Piston pumps play a role, in industries converting mechanical energy into hydraulic power by pushing fluid through hydraulic systems. By using the back and forth motion of pistons they create pressure and fluid movement within the pump setup. These pumps are crucial for a range of applications across industries like manufacturing, construction and automotive sectors. Knowing the distinctions, between axial piston pumps can significantly improve the effectiveness and dependability of systems.

Understanding Piston Pumps

Definition and Application of Piston Pumps

Piston pumps are devices that use power and pistons to move liquid. When the piston goes back and forth in a cylinder it pulls fluid in, on one stroke. Pushes it out on the next. This technology is used in industries, like machinery, hydraulic systems and farming equipment. One key advantage of piston pumps is their capability to manage pressures while keeping a flow rate.

Basic Working Principle of Piston Pumps

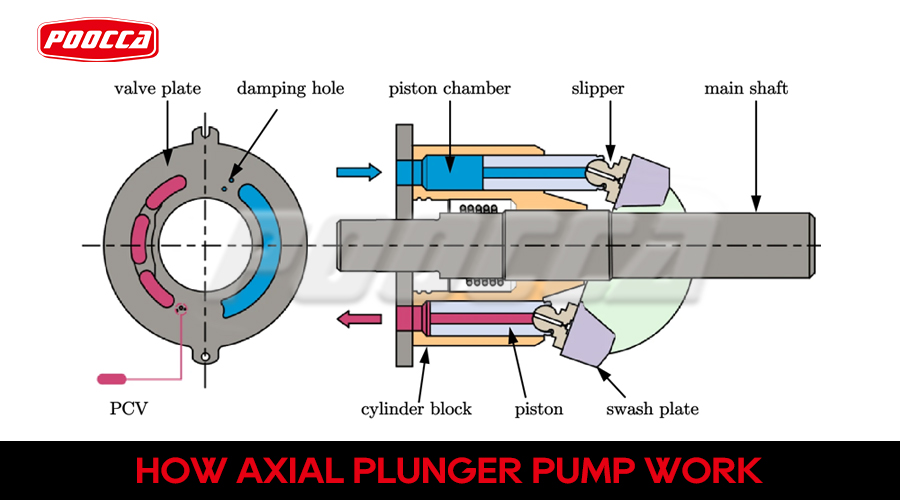

The fundamental concept, behind piston pumps is quite simple. In a chamber there is a piston that is connected to a crankshaft or a similar mechanism. When the crankshaft turns it causes the piston to move back and forth in a line inside the chamber. During the phase the piston moves backward creating a vacuum that enables fluid to enter through one or more valves. As the piston moves forward in the discharge phase the fluid is pushed out through outlet valves resulting in pressure build up, within the system. This repetitive cycle facilitates the flow of fluid allowing for the hydraulic work to be carried out effectively.

Importance in Different Industries

Piston pumps are highly important, across sectors because of their dependability and effectiveness. In construction they assist in pumping and material transfer. The automotive industry relies on piston pumps for steering and braking systems. Moreover these pumps see use in oil, gas, agriculture and manufacturing industries where precise fluid control’s essential. Therefore knowing about piston pump types like radial and axial is key to enhancing performance, for uses.

Key Differences Between Radial and Axial Piston Pumps

Structural Differences

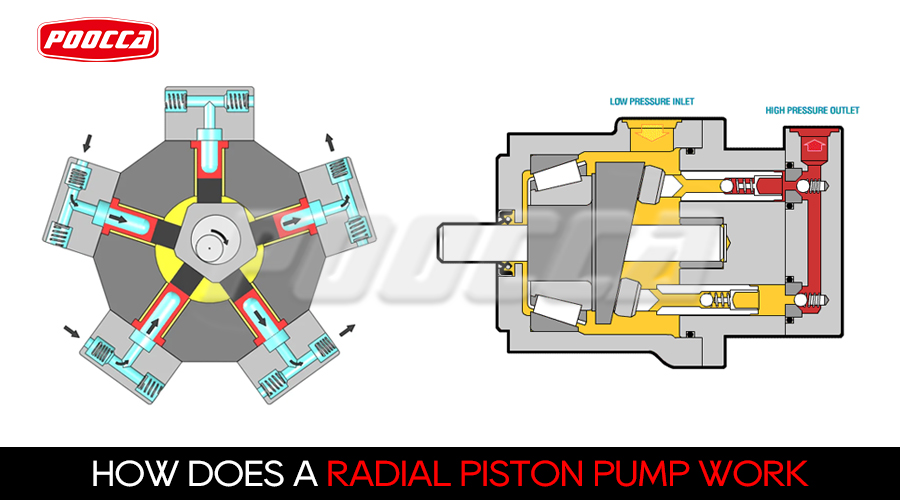

Radial and axial piston pumps have differences mainly in how they’re structured. Radial piston pumps have pistons positioned in a manner around a shaft with each piston functioning within its own cylinder. The movement of the drive shaft enables the pistons to move back and forth pulling in fluid and pushing it out. On the hand axial piston pumps have pistons aligned in a line, along the drive shafts axis. This design allows for an use of space and a compact structure as the pistons move parallel, to the rotation of the driving shaft.

Functional Performance Comparison

Efficiency and Operational Metrics

When it comes to how they work axial piston pumps are known for their effectiveness, in moving fluids especially when dealing with pressures and flow rates. These pumps can change the amount of fluid they pump based on whats needed which helps save energy. On the hand radial piston pumps can create pressure but may not be as efficient because of how they are built. Despite this radial pumps are a choice for tasks that require pressure more, than a consistent flow rate.

Maintenance Requirements

Maintenance requirements can also vary between the two types of piston pumps. Radial piston pumps tend to have more complex designs, which can complicate maintenance and increase the frequency of repairs needed. In contrast, axial piston pumps often have simpler configurations that allow for easier accessibility and maintenance. Regular inspection and upkeep of both types are essential for ensuring long-term performance and reliability.

Advantages and Disadvantages of Radial Piston Pumps

Pros of Radial Piston Pumps

High Pressure Capabilities

One of the primary advantages of radial piston pumps is their ability to generate high pressures. This makes them ideal for applications that require robust hydraulic power, such as heavy machinery and construction equipment. The design allows for a stable output even under high-pressure conditions, providing a consistent performance level.

Compact Design

Another benefit of radial piston pumps is their compact design. This enables easier integration into existing systems where space is a premium. The small footprint allows them to be deployed in tight locations without significantly compromising their operation, which is particularly valuable in urban construction and limited-access environments.

Cons of Radial Piston Pumps

Limited Flow Rate

Despite their strengths, radial piston pumps have some limitations, one of which is their relatively low flow rate compared to axial pumps. The design means that while they can handle pressure effectively, they may not be able to transfer fluid as quickly as axial types. This could be a disadvantage in applications that require rapid fluid movement.

Higher Initial Cost

Radial piston pumps often come with a higher initial investment due to their complex design and manufacturing processes. The increased cost can be a pertinent factor for businesses operating under budget constraints. Organizations must weigh the long-term benefits of high pressure and compact design against the upfront expenditure when deciding if a radial piston pump is the right choice for their needs.

In conclusion, radial and axial piston pumps each have their unique characteristics and applications. By understanding their differences, advantages, and disadvantages, businesses can make informed decisions regarding which type of piston pump is best suited for their specific hydraulic needs.

Advantages and Disadvantages of Axial Piston Pumps

Pros of Axial Piston Pumps

Axial piston pumps are characterized by several notable advantages that make them a preferred choice in many hydraulic applications. One significant benefit is their higher flow rate efficiency, which allows these pumps to deliver large volumes of fluid effectively. Their design enables them to achieve optimum flow characteristics, particularly in systems where variable flow requirements are essential. This efficiency translates to better energy utilization, making axial piston pumps suitable for both high and low-pressure applications.

Ease of maintenance is another advantage that users often appreciate. The straightforward construction of axial piston pumps typically means that they can be serviced with relative ease. Components can often be accessed without extensive disassembly, allowing for quicker repairs and reduced downtime. Moreover, regular maintenance tasks can be performed efficiently, contributing to prolonged service life and reducing operational costs over the long term.

Cons of Axial Piston Pumps

Despite their advantages, axial piston pumps are not without their disadvantages. One notable con is their larger footprint when compared to radial piston pumps. Their structural design demands more space for installation, which may not always be available in smaller or constrained environments. Consequently, when integrating these pumps into existing systems, users need to carefully assess available space to ensure compatibility.

Additionally, axial piston pumps may be susceptible to wear over time, particularly under conditions of high pressure or excessive operational cycles. The linear movement of the pistons creates friction, which can contribute to wear of internal components. This susceptibility necessitates regular monitoring and maintenance to avoid performance degradation. Users must be vigilant in maintaining the operational environment to mitigate these effects and ensure the longevity of axial piston pumps.

Choosing the Right Pump for Your Needs

Assessing Operational Requirements

Choosing the appropriate piston pump demands a detailed assessment of specific operational requirements. Factors such as fluid type, desired flow rate, and pressure levels must be analyzed before making a decision. For instance, the intended application might require a pump capable of handling high pressures, prompting the consideration of a radial piston pump. Conversely, if a higher flow rate is a priority, an axial piston pump might be more suitable.

Moreover, understanding the operational environment is crucial. Applications in extreme temperature conditions or locations with limited access can affect pump performance and maintenance requirements. Evaluating these operational factors allows users to make informed decisions about which type of pump will provide the desired performance while aligning with system constraints.

Evaluating Long-term Costs

Beyond just the initial purchase price, evaluating long-term costs is essential in the decision-making process for selecting a piston pump. These costs can include maintenance, energy consumption, and potential downtime. While radial piston pumps may carry a higher initial expense, their capability to handle high pressure consistently might yield lower repair costs over time in heavy-duty operations.

Alternatively axial piston pumps could require maintenance resulting in decreased long term operating expenses. As a result companies should evaluate these extended cost considerations in comparison, to the investment taking into account factors, like projected pump lifespan, maintenance schedules and overall operational effectiveness.

Introducing Poocca: A Reliable Source for Quality Piston Pumps

Overview of Poocca’s Product Line

Poocca is widely recognized as a provider of top notch piston pumps renowned for dedication to advancing technology and delivering exceptional performance. Our selection includes a variety of radial and axial piston pumps tailored to meet requirements. Every item is meticulously crafted for longevity, dependability and maximum effectiveness establishing Poocca as an option, for companies, in search of hydraulic solutions.

Poocca doesn’t just stick to designs; we also provide custom options, for needs. Customers can get solutions to tackle operational issues, which can improve productivity. With our support and maintenance services Poocca has solidified its reputation as a choice, for industry experts.

Special Features and Benefits Offered by Poocca

Pooccas piston pumps come with features that enhance their performance. Some models include cutting edge technology to reduce wear and enhance energy efficiency. The emphasis, on longevity results, in service intervals ultimately lowering expenses associated with maintenance and replacements.

In addition Poocca is dedicated to offering top notch customer assistance guaranteeing that customers get advice every step of the way when choosing and maintaining their pumps. Our materials, such, as product guides and instruction manuals enable users to optimize their pump performance. Poocca stands out as a premier provider of top tier piston pumps in the industry thanks, to its advanced engineering, customized solutions and attentive customer support.

To sum it up it’s crucial to grasp the pros and cons of radial and axial piston pumps to boost performance, in systems. Pooccas commitment to top notch products. Fledged assistance positions we as an ideal ally for companies, in need of dependable and effective piston pumps customized to meet their operational needs. By weighing the features of these pump varieties businesses can elevate their decision making capabilities and attain higher efficiency in their hydraulic setups.