can enhance efficiency by incorporating variable displacement pumps into their processes.

Adaptability to Operational Demands

The ability of displacement pumps to adjust to changing needs is a major advantage, in industrial settings where things move quickly and adaptability is key for efficiency and effectiveness amidst varying conditions, in the system pressure and fluid properties requirements.

Suitability for Diverse Industries

Variable displacement pumps are used in industries, like oil and gas production or agriculture well as in manufacturing settings due to their efficiency and versatility that cater to the diverse needs of different sectors reliant on fluid control systems. With each industry posing its set of challenges the adaptability of displacement pumps enables businesses to enhance their operational flexibility. The consistent need for these pumps in use underscores their contribution, to contemporary industrial operations.

Maintenance and Durability Advantages

Variable displacement pumps offer benefits in terms of maintenance and durability that make them appealing for use, in operations. They run efficiently. Endures less damage than standard pumps, resulting in lower maintenance needs. This decrease, in upkeep does not save time and resources. Also boosts the overall lifespan of the equipment.

Lower Wear and Tear

Variable displacement pumps have the advantage of being able to adjust their output levels as needed over time which results in wear and tear on the machinery in the run compared to fixed output pumps that operate continuously at maximum capacity regardless of system demands This adaptability reduces strain, on internal parts and is especially advantageous in settings where pumps are used extensively and need to perform consistently Organizations see cost savings not only from reduced maintenance but also from improved dependability, in their hydraulic systems.

Extended Lifespan of Equipment

Variable displacement pumps are known for their durability. Can last longer, than pumping systems due to reduced wear and tear on the components they utilize. This extended lifespan brings about cost savings for businesses over time by reducing the need for replacements and allowing for longer periods of operational use of the pumps. Having equipment that lasts longer is especially beneficial in industries where downtime and replacement expenses can have an impact, on both productivity and profitability.

Case Application: POOCCA’s Variable Displacement Pumps

Features of POOCCA’s Variable Displacement Pump Models

POOCCA’s variable displacement pump models showcase advanced engineering designed to meet the demanding needs of various industries. They feature an innovative hydraulic control system that optimizes performance and ensures efficient fluid management. Additionally, POOCCA pumps are built with durable materials to withstand harsh operating conditions, providing reliability over extended periods. The integration of intelligent controls within these models enhances their ability to adapt to changing operational requirements seamlessly.

Industry-specific Applications and Success Stories

POOCCA variable displacement pumps have been successfully implemented in various industry-specific applications, showcasing their versatility and efficiency. In the construction sector, for instance, these pumps have improved the hydraulic systems of heavy machinery, leading to more efficient operations and reduced fuel consumption. Similarly, in the agricultural industry, farmers have reported enhanced irrigation control, resulting in better crop yields and reduced water waste. These success stories highlight the practical benefits that POOCCA’s variable displacement pumps bring to real-world applications.

Future Trends in Variable Displacement Pump Technology

Innovations and Technological Advancements

The upcoming developments, in displacement pump technology are set to make strides thanks to advancements in materials engineering and design innovation driving the field forward. The integration of technology and IoT capabilities will empower these pumps to deliver real-time information to operators, for control and efficiency gains. Furthermore, new material science breakthroughs will result in sturdier pumps that are easier to install and maintain while extending their longevity.

Environmental and Economic Impacts

As companies worldwide place importance, on sustainability efforts in their operations and practice the significance of displacement pumps in cutting down energy usage and environmental harm cannot be underestimated. These pumps are expected to see increased use as businesses aim to enhance efficiency and lessen their impact. Therefore, variable displacement pumps not only bring advantages by reducing expenses but also play a role, in promoting environmental well-being and supporting overall sustainability objectives.