As an indispensable power transmission and control device in the modern industrial field, the efficient and stable operation of the hydraulic system is crucial for the normal operation of various mechanical equipment. In the hydraulic system, piston pump as a key power element, its performance directly affects the performance and stability of the entire system.

The working principle and structural characteristics of piston pump

Piston pump is a kind of volumetric hydraulic pump, its working principle is through the reciprocating movement of the piston in the cylinder to change the working volume, so as to realize the liquid intake and discharge. Specifically, when the piston moves backward, the working volume increases, forming a low-pressure area, the liquid is sucked into the pump; when the piston moves forward, the working volume decreases, forming a high-pressure area, the liquid is discharged from the pump. This reciprocating motion through the transmission mechanism (such as electric motors, internal combustion engines, etc.) drives, so that the pump continuously suction and discharge of liquid.

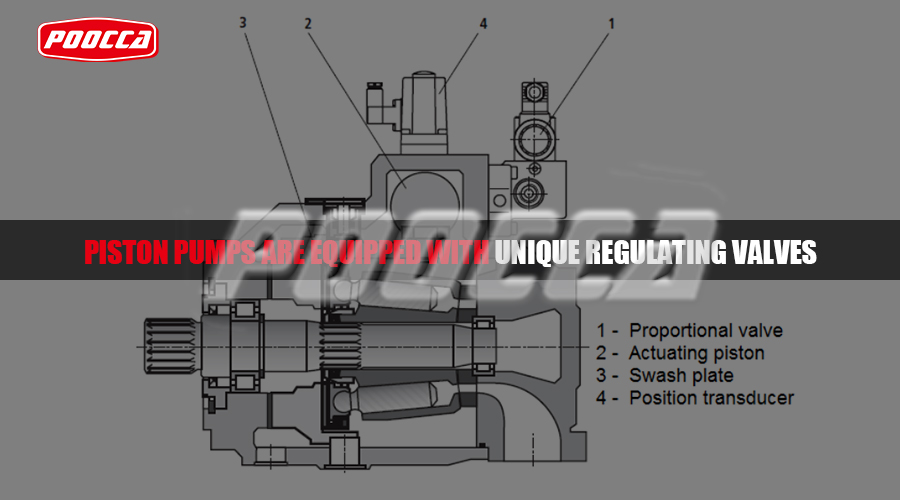

In terms of structure, piston pump is usually composed of pump body, piston, cylinder, flow distribution disk, drive shaft and other components. Among them, the pump body is the main part of the pump, which is used to accommodate the piston and cylinder; the piston is the core part of the pump, which realizes the suction and discharge of the liquid through its reciprocating motion; the cylinder cooperates with the piston to form the working volume; the flow distribution disk is used to control the inflow and outflow of the liquid; and the transmission shaft is responsible for transferring the external power to the piston.

Performance Advantages of Piston Pumps

Piston pumps have a number of performance advantages in hydraulic systems, making them the power element of choice for many applications.

First and foremost, piston pumps have high operating pressures and flow rates. Due to the special nature of its working principle, piston pumps are able to work stably at higher working pressure and provide larger flow rate to meet the needs of various complex working conditions.

Secondly, piston pumps have better pressure regulation performance. By adjusting the rotational speed of the drive mechanism or changing the stroke of the piston, the output pressure and flow rate of the pump can be easily adjusted to achieve precise control of the hydraulic system.

In addition, the piston pump has high efficiency and long service life. Its compact structure and few moving parts make the energy loss smaller and the efficiency higher; at the same time, due to the use of wear-resistant, corrosion-resistant materials and precision machining process, the service life of the pump can be extended.

Application of piston pumps in hydraulic systems

Piston pumps are widely used in hydraulic systems, covering almost all fields that require hydraulic power transmission and control. The following are some typical application scenarios:

In the field of construction machinery: In excavators, loaders, road rollers and other construction machinery, piston pumps are used as the power source of the hydraulic system to provide stable and reliable power support for various actuators.

Metallurgical equipment: In metallurgical equipment such as iron and steel smelting and non-ferrous metal processing, piston pumps are used to drive various hydraulic cylinders, motors and other actuators to realize precise control and efficient operation of the equipment.

Ship and ocean engineering field: In ship propulsion system, rudder system and lifting system of ocean platform, piston pumps play a key role to ensure the stable operation of ship and ocean engineering.

Agricultural machinery field: in tractors, harvesters and other agricultural machinery, piston pumps provide power for the hydraulic system to realize the automation and intelligent control of agricultural machinery.

Impact of piston pumps on hydraulic system performance

As the core component of the hydraulic system, the performance of the piston pump has a decisive impact on the operation of the entire system. In particular, a quality piston pump can ensure that the hydraulic system has the following advantages.

Performance efficiencies: The efficient use of piston pumps reduces energy losses from the hydraulic system and improves overall efficiency, thereby reducing energy and operating costs

Status: An all-around piston pump helps maintain constant pressure and flow in a hydraulic system, reducing variability and shock, and extending system life

Reliability: High-quality piston pumps have high friction and corrosion resistance, and are able to operate steadily for extended periods of time in harsh operating environments, improving the reliability of the hydraulic system.

Precision: The piston pump has excellent pressure regulation performance, in order to meet the performance requirements of high accuracy, in order to realize precise control of the fluid system.

Poocca hydraulic supplier‘s piston pumps have multiple displacements for you to choose from. A10VSO, A4VSO, PV, HYVA piston pumps, A11VLO, PVH pumps, etc. are all in stock. We look forward to your contact.

Conclusion

In summary, piston pump plays an important position and role in hydraulic system. Its excellent performance and versatility make the piston pump an indispensable component in a hydraulic system. Continuous scientific and technological advances and technical advances will further improve the performance of piston pumps, their application in water systems will be broader and deeper.