Introduction to Gear Pumps in Petroleum and Chemical Industries

Gear Pumps are essential in the petroleum and chemical industries because they can efficiently manage viscous fluids. Renowned for their reliability, high efficiency, and capability to maintain consistent flow rates under different operating conditions, these pumps are favored in sectors where precision and durability are critical. Their mechanical simplicity and sturdy design make gear pumps a preferred choice.

Core Functions of Gear Pumps

The core function of Gear Pumps is to move fluid by enclosing it between the teeth of two or more gears and transferring it from the pump’s inlet to the outlet. This positive displacement mechanism ensures a precise amount of fluid is moved with each rotation of the gears. These pumps are particularly suited for high-pressure applications and can handle a wide range of viscosities, making them versatile for different industrial uses.

Importance of Reliability and Efficiency

In the petroleum and chemical industries, reliability and efficiency are paramount. Gear Pumps provide consistent and dependable performance, which is essential for processes that require uninterrupted operation. Their design minimizes downtime and reduces maintenance costs, thereby enhancing the overall efficiency of industrial operations. Moreover, their ability to operate under harsh conditions makes them indispensable in these industries.

Detailed Mechanisms of Gear Pumps

Internal Gear Pump Structure

Internal gear pumps feature one larger internal gear that engages with a smaller external gear, both housed within the pump casing. The unique structure allows the pump to handle thick, viscous fluids with ease. The fluid is trapped between the gears and moved smoothly to the discharge side, ensuring steady flow and high-pressure capabilities. This design is particularly useful in applications requiring high volumetric efficiency and low noise levels.

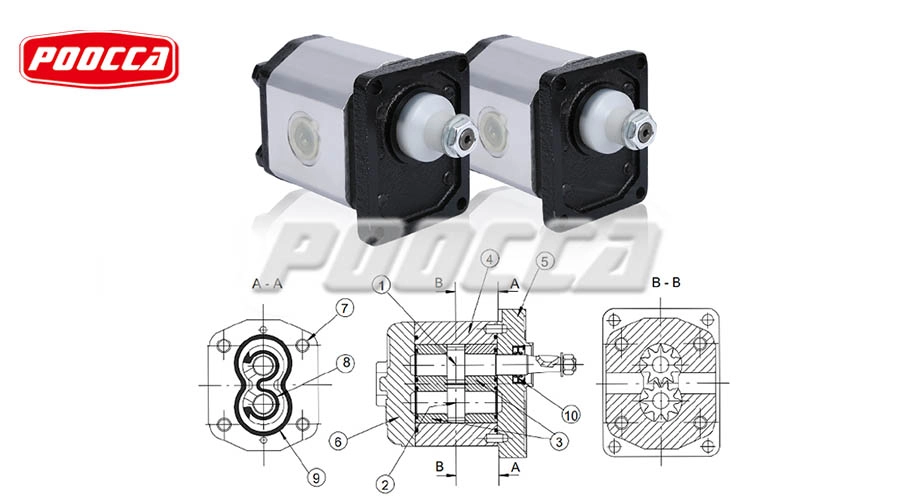

External Gear Pump Structure

External gear pumps are designed with two identical gears that mesh together within a sealed casing. When these gears rotate, they generate a vacuum that draws fluid into the pump. The fluid is then transported around the circumference of the gears to the outlet. This particular type of gear pump is frequently employed in situations requiring precise flow measurement and control. Additionally, their sturdy construction allows them to withstand higher pressures and handle more abrasive fluids compared to other types of pumps.

Factors Affecting Performance

Viscosity of the Fluid

The viscosity of the fluid being pumped significantly affects the performance of Gear Pumps. Higher viscosity fluids require more power to move and can lead to increased wear on pump components. Hence, proper selection of gear materials and pump design is crucial for efficient operation.

Operating Temperature

Operating temperature is another critical factor influencing the efficiency of Gear Pumps. Extreme temperatures can affect both the fluid properties and the materials of the pump. Proper thermal management, including cooling mechanisms and material selection, ensures optimal performance and longevity of the pump.

Maintenance Practices

Regular maintenance practices are essential for the optimal performance of Gear Pumps. Periodic inspection and replacement of worn-out parts, such as gears and seals, help in sustaining the pump’s efficiency. Employing preventive maintenance strategies reduces unexpected downtimes and extends the service life of the pump.

Advantages of Using Gear Pumps

High Pressure Capabilities

Gear Pumps are known for their ability to generate high pressures, making them ideal for applications that necessitate pumping against considerable resistance. This capability to manage high-pressure operations ensures their suitability for various challenging environments within the petroleum and chemical industries.

Consistent Flow Rates

One of the notable advantages of Gear Pumps is their ability to maintain consistent flow rates regardless of the pressure conditions. This characteristic is crucial in processes that demand precision and constant fluid delivery, such as chemical dosing and fuel injection systems.

Ease of Operation and Maintenance

Gear Pumps are designed for ease of operation and maintenance. Their simple mechanical construction and fewer moving parts reduce the likelihood of mechanical failure. Additionally, the straightforward design allows for easy disassembly and reassembly during maintenance, minimizing downtime.

Durability in Harsh Environments

The durability of Gear Pumps in harsh environments is a significant advantage in the petroleum and chemical industries. These pumps are built to withstand extreme operating conditions, including high temperatures, corrosive substances, and abrasive fluids. Their robust construction ensures long-term reliability and performance.

Applications in the Petroleum Industry

Extraction Processes

Upstream Operations

In upstream operations, Gear Pumps play a crucial role in the extraction and initial processing of crude oil. They are employed in drilling rigs and hydraulic fracturing activities to pump fluids at elevated pressures. Their capacity to manage viscous drilling muds and chemicals renders them indispensable in these applications.

Downstream Operations

In downstream operations, Gear Pumps are utilized for refining and processing crude oil into various products. They play a crucial role in the handling of heavy fuels, lubrication oil, and other hydrocarbon-based products. The precision and reliability of gear pumps ensure efficient handling and processing of these materials.

Transportation and Storage

Pipeline Transport

Gear Pumps are extensively used in pipeline transport for transferring petroleum products over long distances. Their ability to maintain consistent pressure and flow rates is vital for efficient pipeline operations, preventing blockages and ensuring smooth transportation of fluids.

Storage Facilities

In storage facilities, Gear Pumps are employed to move petroleum products into and out of tanks. Their reliability and high-pressure capabilities make them ideal for loading and unloading operations in storage terminals. The precise control over flow rates also aids in the accurate measurement and dispensing of stored fluids.

Applications in the Chemical Industry

Processing Chemicals and Compounds

Chemical Reaction Stages

Gear pumps are essential in various stages of chemical reactions, as they ensure the accurate and consistent delivery of reactants. Their capability to handle different viscosities and maintain a steady flow rate is vital for supporting the critical balance needed for optimal chemical reactions. These pumps are particularly beneficial in processes that require reliable fluid transfer to sustain reaction kinetics and product quality. Additionally, their predictable performance aids in scaling up laboratory processes to industrial levels without compromising consistency.

Mixing and Blending Applications

In the chemical industry, the mixing and blending of various compounds are integral processes to achieve desired product formulations. Gear Pumps contribute significantly to these applications by providing controlled fluid streams that enable proper mixing of components. Their accuracy in fluid transfer ensures that the ratios of different chemicals remain consistent throughout the process. This consistency is essential for maintaining the quality and homogeneity of the final product. Additionally, the robust design of these pumps minimizes contamination risks, thereby ensuring the purity of the chemicals being mixed or blended.

Handling Corrosive and Abrasive Fluids

Material Compatibility

One of the significant challenges in the chemical industry is the safe handling of corrosive and abrasive fluids. Gear Pumps address this challenge through the use of specialized materials like stainless steel, Hastelloy, and other corrosion-resistant alloys. The choice of material compatibility ensures that the pumps can withstand the harsh chemical environments, reducing wear and tear and extending the pump’s lifespan. By selecting materials that resist corrosion, industries can achieve uninterrupted operations and minimize maintenance costs.

Specialized Pump Designs

To cope with the demanding requirements of handling abrasive and corrosive fluids, Gear Pumps often feature specialized designs. For instance, pumps with hardened or coated gears are employed to resist abrasion, while those made from corrosion-resistant materials like PTFE or ceramic-lined components are used for corrosive fluids. These specialized designs not only enhance the durability of the pumps but also improve their efficiency by preventing leakage and other issues associated with corrosive wear. The integration of these tailored designs makes Gear Pumps indispensable for various demanding applications in the chemical industry.

Innovations in Gear Pump Technology by POOCCA

Introduction to POOCCA

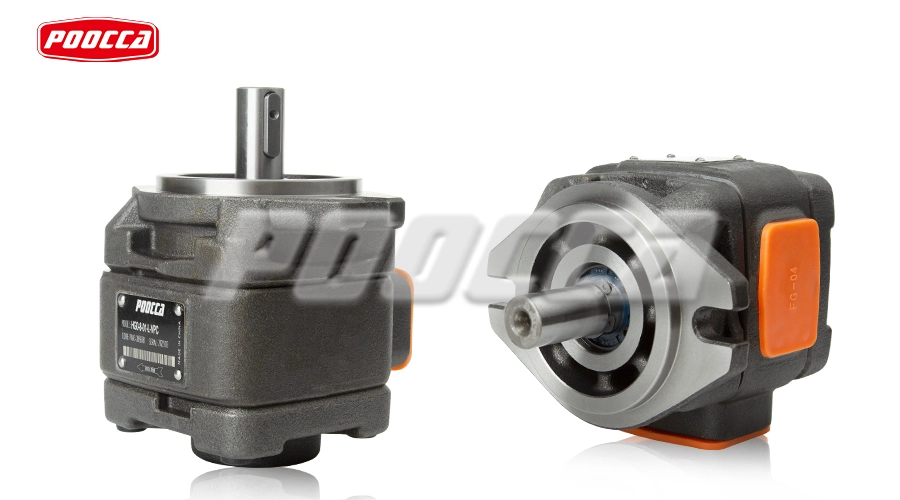

Company Overview

POOCCA stands out as a distinguished leader in the production of Gear Pumps, celebrated for our dedication to quality and innovation. With many years of experience, we has carved out a significant presence in both the petroleum and chemical sectors. POOCCA‘s wide array of products meets various industrial demands, offering solutions that boost efficiency and dependability.

Mission and Vision

POOCCA‘s mission is to drive industrial progress through innovative pumping solutions that meet the highest standards of performance and durability. We envisions becoming a global benchmark for technology and sustainability in the pumping industry. By continuously investing in research and development, POOCCA aims to pioneer advancements that address modern industrial challenges.

Technological Advancements

Improved Material Composition

POOCCA has made significant strides in improving the material composition of Gear Pumps. By incorporating advanced alloys and composite materials, we has enhanced the pumps’ resistance to wear and corrosion. These material enhancements ensure that the pumps can operate efficiently under high-stress conditions, reducing maintenance frequency and costs. The use of innovative materials also allows for better thermal management, further improving the longevity and performance of the pumps.

Future Prospects for Gear Pumps in Industrial Applications

The future of Gear Pumps in industrial applications appears bright, fueled by ongoing advancements in both technology and material science. As various industries continue to evolve, there will be a growing demand for pumping solutions that are not only efficient and reliable but also versatile. Innovations like smart monitoring systems and enhanced material compositions are poised to significantly boost the performance and durability of gear pumps. This will make them even more essential in operations within the petroleum and chemical sectors. Additionally, the drive towards sustainability and energy efficiency will encourage the creation of more environmentally friendly and cost-effective pump designs. With companies such as POOCCA at the forefront of innovation, the capabilities and uses of gear pumps are expected to broaden, solidifying their importance as key components in industrial processes.

In conclusion, Gear Pumps are indispensable in the petroleum and chemical industries due to their ability to handle a wide range of fluids under varying conditions, ensuring reliable and efficient operations. Their ongoing technological advancements and future prospects promise further innovation and enhanced performance, making them a key player in industrial fluid handling applications.