In an attempt to choose the most ideal gear pump for a system, this has proved to be an uphill task. There are lots on sale that exhibit different properties. Hence, there exists a dire need to pinpoint their differences, thus giving room to choose one which will be most ideal in your system. A reliable high-pressure gear pump can significantly improve system performance, extend the life of your machinery, and reduce maintenance costs. In this guide, we’ll explore the different types of gear pumps available in the market and provide expert insights on how to choose the right one for your application.

Understanding the Critical Role of gear pumps in Hydraulic Systems

gear pumps play a great role in any industrial system wherever the availability of efficient lubrication or fluid transfer is concerned. These pumps ensure proper lubricating oil distribution inside the gearbox, which is very critical for proper functioning. From high-pressure lubrication systems to low-viscosity gear pumps, each has its own influence on efficiency and longevity. Their wide application can be seen in gear pumps in automotive industries, manufacturing industries, and hydraulic systems related to heavy machinery.

The selection of the correct, high-efficiency gear pump is very important. Where there is an inability to achieve the required flow rate or pressure, this will finally result in poor lubrication performance, overheating, excessive wear, and costly downtime. Power Transmission Engineering goes in-depth with technical issues of gear pump systems, presenting actionable insights that will drive businesses toward better decisions.

Types of gear pumps and Their Applications

In general, there are a few different configurations for gear pumps; each such configuration has very specific operational requirements. With differences in flow rate and pressure, and viscosity of the oil, one or another type will serve your purposes best. We shall cover the most common types of high-performance gear pumps used within industry.

External gear pumps

Among the very common types of gear pumps is the external gear pump, which consists of a pair of meshing gears transferring oil from the inlet to the outlet. In the case of externally geared pumps, they are usually preferred in those applications where gear oil needs to be circulated at moderate pressures. Large features for the externally geared pumps include their simpler construction and lower maintenance cost with the ability to run over a wide range of viscosity. They may not turn out to be a suitable choice for high-pressure lubrication applications or those requiring high levels of accuracy of flow control.

It is for these reasons that externally geared pumps find a very suitable application in the fields of gear lubrication in automobiles, hydraulic fluid transfer systems, and in the industrial manufacture of products requiring reliability combined with low maintenance.

Internal gear pumps

The only design difference between an internal and an external gear pump is that, in an internal gear pump, one gear is situated inside the other. With this design, the flow is smooth, with high suction capacity, particularly for high-viscosity gear oils. The application of an internal gear pump is done where flow rate control is required with the highest degree of accuracy. Such applications are related to oil field equipment, hydraulic press, and geared motor for which higher suction and consistency in flow are needed.

Thus, as they are capable of using thickened oils and continuing at the same flow in different pressures, internal gear pumps might prove to be very effective for heavy industrial systems.

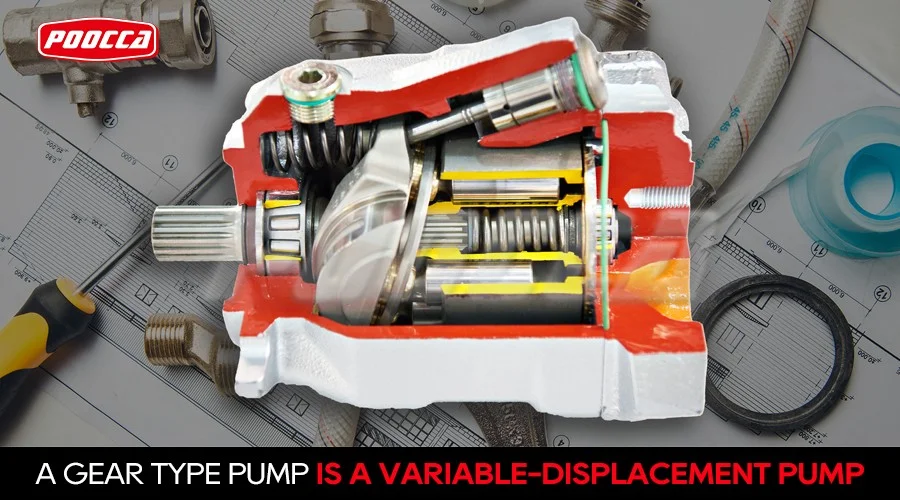

Piston gear pumps

A good selection for applications requiring high-pressure gear pumps is a piston gear pump. Basically, piston pumps work on the principle of the fluid being displaced by pistons. Hence, they can have really much higher pressure ratings compared with external or internal gear pumps. A few of their applications are heavy machinery lubrication systems and high-pressure hydraulic equipment where powerful, very accurate lubrication is required.

Piston gear pumps apply quite well to automotive machinery, hydraulic systems, and offshore oil rigs because the applications can rely on high-pressure gear oil.

How to Choose a gear pump for an Application

An industrial gear pump selected may take up to several variable forms which have to be accounted for before the pump serves for a purpose that will satisfy one’s systems based on operational requirements; for instance, viscosity, the gear flow, the operational pressure required in one cycle, and maintenance.

The type of pump used is critically dependent on the viscosity of the gear oil being pumped. Thicker oils require pumps that have high suction capability and capacity for generating high pressure. Internal and piston gear pumps are good on high-viscosity oils; external gear pumps are better suited to lighter oils and applications with moderate pressures.

Another important consideration is the cycle for maintenance of the pump itself. Pumps used either for continuous operation or in aggressive operating environments may require more frequent service cycles. Thus, the selection should have a robust gear pump for the operational environment presented for the purpose of minimizing maintenance frequency to reduce costs and minimize potential down times.

Importance of Choosing a Trustworthy gear pump Supplier

One thing with choosing a gear pump supplier is being sure that he is dealing with a company that can provide quality pumps aside from technical support and custom solutions to meet specific needs. A good supplier will, therefore, be able to give advice on the selection of the right pump for your application, whether it is a high-pressure gear pump, a self-priming internal gear pump, or a low-cost external gear pump.

POOCCA Hydraulic (Shenzhen) Co., Ltd. – The Trusted Gear Oil Pump Manufacturer

POOCCA Hydraulic Shenzhen Co., being in the forefront in supply with the high quality gear pump, is among such a business enterprise to which confidence could be bestowed. For more than 20 years, the corporation, POOCCA, has focused on designing and manufacturing with maintenance of various hydraulic products including gear pump. Its product line entails external gear, internal gear and piston gear pumps for high-pressure lubrication systems, heavy machinery, automotive, and general industrial applications.

POOCCA designs and develops gear pumps with unparalleled durable performance. This enterprise is in the frontline, leading hydraulics systems, machinery lubrication lines, and industrial manufacturing sectors. In addition to that, the company does special designs for application-specific requirements, making sure each pump performs with efficiency anywhere put to work.

POOCCA works in more than 100 countries around the world, building long-lasting relationships with customers from the U.S., Russia, Brazil, Thailand, among others. With gear pumps available at cost-friendly prices, customer satisfaction also becomes one of the major reasons behind their leading positions in this line of trade. Whether heavy-duty piston gear pump or low maintenance-cost external gear pump, POOCCA will be your professional advisor and supplier.

It also means the best lead times from factories and a 12-month warranty for its products-all in ensuring peace of mind for its clients. ISO 9001 quality certified, each product at POOCCA undergoes stringent quality testing for the purpose of making environmentally friendly solutions-sustainable use in hydraulic applications.

When searching for a reliable partner to provide your needs in gear pumps, POOCCA Hydraulic is going to be the one that would always lead. Equipped with loads of experience, it works on a very important principle-to satisfy its customers-which means that it is an ideal choice for business establishments requiring high-quality gear pumps meant for industrial systems.

For more information on gear pumps from POOCCA, or to request a quote, please visit: www.poocca.com or call +86 18988788332. Alternatively, please email your project’s requirements to sales@kamchau.com.