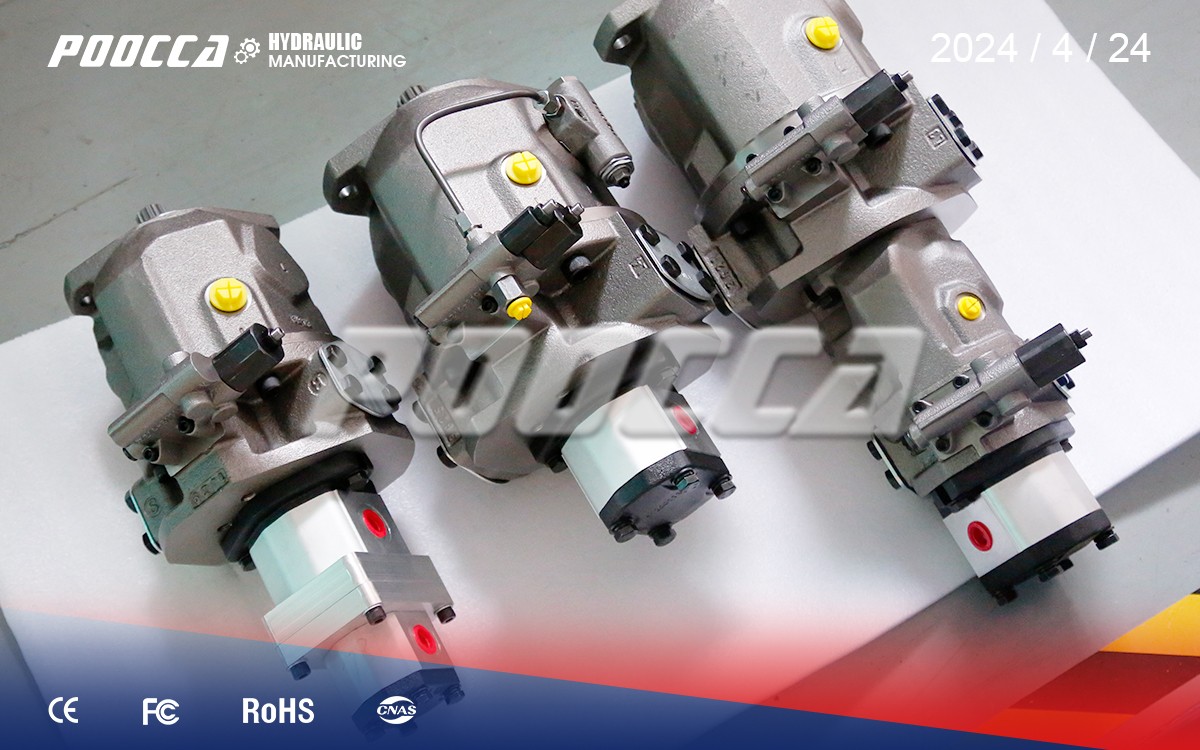

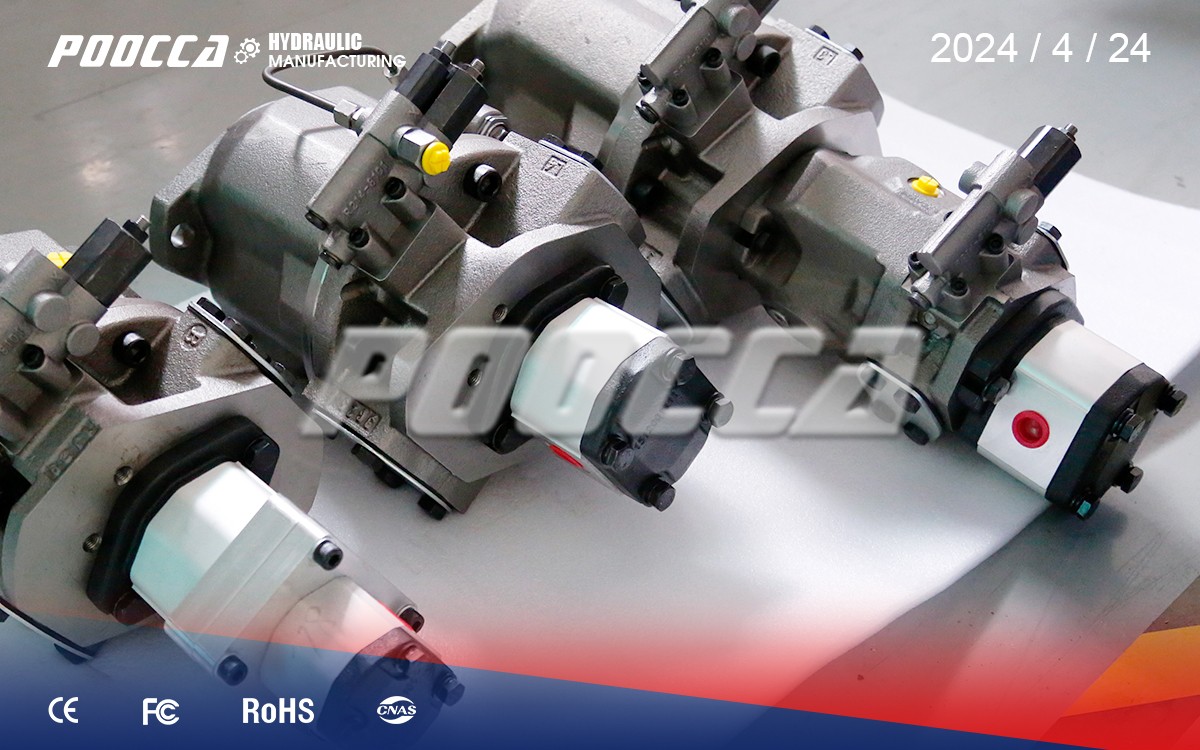

Thank you very much for the trust of the Mexican customer. In March, he found us and said that he needed 100 hydraulic tandem pumps. The following hydraulic piston pump tandem gear pump is our product to be released in April.

Piston pumps like this are common, so how much do you know about this product?

In hydraulic systems, the series connection of piston pumps and gear pumps is a common configuration used to improve the flexibility and efficiency of the system. This configuration combines the high-pressure capability of the piston pump and the stable flow output of the gear pump, and is suitable for hydraulic systems that require multi-level pressure and multi-functions. Here is some information about the series connection of piston pumps and gear pumps:

1. Characteristics of piston pump

High-pressure output: The piston pump is able to produce high-pressure output and is suitable for applications that require high pressure.

High efficiency: Provides higher efficiency, especially in applications that require precise control.

Variable flow: By adjusting the piston stroke, the piston pump can achieve variable flow output.

2. Characteristics of gear pump

Simple structure: The gear pump is simple in design, easy to maintain, and suitable for continuous operation.

Stable output: Provides stable flow and pressure output, suitable for general hydraulic systems.

Cost-effectiveness: Gear pumps are generally more economical than piston pumps and are suitable for projects with limited budgets.

3. Advantages of connecting piston pump and gear pump in series

Multi-level pressure: By connecting piston pumps and gear pumps in series, multi-level pressure output can be achieved in the system to meet different pressure requirements.

Flexibility: This configuration can provide flexible flow and pressure control and is suitable for complex systems that require different operating modes.

Efficiency improvement: When the system load changes, the piston pump can provide high-pressure output, while the gear pump maintains a stable flow, thereby improving the overall system efficiency.

If you have any needs, please contact Poocca hydraulic manufacturer and we will respond to you as soon as possible.

4. Implementation steps of series connection

Choose the right pump:

Make sure the flow and pressure range of the piston pump and gear pump are suitable for your application requirements.

Choose the appropriate pump specifications and models according to specific needs.

Connection pipeline design:

Use high-quality pipes and joints to connect the piston pump and gear pump to ensure no leakage.

Design a reasonable pipeline layout to minimize pressure loss.

5. System debugging:

Start the system and observe the operating status of the piston pump and gear pump to ensure that the two work well together.

Make necessary adjustments to ensure that the system can operate normally under different load conditions.

6. Regular maintenance:

Regularly check and maintain the pump and piping system to ensure long-term stable operation.

Regularly replace the hydraulic oil and filter element according to the usage to keep the system clean and efficient.

7. Application

Industrial equipment: In industrial applications that require precise control and stable flow, such as machine tools and automated production lines.

Engineering machinery: Used in construction and mining equipment, providing efficient power and multi-functional operation.

Agricultural machinery: In agricultural equipment that requires different operating modes, such as combine harvesters and seeders.

Poocca Hydraulic Manufacturers offers a variety of models of piston pumps and gear pumps to meet various application needs. We are committed to providing customers with efficient and reliable hydraulic solutions to ensure the best performance and service life of the system.