In the world of hydraulic systems, the choice between axial and radial piston pumps can significantly impact performance and efficiency. Understanding the distinctions between these two types of pumps is crucial for engineers and professionals seeking optimal solutions for their applications. This article examines the fundamental characteristics, key differences and specific advantages of axial piston pumps while also considering potential drawbacks.

What are Axial and Radial Piston Pumps?

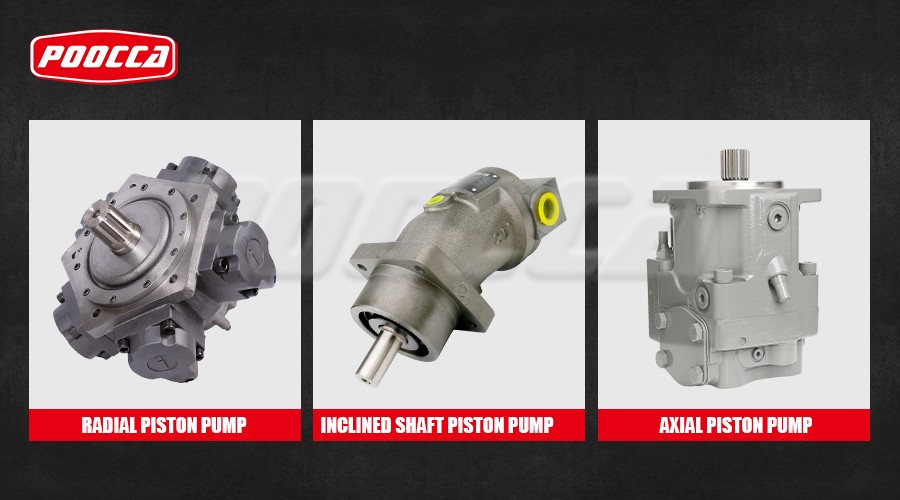

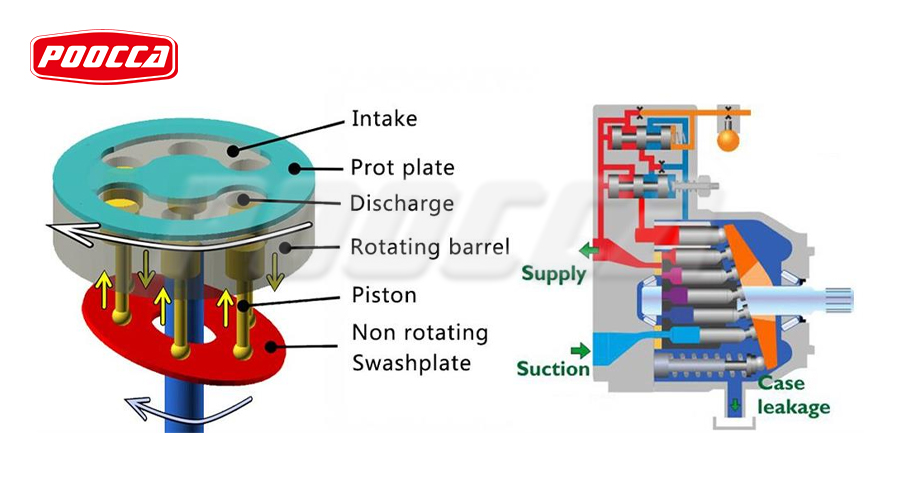

Axial and radial piston pumps are types of hydraulic pumps that convert mechanical energy into hydraulic energy. An axial piston pump consists of a series of pistons arranged parallel to the drive shaft, allowing for efficient fluid movement through the system. This configuration typically offers a more compact design and can handle higher pressures compared to its radial counterpart. Conversely, radial piston pumps feature pistons arranged perpendicular to the drive shaft, rotating around a central axis. This layout can provide a more uniform flow characteristic and is often used in applications requiring lower operational noise levels.

Fundamental Characteristics

Axial piston pumps are widely recognized for their efficiency and ability to function effectively under operational circumstances. These pumps are especially useful in setups requiring displacement and high-pressure levels. Their design facilitates integration with control systems which adds to their versatility for various hydraulic configurations. In contrast, radial piston pumps shine in scenarios with requirements and emphasize the importance of minimizing pulsation and noise. They typically strike a balance between performance and maintenance due to their mechanical parts.

Key Differences

The design and operational features of axial and radial piston pumps show variations worth noting. Axial piston pumps are known for their construction that enables efficiency and pressure capabilities. When it comes to flow rates axial piston pumps excel in handling volumes because of how their pistons are arranged. On the other hand, radial piston pumps offer advantages, like maintenance and lower service costs despite their less complex design. The choices among these designs frequently determine their appropriateness for sectors and uses; comprehending these distinctions is crucial for making informed decisions.

Why Consider Axial Piston Pumps?

Opting for a piston pump in systems offers numerous benefits that can improve system efficiency significantly. These pumps excel in handling pressures and delivering increased flow rates which make them ideal for demanding tasks in sectors like construction and manufacturing industries. Moreover, their capacity for adjusting displacements enables control over system outputs leading to effectiveness. The durable structure and established dependability of piston pumps further extend longevity cutting down expenses related to downtime and upkeep.

Specific Advantages of Axial Piston Pumps

Axial piston pumps have a benefit, in how they convert input power into hydraulic power by minimizing energy loss. A crucial aspect in applications sensitive to energy usage. They are also versatile when it comes to handling load conditions and can sustain performance in changing environments. This flexibility makes axial piston pumps ideal for a range of uses. From machinery to industrial operations that require both adaptability and reliability.

Potential Drawbacks to Keep in Mind

Although axial piston pumps offer benefits they do come with some downsides that need to be taken into account. The intricate design of these pumps can result in production expenses and more maintenance difficulties. Moreover, their susceptibility, to contaminants may create hazards requiring the implementation of top-notch filtration systems to safeguard the pump parts. While axial piston pumps excel in high-pressure scenarios users needing pressure outputs may prefer radial piston pumps for their cost-effectiveness.

To explore the world of hydraulic solutions further, I invite you to discover POOCCA, a company that specializes in high-quality hydraulic components, including both axial piston pumps and radial piston pumps. POOCCA offers a diverse range of products and services designed to meet the dynamic needs of various industries, ensuring performance and reliability across the board. For more information on our offerings and how we can support your hydraulic needs, please visit POOCCA.

Why Opt for Radial Piston Pumps?

Radial piston pumps are highly valued in settings because of their distinctive structure and performance features. They achieve a flow rate by positioning the pistons at angles, to the drive shaft. A crucial advantage in applications that require reliable performance. Their compact design is also advantageous in systems with space. Additionally, Radial piston pumps are known for their vibration and noise levels making them a preferred option for environments with noise disturbances.

Chief Benefits of Radial Piston Pumps

Radial piston pumps offer the benefit of being highly dependable and requiring maintenance tasks to keep them running over time. Their structure helps minimize wear and tear within the pump parts by reducing strain. Resulting in longer periods between servicing and a prolonged lifespan. Compared to more intricate piston pumps in design; radial piston pumps are easier to repair when maintenance is needed. This reliability factor can lead to cost savings in the run by reducing downtime and keeping maintenance costs in check.

Limitations to Consider

On the side of the coin, piston pumps do have their drawbacks. Even though they work great in situations they might not measure up in terms of pressure when compared to piston pumps. As a result, they might not be fit, for high-pressure systems that require top-notch performance. Moreover, the flow rates achievable with piston pumps may not be as impressive, as those of options which could limit their usability to specific scenarios with less demanding performance needs. It’s crucial to assess your application requirements before opting for these pumps.

Choosing the Right Pump for Your Application

Choosing the pump heavily influenced by the particular use case in question. Several elements like needs, fluid characteristics, system configuration, and financial limitations play a role in determining which pump is best suited for the job. Having a grasp of these factors is crucial for engineers and operators to enhance the efficiency and dependability of their systems.

Comparing Based on Application Needs

Industrial Hydraulics

In settings where machinery deals with changing loads and pressures axial piston pumps are commonly seen to excel. Their ability to handle pressures while offering flow rates provides flexibility to meet varying operational requirements. On the other hand, radial piston pumps may outshine industries where maintaining flow rates and minimizing maintenance is crucial particularly, in fixed installations.

Mobile Hydraulics

In industries like construction and agriculture where mobile hydraulic systems are used extensively for their durability and efficiency needs, axial piston pumps stand out as a choice due to their ability to handle pressure and adapt well to different load demands. Meanwhile, radial piston pumps, known for their operation and solid performance in certain conditions could also prove advantageous in mobile applications where reducing noise is a key concern.

Aerospace Applications

In the field of aerospace engineering the decision, between radial piston pumps is frequently influenced by performance criteria and safety regulations. The dependable nature and exceptional efficiency of piston pumps often lead them to be favored in aerospace settings that necessitate high pressures and precise regulation. On the other hand, radial piston pumps can be a selection in scenarios where reducing operational noise is important while ensuring consistent performance.

Cost vs Performance Ratio

When choosing pumps, for a specific use case scenario, it’s crucial to weigh the balance between cost and performance factors. Although axial piston pumps may come with a price tag initially because of their construction design their outstanding performance could result in reduced overall operational expenses in the long run. On the other hand, radial piston pumps may be more budget-friendly in terms of purchase costs. They may not meet the performance standards required for challenging applications. To make an informed decision it is advisable to evaluate both the initial investment and the ongoing operational expenses.

Longevity and Durability Factors

The lifespan and strength affect how sustainable hydraulic systems are in the run. Axial piston pumps can deliver top-notch performance. Might need care due to their sensitivity to impurities. Regular maintenance is key to preventing problems and extending their lifespan. On the other hand, radial piston pumps have a structure and usually need less maintenance making them known for their durability in different uses.

Additional Resources and Expert Guidance

When considering systems decisions, it’s vital to consult experts and explore resources for a better grasp of your application’s specific requirements. Various manufacturers offer guides and assistance to assist in selecting piston or radial piston pumps. Moreover collaborating with an informed vendor can offer insights into the technologies and products, on the market ensuring that your system is fine-tuned for top-notch performance and dependability.

Overall, the distinction between axial and radial piston pumps is fundamental in selecting the correct pump for your hydraulic system. By considering each type’s unique characteristics, benefits, and limitations, professionals can make informed decisions that enhance system efficiency and reliability.