Understanding Hydraulic Double Gear Pumps: Basics and Applications

What Is a Double Gear Hydraulic Pump?

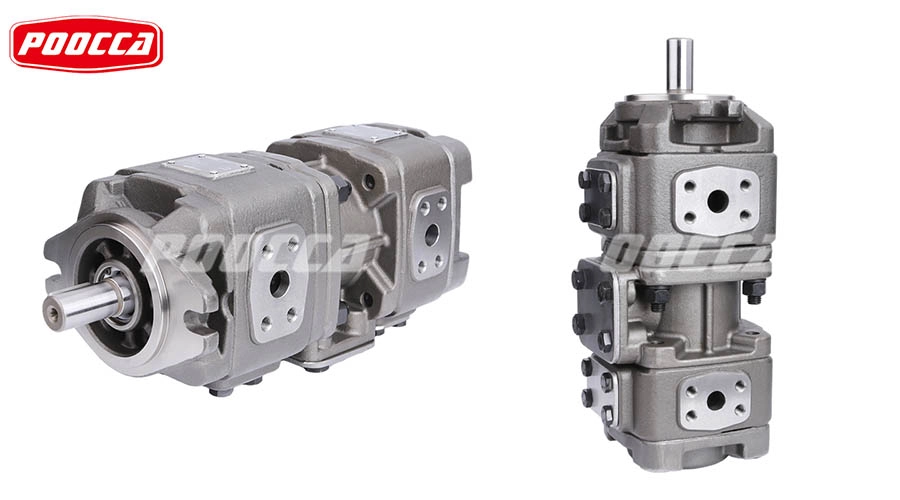

A double gear hydraulic pump is a variety of positive displacement pump. It employs two pairs of gears to move hydraulic fluid and create pressure. Unlike single-stage gear pumps, a double stage hydraulic gear pump offers two phases of fluid movement. This design enables greater effectiveness and better pressure management. These pumps are frequently utilized in hydraulic setups. They are vital where steady power delivery and toughness are critical.

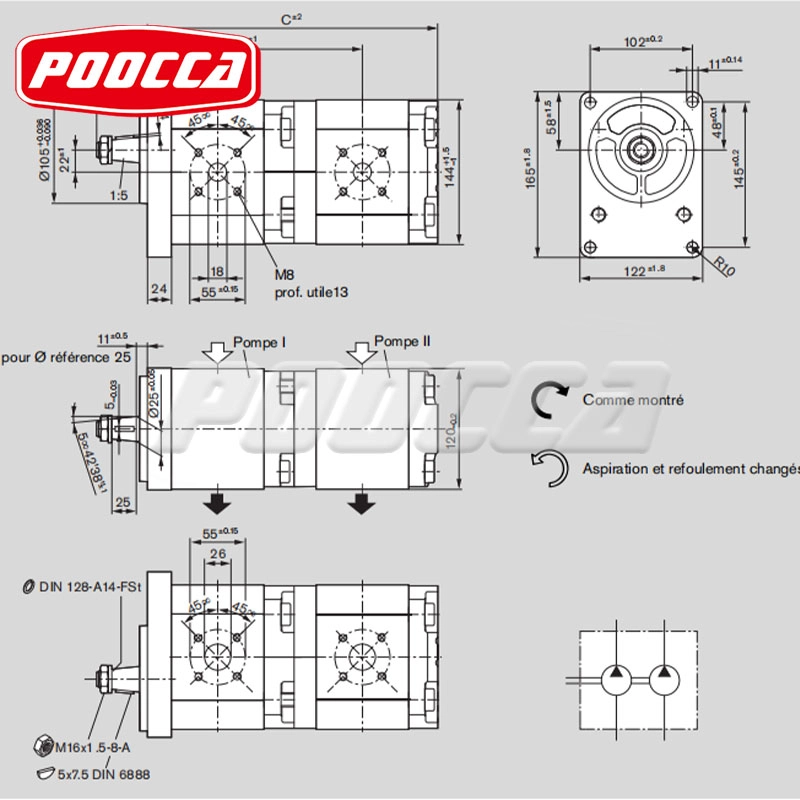

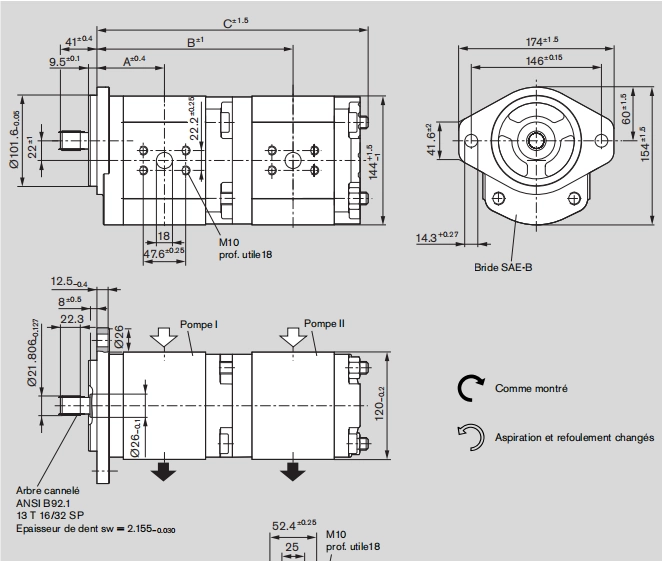

The main parts of a double gear hydraulic pump consist of a casing, driving and driven gears, shafts, and pressure outlets. The accuracy of these elements shapes the pump’s performance and durability. Sectors like building, farming, and goods handling depend on these pumps. They value their strong operation in demanding equipment.

Common Applications of Hydraulic Double Gear Pumps

Hydraulic double gear pumps are broadly applied in machines needing reliable fluid pressure and smooth power transfer. In the building sector, they often appear in diggers, loaders, and cranes. They guarantee fluid hydraulic motion. Farm equipment such as tractors and reapers also relies on these pumps. They sustain ideal hydraulic force for lifting and steering.

Mining activities use double gear hydraulic pumps in drill rigs and transport systems. Here, strong torque and ongoing function are vital. Moreover, factory automation setups and hydraulic presses gain from the dual-stage feature of these pumps. It provides exact control over fluid energy uses.

Advantages of Double Gear Hydraulic Pumps

One major perk of hydraulic double gear pumps is their productivity. They supply a constant fluid stream, cutting down on pressure swings. This ensures dependable machinery function. Sturdiness is another plus. These pumps are built to endure intense pressure settings and harsh work environments.

When compared to other hydraulic pumps, like vane or piston types, double stage hydraulic gear pumps often prove more budget-friendly. They offer solid results with a smaller upfront cost. This makes them perfect for cost-aware fields without losing productivity. Their straightforward build also simplifies upkeep and fixes.

Key Factors to Consider When Selecting a Hydraulic Double Gear Pump

Pressure and Flow Rate Requirements

When picking a hydraulic double gear pump, matching its pressure and flow rate to the equipment’s needs is crucial. You should calculate the system’s necessary PSI (pounds per square inch) and GPM (gallons per minute). This ensures the pump provides enough strength without excess stress.

Choosing a pump with suitable pressure ability avoids problems like overuse of energy or equipment breakdowns. A pump too feeble for the setup might falter in keeping proper hydraulic action. However, an overly large pump could cause wastefulness and higher running expenses.

Material Compatibility and Environmental Conditions

The substances in a double gear hydraulic pump affect its lifespan and resistance to damage. Top-grade cast iron or stainless steel parts are advised for settings with heavy pressure needs or contact with harsh liquids.

Temperature impacts pump operation too. In chilly weather, hydraulic fluids may thicken, lowering productivity. On the other hand, extreme heat might break down fluids and speed up wear on pump pieces. Selecting a pump with materials fit for particular work conditions boosts lasting dependability.

Size, Weight, and Space Constraints

Equipment design greatly influences pump choice. Double stage hydraulic gear pumps deliver improved output. Yet, they might demand more room for fitting than single-stage versions. Balancing power with space limits is key. The pump must suit the current system layout.

Light yet powerful models suit mobile hydraulic setups, like farm or building vehicles. Small designs preserve productivity without adding extra bulk to machines.

Energy Efficiency and Long-Term Costs

Cutting running expenses matters to most fields. An energy-saving hydraulic double gear pump reduces fluid leaks and inner friction. This leads to less power use. Pumps with finely crafted gears and streamlined flow paths cut energy loss. They enhance overall system productivity.

Thinking about upkeep and repair expenses is also vital. Spending on a top-notch pump with a lengthy life can avoid frequent swaps and idle time. Reviewing maker warranties and support options keeps upkeep costs reasonable.

Step-by-Step Guide to Evaluating Hydraulic Double Gear Pump Options

Step 1: Define Your Machinery’s Operational Needs

Grasping your hydraulic system’s exact demands is the starting point for choosing the right pump. Evaluate aspects like working pressure, needed flow rate, and work cycle. Surroundings factors, such as heat and exposure to dirt, also affect pump toughness.

Step 2: Compare Pump Specifications

Studying technical details aids in finding the top pump for the task. Crucial points include displacement size, top RPM, and productivity scores. Some pumps provide adjustable displacement options. These allow more adaptability across various work states.

Step 3: Assess Brand Reputation and Support

Opting for a pump from a trusted maker ensures dependability and output. Firms with ISO or CE credentials offer confidence in quality and field standards. Plus, after-sale help, like warranties and client service, matters in buying decisions.

Step 4: Test for Compatibility and Performance

Before locking in a purchase, running output tests or simulations confirms the pump meets work needs. Trying the pump in real work settings ensures proper action. It also prevents pricey mismatch problems.

Innovations in Double Stage Hydraulic Gear Pump Technology

Smart Hydraulic Systems and IoT Integration

Progress in hydraulic tech has brought smart tracking systems. IoT-ready pumps can give live data on metrics like pressure, heat, and wear rates. This aids in predicting upkeep needs and avoiding sudden breakdowns.

Eco-Friendly Designs for Sustainable Operations

Today’s double gear hydraulic pumps include green features. These cover noise-lowering tech and power-saving builds. Using eco-safe hydraulic fluids and reusable materials also cuts the ecological footprint of hydraulic setups.

Customization Trends in Hydraulic Pump Solutions

Many fields need custom hydraulic answers for unique work demands. Adjustable pump designs allow tweaks in gear size, material picks, and pressure levels. Makers like POOCCA hydraulic double gear pump provide tailored options. These boost productivity and output in niche uses.

Maintenance Tips to Extend the Lifespan of Your Hydraulic Pump

Routine Inspection and Fluid Management

Regular care is essential to stop failures. Checking hydraulic fluid state, watching for leaks, and reviewing gear setup can lengthen the pump’s life. Dirty fluid may lead to early wear. Thus, using top-grade hydraulic oil is key.

Addressing Common Wear-and-Tear Issues

Typical troubles like seal wear, gear mismatch, and overheating can hit pump output. Spotting these early and swapping out worn bits quickly keeps productivity intact.

When to Repair vs. Replace Your Pump

Weighing repair costs against replacement matters for lasting system wellness. If fixing costs top a big chunk of a new pump’s price, swapping the unit might be wiser. Tracking output over time shows when a pump nears its end.

FAQs About Choosing Hydraulic Double Gear Pumps

How do I pick the right hydraulic pump for my equipment?

Choosing a pump based on pressure needs, flow rate, and toughness ensures peak output.

What are the main differences between gear pumps and piston pumps?

Gear pumps are simpler and more wallet-friendly. Piston pumps, though, offer greater pressure strength.

How do you size a hydraulic double gear pump?

Correct sizing means figuring the system’s needed flow rate in GPM and pressure in PSI.

Can a double stage hydraulic gear pump manage thick fluids?

Yes, it can. However, using proper materials, like toughened gears, is crucial for thick fluids.

Final Thoughts: Optimizing Your Machinery’s Performance

Picking the ideal hydraulic double gear pump ensures productivity, toughness, and cost cuts. Reviewing specs, factoring in surroundings, and keeping up regular checks extend the pump’s life.

For fields needing custom answers, POOCCA’s hydraulic double gear pump services offer bespoke designs, factory rates, and worldwide shipping. Reach out today to find the top hydraulic pump for your needs.