Understanding Hydraulic Piston Pumps in Construction

Hydraulic piston pumps play a pivotal role in powering heavy machinery and equipment within the construction industry. These pumps are integral components that enable the efficient operation of various construction vehicles, such as excavators, cranes, and bulldozers.

What is a Hydraulic Piston Pump?

Hydraulic piston pumps are engineered devices that transform mechanical power into hydraulic energy, a process pivotal for generating considerable force. This force is crucial in powering heavy machinery used in construction projects. Fundamentally, these pumps operate by employing reciprocating pistons to pressurize hydraulic fluid, establishing a reliable and potent source of energy. Within the context of construction, hydraulic piston pumps are indispensable as they supply the requisite force for tasks such as lifting, excavating, and transporting materials across various project sites.

Basic Functionality and Use in Construction

The primary function of hydraulic piston pumps in construction is to deliver high-pressure fluid to various hydraulic motors or cylinders. This process enables the smooth and controlled movement of heavy equipment, enhancing operational precision and safety on construction sites.

The Role of Hydraulic Piston Pumps in Heavy Machinery

Hydraulic piston pumps serve as the driving force behind heavy machinery used in construction activities. Their ability to generate significant power facilitates the seamless execution of tasks that require substantial force, contributing to the overall efficiency and productivity of construction projects.

The Advantages of Using Hydraulic Piston Pumps

Efficiency and Power

One of the key advantages of hydraulic piston pumps is their exceptional efficiency in converting mechanical power into hydraulic energy. With an efficiency range between 70-95%, these pumps provide a reliable source of power for heavy machinery while minimizing energy wastage.

Versatility in Construction Projects

Hydraulic piston pumps offer unparalleled versatility in addressing diverse requirements across construction projects. Their adaptability allows for seamless integration with different types of heavy machinery, making them indispensable assets for various applications within the construction industry.

The global aftermarket for hydraulic pumps is expected to reach a valuation of US$ 16.3 billion by 2031, indicating their significant role in sustaining the operational capabilities of construction equipment.

The Environmental Footprint of Hydraulic Piston Pumps

Hydraulic piston pumps, while essential for powering heavy machinery in construction, also have a notable environmental footprint that warrants careful consideration. Understanding the ecological impact of these pumps is crucial for promoting sustainable practices within the construction industry.

Energy Consumption and Carbon Emissions

The Cost of High Pressure and Rapid Cycling

The functioning of hydraulic piston pumps typically entails operating under high pressure and at an accelerated cycle rate. This increase in energy demand subsequently results in higher carbon emissions. It is imperative to address this issue in order to reduce the carbon footprint linked to the use of hydraulic piston pumps in construction endeavors.

Quantifying the Carbon Footprint in Construction

Quantifying the carbon footprint attributable to hydraulic piston pumps in construction entails assessing their energy consumption patterns and corresponding emissions. This evaluation provides valuable insights into areas where improvements can be made to minimize environmental impact while maintaining operational efficiency.

In comparison with alternative technologies, hydraulic piston pumps are witnessing significant technological advancements aimed at enhancing efficiency and minimizing environmental impact. The market is experiencing a shift towards energy-efficient hydraulic systems to reduce overall operating costs and environmental impact. Additionally, heightened consciousness regarding environmental sustainability fuels the adoption of eco-friendly and renewable Variable Displacement Piston Pump solutions.

The future of the Hydraulic Piston Pumps Market looks promising, with factors such as growing industrialization, urbanization, and infrastructure development contributing to market growth. Moreover, there is a rising focus on sustainability and energy efficiency expected to drive demand for hydraulic piston pumps in coming years.

Heightened consciousness regarding environmental sustainability and imperative reduction of carbon emissions fuel adoption of eco-friendly and renewable Variable Displacement Piston Pump solutions. In contrast, axial piston pumps are known for their high efficiency, making them ideal for applications prioritizing energy savings.

Mitigating the Environmental Impact

As the construction industry continues to prioritize sustainability, mitigating the environmental impact of hydraulic piston pumps has become a focal point for industry professionals. Implementing proactive measures to minimize ecological repercussions is essential for promoting environmentally responsible construction practices.

Regular Maintenance and Proper Disposal

Best Practices for Minimizing Leaks and Spills

Adhering to stringent maintenance protocols is crucial for minimizing the occurrence of leaks and spills associated with hydraulic piston pumps. Regular inspections and preventive maintenance routines help identify potential issues before they escalate, reducing the risk of fluid leakage. Additionally, promptly addressing any signs of wear or damage in pump components can prevent unexpected failures that may lead to environmental contamination.

Implementing comprehensive training programs for equipment operators and maintenance personnel further enhances leak prevention efforts. Educating individuals on proper handling procedures, early leak detection, and immediate response protocols fosters a culture of vigilance towards environmental protection within construction teams.

The Importance of Recycling Hydraulic Fluids

Recycling hydraulic fluids presents an opportunity to minimize waste generation while promoting sustainable resource management. Establishing dedicated recycling processes for used hydraulic fluids enables their purification and reuse, thereby reducing the demand for new fluid inputs. This practice not only conserves natural resources but also diminishes the likelihood of improper disposal, safeguarding ecosystems from potential harm.

Integrating efficient filtration systems into hydraulic equipment facilitates continuous fluid purification, extending the operational lifespan of hydraulic fluids. By incorporating advanced filtration technologies, construction companies can optimize resource utilization and contribute to eco-friendly practices in hydraulic system maintenance.

Developing More Efficient and Eco-friendly Systems

The Role of Sustainable Construction Practices

Embracing sustainable construction practices complements efforts to mitigate the environmental impact of hydraulic piston pumps. Integrating eco-friendly building materials, optimizing energy-efficient designs, and prioritizing renewable energy sources collectively contribute to a greener construction ecosystem. Moreover, implementing modern construction techniques that emphasize minimal waste generation and enhanced resource utilization aligns with broader sustainability objectives within the industry.

By fostering collaboration between stakeholders across the construction supply chain, from manufacturers to project developers, sustainable practices can be seamlessly integrated into project lifecycles. This holistic approach ensures that environmental considerations remain central throughout all construction phases, reinforcing long-term ecological stewardship within the built environment.

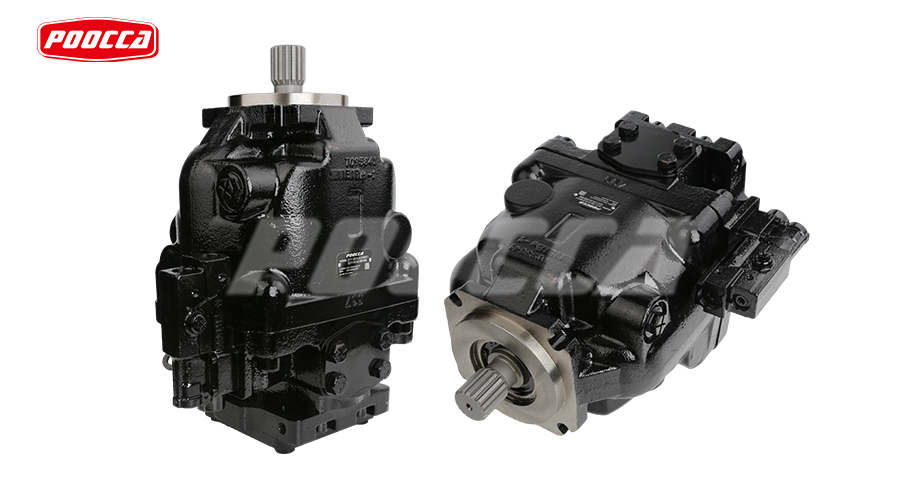

Established in 1997, POOCCA Hydraulic is a well-rounded hydraulic service company that provides a broad spectrum of hydraulic products, including piston pumps. These pumps are highly regarded for their effectiveness and dependability in a variety of hydraulic systems.

One of the popular piston pumps offered by POOCCA is the Rexroth A8VO Piston Pump. This variable displacement piston pump is designed for open circuit applications. It has displacements ranging from 55 to 200 cm3, a nominal pressure of 350 bar, and a peak pressure of 400 bar. The pump is designed for direct mounting on diesel engine flywheel housing and features proportional flow regulation.

Another notable product is the Eaton Vickers PVH Piston Pump. This high-performance piston pump is available in various sizes, with a geometric displacement of up to 141.1 cm3/r and a rated pressure of 250 bar. It is designed for versatile applications and features a compact and heavy-duty construction.

The Future of Green Construction

As the construction industry continues to evolve, there is a noticeable shift towards sustainability and environmentally conscious practices. This transition is driven by emerging trends and technologies that aim to reduce the ecological footprint of construction activities while enhancing operational efficiency.

The Shift Towards Sustainability in Construction

Emerging Trends and Technologies

The global hydraulic piston pumps market is experiencing several emerging trends that align with the successful integration of green hydraulic piston pump technologies in construction. One major trend involves the shift towards energy-efficient hydraulic systems to reduce overall operating costs and environmental impact. Additionally, there is a growing demand for smart and connected hydraulic pumps that offer real-time monitoring and predictive maintenance capabilities. The market is also witnessing a rise in demand for innovative hydraulic piston pump designs that offer higher efficiency and performance. Furthermore, there is a trend towards the integration of digital technologies such as IoT and automation to enhance the overall functionality of hydraulic piston pumps.

These trends signify a concerted effort to embrace sustainable solutions within the construction sector, emphasizing the adoption of advanced technologies that prioritize energy efficiency and environmental responsibility.

The Importance of Green Certification and Standards

In line with the industry’s commitment to sustainability, there is an increasing emphasis on obtaining green certifications and adhering to stringent environmental standards. Construction projects are seeking recognition through certifications such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method) to validate their commitment to eco-friendly practices. These certifications not only demonstrate compliance with established environmental benchmarks but also showcase a dedication to minimizing resource consumption, reducing waste generation, and mitigating environmental impact throughout project lifecycles.

Furthermore, adherence to green building standards ensures that construction endeavors align with regulatory requirements while contributing positively to broader sustainability objectives. By integrating green certification processes into project planning and execution, construction professionals can effectively promote environmentally responsible practices within the built environment.

The Role of Hydraulic Piston Pumps in Sustainable Construction

Case Studies and Success Stories

Several case studies underscore the successful integration of green hydraulic piston pump technologies in sustainable construction projects. For instance, advancements in hydraulic pump design have facilitated significant improvements in energy efficiency, leading to reduced carbon emissions without compromising operational performance. Projects leveraging these innovative pump technologies have demonstrated substantial reductions in energy consumption while maintaining high levels of productivity across diverse construction applications.

Moreover, the implementation of smart hydraulic systems equipped with real-time monitoring capabilities has enabled proactive maintenance interventions, resulting in enhanced equipment reliability and longevity. These success stories highlight how forward-thinking construction initiatives are embracing eco-friendly hydraulic solutions to achieve sustainable outcomes while meeting operational demands effectively.

Future Prospects and Challenges

Looking ahead, the future prospects for green construction are promising as industries continue to prioritize sustainable development practices. The integration of advanced hydraulic piston pump technologies will play a pivotal role in driving this momentum forward by offering efficient power solutions with minimal environmental impact. However, challenges such as intensifying competition, fluctuating raw material prices, and regulatory hurdles regarding environmental regulations pose ongoing considerations for industry stakeholders seeking to advance sustainable construction practices.

Navigating these challenges requires collaborative efforts among manufacturers, developers, regulatory bodies, and industry professionals to foster innovation while ensuring compliance with evolving environmental standards. By addressing these challenges proactively, the construction sector can further solidify its commitment to sustainable development while embracing cutting-edge technologies that uphold ecological stewardship.

Conclusion

Recap of Key Points

Throughout this exploration of hydraulic piston pumps in construction, it becomes evident that these essential components play a crucial role in powering heavy machinery and equipment, contributing to the efficiency and productivity of construction projects. The basic functionality of hydraulic piston pumps involves converting mechanical power into hydraulic energy, enabling the smooth operation of various construction vehicles. Their advantages include exceptional efficiency in power conversion and unparalleled versatility across diverse construction applications.

The environmental footprint of hydraulic piston pumps is a significant consideration, encompassing aspects such as hydraulic fluid consumption, pollution from leaks and spills, energy consumption, and carbon emissions. Mitigating these environmental impacts requires proactive measures such as regular maintenance, proper disposal practices, recycling of hydraulic fluids, and the development of more efficient and eco-friendly systems.

The Path Forward for the Construction Industry

Embracing Green Technologies

Sustainability is becoming a top priority in the construction industry as companies recognize the positive impacts of green building initiatives. Increasing government regulations are demanding heightened environmental measures, placing more scrutiny on how projects are designed, constructed, and maintained. As more executives realize that sustainable choices are beneficial for business, engineering and construction companies are expected to set sustainability commitments and adopt sustainable practices into more aspects of their operations.

The Importance of Education and Awareness

The development of green technology is widely regarded as a beneficial approach to mitigating the environmental impact of human activities and addressing ecological challenges. Nevertheless, this advancement is not without its ethical dilemmas. Consequently, it is essential to enhance education and awareness about sustainable practices in the construction industry to facilitate the broad adoption of green technologies. By providing industry professionals with comprehensive knowledge of environmentally responsible practices and the ethical implications inherent in the development of green technologies, the construction sector can effectively contribute to a more sustainable future while maintaining high ethical standards.