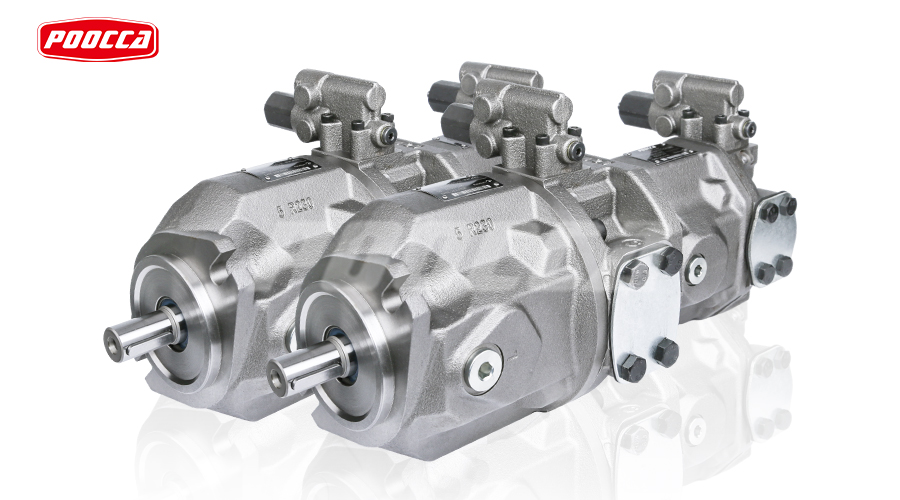

Axial piston pump is an important hydraulic transmission equipment, widely used in various industrial fields, such as machinery manufacturing, mining and so on. The following content will introduce the classification of axial piston pumps, basic structure, working principle, advantages, applications and maintenance and other knowledge.

Classification of axial piston pumps

The type of axial piston pump is the same as axial piston motor, also divided into straight axial piston pump and inclined axis axial piston pump.

The axial piston pump whose drive shaft is in line with the cylinder axis is called straight shaft type, because it relies on the tilt angle of the drive disk to adjust the flow, so it is also called swash plate type. Drive shaft and cylinder tilted at a certain angle of the axial piston pump is called inclined shaft type, it relies on the angle of the cylinder tilt to adjust the flow, so it is also known as swing cylinder type. The structure of straight shaft axial piston pump is simple, compact, high efficiency, can be used for higher pressure, the allowable rotational speed is also higher, but the plunger end and drive swash plate contact parts are weak, not resistant to shock and vibration; it is good for oil suction, but the oil filtration precision requirements are high. Inclined-axis axial piston pump has good shock vibration resistance, the cylinder swing angle can be up to 25 °, the oil filtration precision requirements are lower, but its structure is complex, due to the cylinder swing occupies a large space, thus making the pump’s external dimensions become larger.

Basic structure of axial piston pump

Axial piston pump is mainly composed of pump body, cylinder, plunger, flow distribution disk, drive shaft and sealing device and other components. The pump body is the shell of the pump, used to support and fix other parts; the cylinder is equipped with a number of internal plunger holes, the plunger in the hole to do reciprocating motion; flow distribution disk is located at both ends of the cylinder, used to control the suction and discharge of the liquid; drive shaft through the drive device to drive the plunger for reciprocating motion; sealing device is used to prevent the leakage of liquid.

Working Principle of Axial Piston Pumps

Suction process

When the drive shaft drives the plunger to move backward, the volume between the plunger and the cylinder gradually increases, forming a negative pressure area. At this time, the suction port on the distribution disk opens, and the liquid is sucked into the space between the cylinder and the plunger under the effect of differential pressure. As the plunger continues to recede, the suction volume gradually increases, and when the plunger rotates to the highest position, the plunger hole has just finished sucking the oil and is about to be discharged outward.

Discharge process

When the drive shaft drives the plunger forward, the volume between the plunger and the cylinder gradually decreases, and the liquid is compressed and pushed to the discharge port on the distribution disk. As the plunger continues to move forward, the discharge volume gradually increases until the plunger moves to the front stop, the end of the discharge process. At this point, the pressure of the liquid at the discharge outlet reaches its maximum value and is transported through the pipeline to the place where it is needed.

In the working process of axial piston pumps, the flow distribution disk plays a key role. It realizes the continuous suction and discharge of liquid by precisely controlling the opening and closing of the suction and discharge ports. At the same time, the rotational speed and direction of the drive shaft determines the movement speed and direction of the plunger, which affects the flow rate and pressure of the pump.

Advantages of axial piston pumps

The working pressure, volumetric efficiency and total efficiency are the highest. Because the plunger and the cylinder bore are easy to process, the dimensional accuracy and surface quality can meet high requirements, so the fit precision is high, the oil leakage is small, and the working pressure that can be achieved is high, generally 20 to 40 MPa, up to 100 MPa.

The maximum power that can be transmitted. Because as long as the appropriate increase in plunger diameter or increase the amount of plunger, the flow rate increases. With high pressure and high flow, it can transmit high power.

Long service life and high power density. The main parts of the piston pump are pressurized, so that the material strength can be fully utilized, so the service life is longer, and the unit power quality is small.

Good two-way variable ability. Changing the stroke of the plunger can change the flow rate, easy to make a variety of variable type.

Application areas of axial piston pumps

Axial piston pumps are widely used in a number of industrial fields. In the field of machinery manufacturing, axial piston pumps can be used to drive various hydraulic actuators to realize the automatic control of machine tools; in mining, axial piston pumps can be used to drive hydraulic motors to realize the power transmission of mining equipment; in petrochemical industry, axial piston pumps can be used to transport a variety of corrosive mediums and high-temperature and high-pressure liquids.

Maintenance of axial piston pumps

In order to ensure the normal operation and extend the service life of the axial piston pump, regular maintenance and repair is required. It mainly includes the following aspects:

- Regularly check the integrity of the sealing device, if damaged, it should be replaced in time;

- Clean the inside of the pump body and cylinder to remove deposits and impurities;

- Check the wear and tear of the drive shaft and replace it if necessary;

- Check the wear and deformation of the flow distribution disk and repair or replace it promptly if there is any problem;

- Check and adjust the flow and pressure of the pump to ensure that it meets the working requirements.

Conclusion

According to the above introduction, the working principle of axial piston pump is based on the reciprocating movement of the piston in the cylinder to realize the suction and discharge of liquid. Through the introduction of it, we can better understand and apply the axial piston pump. Last but not the least, in practical application, users should choose the appropriate axial piston pump model and specifications according to specific needs, and strictly follow the operating procedures for use and maintenance to ensure its stable and reliable operation.

Poocca hydraulic manufacturer sells product brands including: Rexroth pump, Parker pump, Yuken pump, Danfoss Rexroth pump, etc. If you have any needs, please feel free to send your requirements and look forward to cooperating with you.