Understanding Vane Pumps

Overview of Vane Pump Technology

Vane pumps are a type of positive displacement pump that utilizes vanes mounted on a rotor to create a hydraulic seal against the pump casing. As the rotor spins, the vanes extend and retract, trapping fluid between them and the casing, thereby moving it from the inlet to the outlet. This technology is widely used in hydraulic systems due to its ability to handle varying pressures and flow rates with high efficiency.

Key Differences Between Single and Double Vane Pumps

The primary distinction between single and double-vane pumps lies in their configuration. A single vane pump features a single set of vanes within its rotor, while a double vane pump comprises two sets of vanes operating in tandem within a unified housing. This dual setup allows double-vane pumps to offer greater flow rates and pressure capabilities compared to their single-vane counterparts.

Single Vane Pump: Features and Benefits

Design and Configuration

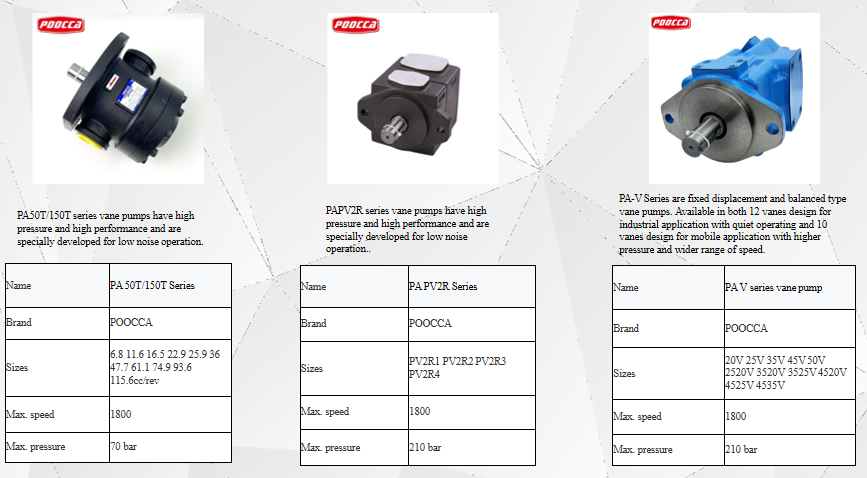

Single vane pumps are typically designed with either 10 or 12 vanes, depending on their intended application—industrial or mobile. This balanced design ensures smooth operation with minimal vibration, contributing to their reliability in various settings.

Efficiency and Performance

Single vane pumps are well regarded for their efficiency levels because of their fixed displacement design that ensures performance under varying operational circumstances. They come in a range of options to meet application requirements.

Noise Considerations

Single vane pumps have the benefit of operating due to their balanced design which effectively minimizes noise levels. This makes them a great choice for places where noise pollution is an issue.

Volumetric Efficiency

These pumps show performance in terms of volume efficiency. Can sustain a steady flow rate regardless of changes in pressure levels. This feature makes them perfect for tasks that demand accurate fluid management.

Typical Applications

Single vane pumps are flexible and suitable for uses across industries such as industrial machinery and mobile equipment or hydraulic systems that require both high pressure and adjustable flow rates.

Double Vane Pump: Features and Benefits

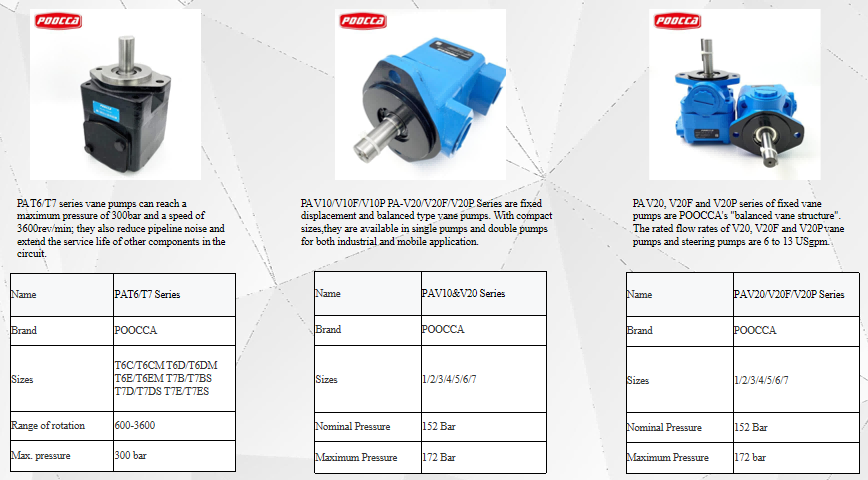

Dual-Blade Design

Double vane pumps have a two-blade setup that lets them perform two tasks at once in a compact unit boosting their efficiency by allowing the pump to deliver two flow streams simultaneously from one body.

Flow and Pressure Capabilities

The use of double-vane pumps in a tandem configuration enables increased flow rates and better handling of pressures compared to single-vane variants making them ideal for challenging tasks that demand performance, in high-pressure environments.

Pressure Handling

Vane pumps are designed to withstand pressure levels making them perfect for industrial use where reliability is crucial as they can handle demanding operations without sacrificing performance quality.

In summary, the decision to opt for either a single or double vane pump hinges, on the needs of the application – like the preferred flow rate, how much pressure it can handle, noise levels to consider, and space limitations. POOCCA provides both options to suit a range of requirements guaranteeing top-notch performance in hydraulic setups.

Factors to Consider When Choosing Between Single and Double Vane Pumps

Evaluating System Requirements

Flow Rate Needs

When deciding between a vane pump and a double vane pump for your system needs; it’s important to consider the flow rate requirements of the setup Single vane pumps are known for their flow rates thanks to their fixed displacement design. Suitable for applications that require fluid control. On the other hand; double-vane pumps can provide flow rates due to their tandem setup; making them perfect for systems that need significant fluid movement. Understanding the flow rate demands of your application will help you select the type of pump, for your needs.

Pressure Specifications

Pressure requirements play a role in the decision-making process when it comes to choosing the right pump type for your needs. Single vane pumps are known for their ability to handle pressures effectively and are ideal for applications that require pressure levels. On the other hand, double vane pumps are well suited for environments that require pressure capacities due to their dual blade design, which enables them to handle increased pressure without sacrificing performance. Evaluating the pressure requirements of your system is crucial in determining which pump configuration best meets your requirements.

Assessing Energy Efficiency

Mechanical vs. Volumetric Efficiency

Energy efficiency is crucial when choosing a pump as it affects its performance in ways. Mechanical efficiency looks at how a pump can convert the energy it receives into energy without losing too much along the way. On the other hand, Volumetric efficiency focuses on how a pump can deliver the right amount of fluid in various situations. Single vane pumps are known for their efficiency thanks to their balanced design and minimal moving parts, which helps cut down on energy usage. Meanwhile, double-vane pumps excel in volumetric efficiency because they can provide two output streams that help distribute fluid in systems.

Noise Level Preferences

Impact on Environment

Excessive noise can have an impact on the surroundings and the lifespan of machinery in use; Single vane pumps are well known for their performance making them a good fit for places that require low noise levels like hospitals or residential areas; thanks to their balanced rotor design that reduces vibrations and noise during operation. Double vane pumps also keep noise levels low but might produce a bit of sound due to their setup; it’s important to think about the environmental effects of noise when choosing a pump type.

Application-Specific Noise Constraints

In some situations or settings, like workplaces with heavy machinery operations noise reduction is essential to ensure a safe and pleasant work atmosphere where selecting a pump considering noise levels becomes significant for example choosing a single vane pump could be beneficial due, to its quieter operation features.

Maintenance and Cost Implications

Long-term Operational Costs

Consider the costs over the run when deciding between single and double vane pumps as part of your decision-making process in selecting one option over the other for your needs. Single vane pumps typically demand upkeep owing to their structure and fewer elements involved in their operation which can lead to reduced expenses in the long term. On the contrary double vane pumps might result in increased maintenance costs due, to their design and added components that might require attention and care as time passes.

Ease of Maintenance

Maintenance convenience is a factor to think about well. Single vane pumps are usually simpler to upkeep since they come with components in motion and straightforward assembly steps. This simplicity leads to time spent offline during repairs or regular upkeep activities. On the other hand, double vane pumps may need intricate maintenance due, to their tandem setup but they provide added features that might make the extra work worthwhile.

Enhancing System Performance with POOCCA Solutions

POOCCA provides an array of solutions that aim to improve system performance, in different industries effectively and reliably by offering single and double-vane pump choices tailored to various application needs.

When it comes to tasks requiring control, overflow, and quiet functioning requirements in mind POOCCAs single vane pumps excel in providing performance while keeping noise levels to a minimum Their sturdy construction guarantees reliable output even when dealing with varying pressure circumstances which makes them perfect, for delicate settings

POOCCAs double vane pumps provide flow rates and pressure capacity ideal, for demanding environments. They are designed with blades to efficiently handle two functions in tight spaces—a great fit for machinery that needs adaptable fluid distribution solutions.

In summary, deciding between double vane pumps requires an evaluation of system needs like flow rate requirements, pressure specifications, energy efficiency preferences, noise level limits, maintenance considerations, and cost elements. POOCCA’s wide range of products offers customized solutions that effectively meet these standards— guaranteeing operation for hydraulic systems while upholding top-notch quality and dependability.