Generally speaking, external gear pumps are one of the most popular positive displacement pumps due to their simplicity, reliability, and economic design. Being applied in an industry, they create a fluent and smooth process of fluid transfer. Now, let’s get some knowledge about the advantages of external gear pumps, their working principle, and why they are the necessary choice for many industries.

How External Gear Pumps Work: The Basics

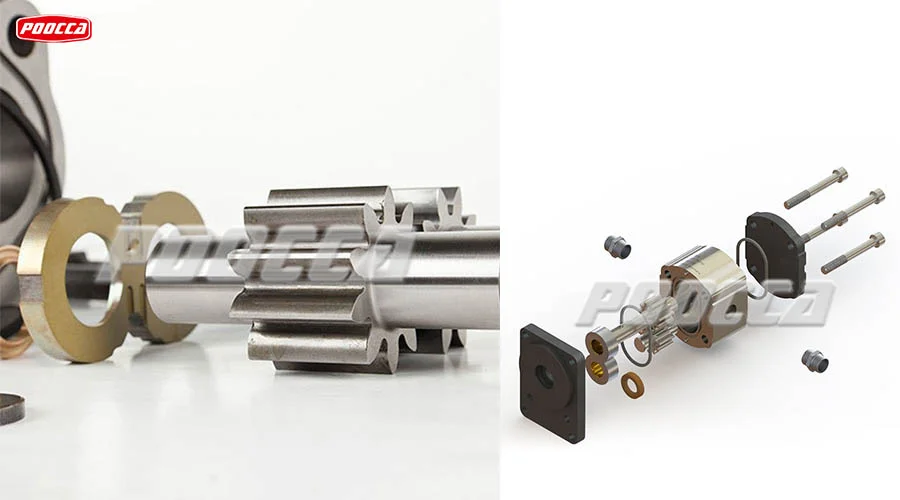

The working of an external gear pump has to be explained in order to understand the advantages. An external gear pump contains two interlocking gears inside the pump casing-one driving and the other driven. During operation, these gears tend to create a void during the suction part of the working cycle, sucking the fluid into the pump. As they continue to rotate, this fluid is replaced and pushed out through the discharge port, allowing a continuous flow.

This simplicity of mechanism, besides a few components, is some of the reasons why external gear pumps can achieve high efficiency. Such a design further ensures these pumps can handle multiple fluid types, including oils, lubricants, and other low-viscosity liquids.

Advantages of External Gear Pumps: Why Use Them?

With so many advantages of using external gear pumps, it justifies the reason they can be put to a wide variety of industrial and commercial uses. Some of the key advantages of an external gear pump include the following:

Compact and Simple Structure

One of the prime advantages of an external gear pump is that it is compact. The structure is simple and contains fewer moving parts, hence less operational and maintenance hassle.

High Efficiency in Fluid Transfer

The simplicity of the design in an external gear pump allows high efficiency in the transfer of fluids. A gear pump works very well in applications that involve the smooth and continuous flow of fluids, especially for liquids operating under medium to low pressures.

Cost-Effectiveness

New gear pumps also range moderately in price among other pump kinds, such as piston or screw pumps. These have a pretty simple construction with less initial investment; lesser the maintenance further on.

Reliability and toughness

The external gear pumps have also proved very reliable for operation on a continuous basis. Their sturdy construction ensures that they are resilient to the whims of the operational environment and hence can be applied even in those areas that are considered industrially demanding.

External Gear Pumps-Performance: Efficiency and Reliability

The factor of performance is important when choosing any pump. The performance of external gear pumps is incomparable, since the fluids to be transferred can range from lubricants and oils to chemicals. Due to their simple and effective design, these pumps assure reliability and consistency in their operation even under extreme conditions. Besides, the high efficiency of external gear pumps promotes energy saving and reduced operation costs.

Besides, the efficiency of an external gear pump during heavy-duty performance is quite amazing; this enables such pumps to provide the amount of flow that is required while consuming as little energy as possible. Low-noise external gear pump variants are applications where noise should be reduced. Hence, application in an atmosphere where noise emission is a challenge is recommended for them.

Application of External Gear Pumps: Versatile and Reliable Solutions

The flexibility with which external gear pumps are designed has widely spread their usage over a variety of industries, starting from the transfer of oil and fluids, lubrication systems, fuel oil handling, to even chemical processing. They work exceptionally well in power steering and hydraulic systems that need consistent flow or have reliable flow.

The viscosity control external gear pump will be helpful in those industries where providing highly accurate regulation of the flow of viscous liquids is necessary. Such pumps ensure that the obtained viscosity corresponds to the required condition and hence will add to the general effectiveness of the whole system.

Besides industrial use, high flow rate external gear pumps find their application in automotive and manufacturing and mining applications for cost-effective solutions to fluid management.

External Gear Pump Maintenance: How to Maintain the Equipment under Optimal Conditions

The best way to ensure that an external gear pump performs for a long period is by regular maintenance. These pumps, being of a relatively simple construction, are easier to maintain compared to more complex pump designs. Routine checks on gears, seals, and fluid quality will prevent their premature wear and damage.

In addition, the best industrial external gear pump involves the selection of models designed to be long-lasting. For example, POOCCA external gear pumps are designed for high efficiency and longevity, even in the most adverse working conditions, requiring less maintenance.

Why Choose POOCCA External Gear Pumps?

POOCCA Hydraulic Co., Ltd, Shenzhen, is one of the leading hydraulic equipment manufacturers that offer a wide range of high-quality external gear pumps in several series. Since 2006, POOCCA has earned a good reputation in this field by supplying products to worldwide partners with competitive factory prices. Series of POOCCA External Gear Pump: AZPF, AZPG, SGP, and PGP, highly effective, reliable, and economical.

That is why, in the case of POOCCA, one of the striking features for the external gear pumps is customized products according to customer needs. From an ideal pump which suits applications dealing with oil and fluid transfers, to a model that fits high-pressure deals, POOCCA has a solution for all in the way of acquiring an appropriate pump.

Pros and Cons of External Gear Pump: A Balanced View

While external gear pumps enjoy all the advantages of positive displacement pumps, limitations of the above said pumps must be looked into. First and foremost, in application and areas needing high-pressure higher tolerances and precision these pumps just cannot work aptly. These pumps also develop operational problems if the fluid contains solid particles which may lead to wear and breakdowns.

However, external gear pumps have the potential to provide unmatched efficiency and reliability in service with clean, non-abrasive fluids. Noise-free operation, compact size, and reasonable prices have made them suitable for many industries.

Conclusion: How External Gear Pumps Benefits an Industry

Conclusion, external gear pumps boast an enviable list of advantages that make them indispensable in many industrial applications. Their design is simple and thus reliable, with consistent fluid flow; cost-effective and durable, they present themselves as one of the best options for enterprises desiring to rationalize their process of fluid transfer.

From high flow rates to viscosity control and further to oil and fluid transfer, the externally gear-driven pumps shine out, especially the ones offered by POOCCA. The excellent performance, in addition to their reliability and low maintenance, means smooth operations with minimal downtime and lower operating costs.