Introduction to Hydraulic Pump Motors

Hydraulic pump motors play a pivotal role in various industries, powering a wide array of machinery and equipment. The global hydraulic pumps and motors market is projected to reach approximately $22.9 billion by 2028, exhibiting a steady compound annual growth rate (CAGR) of 4%. This underscores the significance of hydraulic motors in driving industrial operations across different sectors.

The Role of Hydraulic Motors in Industry

The demand for hydraulic pumps in the industrial sector is undergoing a gradual decline as manufacturing processes become more efficient. However, the cumulative growth of application industries continues to impact hydraulic pump demand significantly. Notably, the rising demand for hydraulic motors across various industries such as petrochemicals, aerospace, chemical, and marine is optimizing manufacturing processes and driving the global hydraulic motors market.

Overview of Hydraulic Pump Motor Technologies

The hydraulic pump market is categorized into industrial application and mobile application segments. In 2022, the mobile application segment dominated the market in terms of revenue. However, the industrial application segment is expected to witness higher CAGR growth during the forecast period. Moreover, within the global hydraulic motors market, piston motors hold the majority of the total market share due to their high efficiency and ability to handle high pressure.

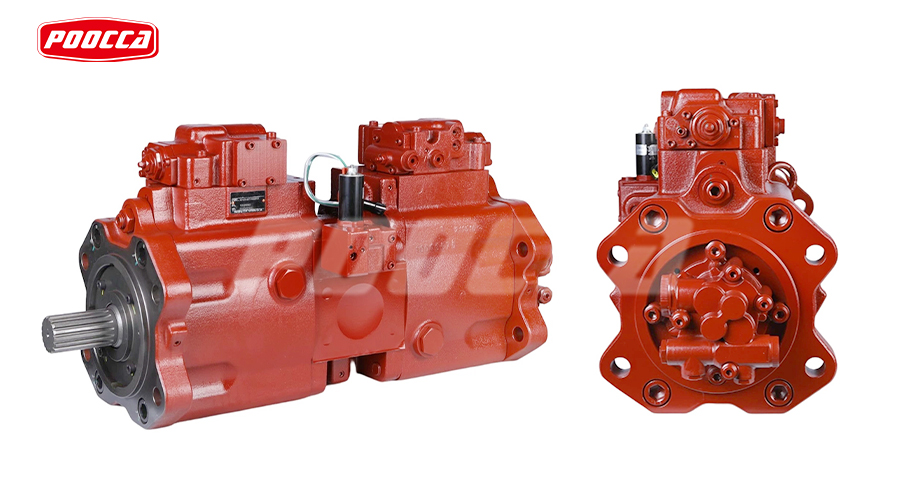

Understanding Hydraulic Piston Motors

Hydraulic piston motors are integral components in various industrial applications, leveraging the power of fluid dynamics to drive machinery and equipment. These motors utilize a unique mechanism of action to convert hydraulic pressure into mechanical energy, making them indispensable in diverse sectors such as manufacturing, construction, and aerospace.

Mechanism of Action in Piston Motors

The Reciprocating Movement

Piston hydraulic motors operate on the principle of reciprocating motion, where the pistons within the motor move back and forth in response to the pressurized hydraulic fluid. This reciprocating movement drives the rotation of the motor shaft, facilitating the transfer of energy to the connected machinery or equipment.

Fluid Displacement and Pressure

The operation of piston motors relies on efficient fluid displacement and pressure management. As pressurized hydraulic oil enters the motor’s chambers, it forces the pistons to move, generating rotational force. The ability to handle high-pressure environments makes piston motors suitable for heavy-duty applications that demand robust performance.

Advantages and Limitations

High Efficiency and Pressure Handling

One of the primary advantages of hydraulic piston motors is their exceptional efficiency in converting hydraulic energy into mechanical work. Their design allows for precise control over fluid flow and pressure, resulting in optimal performance across varying operational conditions. Additionally, these motors exhibit remarkable resilience in high-pressure settings, making them ideal for applications requiring substantial power output.

Considerations for Use

While piston motors offer impressive efficiency and pressure handling capabilities, certain considerations must be taken into account when deploying them in specific applications. Factors such as maintenance requirements, initial investment costs, and compatibility with varying operating conditions should be carefully evaluated to ensure seamless integration within industrial systems.

The innovative designs outlined in patents highlight advancements in piston motor technology, emphasizing features such as multi-capacity functionality and enhanced reliability under high loads and rotational speeds. These developments underscore the continuous evolution of hydraulic pump motor technologies to meet diverse industry demands.

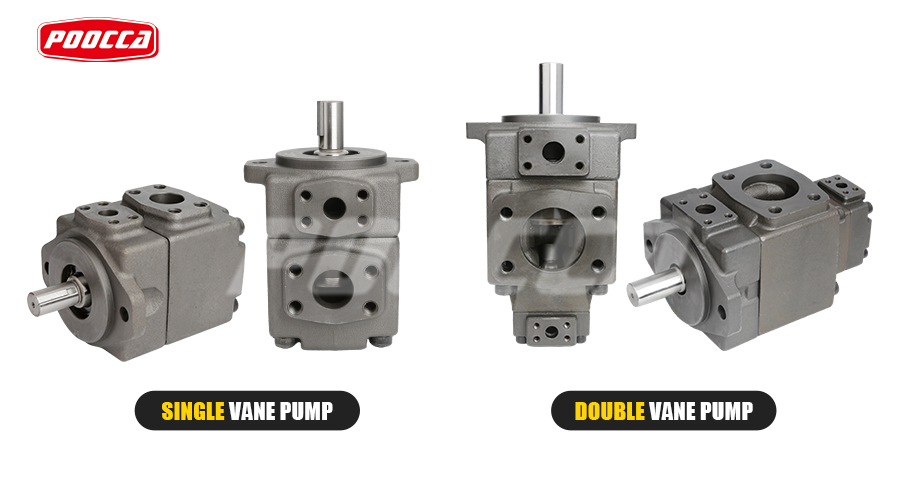

Exploring Hydraulic Vane Motors

Hydraulic vane motors are fundamental components in numerous industrial applications, harnessing the potential of fluid dynamics to drive a wide range of machinery and equipment. These motors operate on a distinct principle, utilizing rotating vanes to convert hydraulic pressure into mechanical energy, thereby fulfilling critical roles across diverse sectors such as manufacturing, automotive, and marine.

The Functioning Principle of Vane Motors

Rotating Vanes and Pumping Action

Vane motors employ a unique mechanism where vanes mounted on a slotted rotor create distinct compartments within the cam ring as the shaft rotates. As pressurized hydraulic fluid enters the motor, it fills these compartments, causing the vanes to move radially and generate rotational force. This pumping action facilitates the conversion of hydraulic energy into mechanical work, driving the motion of connected machinery and equipment.

Fluid Dynamics in Vane Motors

The operation of hydraulic vane motors is characterized by balanced pressures introduced to the cam ring’s contours through radial grooves and holes in the vanes. This equilibrium ensures efficient fluid displacement and rotational force generation, enabling vane motors to deliver consistent performance across varying operational conditions. Furthermore, vane motors are known for their ability to develop starting torque even at zero speed, enhancing their suitability for applications requiring precise control over motion initiation.

Benefits and Drawbacks

Quiet Operation and Longevity

One notable advantage of vane motors is their quiet operation, making them suitable for applications where noise reduction is a priority. The inherent design of vane motors minimizes operational noise levels, contributing to a more conducive working environment in industrial settings. Additionally, these motors are recognized for their longevity under specific operating conditions, providing reliable performance over extended periods with minimal maintenance requirements.

Application Suitability

Vane motors exhibit versatility in various applications due to their compact design and efficient power-to-weight ratio. They are commonly utilized in hand-held power tools such as drills, grinders, and sanders; mixers and agitators for liquids and viscous materials; pumps for transferring fluids or gases; actuators for valve automation and control; as well as food processing equipment such as mixers, blenders, and slicers. Their ease of maintenance further enhances their suitability for diverse industrial settings.

The best kind of air motor relies on a number of variables including design considerations, operating circumstances, and application requirements. While vane air motors are generally regarded as being dependable and easy to use with good operating efficiencies they may not be suitable for all applications due to factors such as limited low-speed capability.

POOCCA Hydraulic, established in 1997, is a comprehensive hydraulic service company that specializes in the research and development, manufacturing, maintenance, and sales of hydraulic pumps, motors, valves, and related parts. They have a strong reputation in the industry and have established strong corporate partnerships worldwide.

One of the key products offered by POOCCA Hydraulic is the hydraulic pump motor. These motors are designed to convert electrical or mechanical energy into hydraulic energy, driving the operation of hydraulic systems. The performance of these motors directly affects the efficiency and stability of the hydraulic systems they are part of.

POOCCA Hydraulic offers a wide range of hydraulic pump motors suitable for various applications. For instance, the Rexroth A2F Hydraulic Pump/Motor is an axially tapered piston unit in a fixed displacement oblique axis design. It can be used as a pump or motor in open or closed circuit systems, with the flow being proportional to drive speed and displacement when operating as a pump.

Comparative Analysis and Applications

Hydraulic Pump Motor Performance Comparison

When comparing hydraulic piston motors and vane motors, several key performance factors come into play, influencing their suitability for diverse industrial applications.

Efficiency and Pressure Capabilities

Piston motors are renowned for their exceptional efficiency, outperforming other hydraulic motor types such as vane motors. They possess the ability to adjust displacement, providing precise speed and torque control across varying operating conditions. This feature makes them highly adaptable to the dynamic demands of industrial processes, contributing to enhanced operational efficiency. Moreover, piston motors exhibit robustness and longevity even in challenging environments, minimizing costly downtime and ensuring reliable performance where operational continuity is paramount.

On the other hand, vane motors offer good operating efficiencies but generally fall short of the high efficiency levels achieved by piston motors. While they provide reliable performance in specific applications, their energy consumption may be comparatively higher when compared to piston motors. Additionally, the service life of a vane motor typically tends to be shorter than that of a piston motor under similar operating conditions.

Noise Levels and Operational Life

In terms of noise levels, vane motors stand out for their quiet operation, making them well-suited for applications where noise reduction is a critical consideration. The inherent design of vane motors minimizes operational noise levels, fostering a more conducive working environment in industrial settings. Conversely, while piston motors may produce slightly more operational noise due to their reciprocating motion mechanism, they excel in delivering extended operational life with consistent performance.

Choosing the Right Motor for Your Application

Selecting the appropriate hydraulic pump motor entails careful consideration of various factors to align with specific application requirements and operational constraints.

Factors to Consider

When evaluating the choice between piston and vane motors for an application, factors such as energy efficiency, torque capabilities at different speeds, pressure handling capacity, and expected service life play pivotal roles in decision-making. Understanding the unique demands of the intended application enables informed selection based on performance attributes that directly impact operational effectiveness.

Real-world Application Scenarios

In real-world scenarios, hydraulic piston motors find widespread utilization in operations demanding high power output under substantial pressure requirements. Their high-speed capability coupled with a broad displacement range positions them as favorable choices for heavy-duty applications across industries such as manufacturing, construction equipment, and material handling systems.

Conversely, vane motors are often preferred in applications where noise reduction is imperative or where compact design and efficient power-to-weight ratio are essential considerations. These include handheld power tools like drills and grinders; mixers and agitators for liquids; pumps for fluid or gas transfer; actuators for valve automation; as well as food processing equipment requiring precision control over motion initiation.

By carefully assessing these factors alongside real-world application scenarios, industry professionals can make informed decisions regarding the selection of hydraulic pump motors best suited to meet their specific operational needs.

Conclusion

Summarizing Key Takeaways

In conclusion, the comparison between hydraulic piston motors and vane motors reveals distinct performance attributes and application suitability that cater to diverse industrial needs. The pivotal role of hydraulic pump motors in driving machinery and equipment across sectors underscores their significance in optimizing manufacturing processes and operational efficiency.

Performance Attributes:

- Efficiency and Pressure Handling: Hydraulic piston motors stand out for their exceptional efficiency, precise speed control, and robust performance in high-pressure environments. On the other hand, vane motors offer good operating efficiencies with quiet operation and longevity under specific conditions.

- Noise Levels and Operational Life: Vane motors excel in minimizing operational noise levels, contributing to a conducive working environment. Meanwhile, piston motors deliver extended operational life with consistent performance.

Application Suitability:

- Heavy-duty Applications: Hydraulic piston motors find widespread utilization in operations demanding high power output under substantial pressure requirements across industries such as manufacturing, construction equipment, and material handling systems.

- Noise-sensitive Environments: Vane motors are often preferred in applications where noise reduction is imperative or where compact design and efficient power-to-weight ratio are essential considerations.

Future Outlook on Hydraulic Pump Motors

Looking ahead, the evolution of hydraulic pump motor technologies is poised to continue, driven by the ongoing demand for enhanced energy efficiency, reduced environmental impact, and advanced performance capabilities. The future outlook on hydraulic pump motors encompasses:

- Technological Advancements: Anticipated innovations in both piston and vane motor designs to further optimize energy conversion efficiency while addressing specific industry demands.

- Sustainable Solutions: Embracing eco-friendly materials and manufacturing processes to develop hydraulic pump motors that align with sustainability goals without compromising performance.

- Application-specific Customization: Tailoring hydraulic pump motor solutions to meet the evolving needs of diverse industries through customized designs catering to specific application requirements.

As industries adapt to evolving market dynamics and regulatory frameworks, the integration of advanced hydraulic pump motor technologies will play a pivotal role in enhancing operational productivity while prioritizing environmental stewardship.

In essence, the comparative analysis serves as a valuable guide for industry professionals seeking to make informed decisions regarding the selection of hydraulic pump motors best suited to meet their specific operational needs. By understanding the nuanced advantages and limitations of each motor type alongside real-world application scenarios, businesses can strategically leverage these technologies for sustained operational excellence.