Exploring Fixed Displacement Hydraulic Pumps

Characteristics of Fixed Displacement Pumps

Fixed Displacement Hydraulic Pumps are recognized for their ease and dependability. These pumps have a steady flow rate. They push out a fixed amount of fluid each cycle. This trait makes their performance easy to predict. It’s helpful in setups where exact control isn’t needed. The build of fixed displacement pumps is usually tough. They can work well under high pressure and in rough settings. Their design often has fewer moving pieces than variable displacement pumps. This adds to their sturdiness and cuts down on upkeep needs.

Common Applications of Fixed Displacement Pumps

Fixed Displacement Hydraulic Pumps get used a lot where a steady flow is a must. You’ll spot them in factory machines, farm tools, and building vehicles. For example, these pumps are great for running hydraulic motors that move conveyor belts or other gear needing constant motion. Plus, they work in log splitters, snow plows, and other tools where the hydraulic system’s needs stay pretty even over time. The regular output of fixed displacement pumps fits systems that don’t need frequent tweaks or changing flow rates.

Considerations When Choosing Fixed Displacement Pumps

Picking Fixed Displacement Hydraulic Pumps means looking at a few things to get the best results. The top thing is knowing what your specific job needs, like the flow rate and pressure you want. You also need to think about the work setting. Fixed displacement pumps handle tough conditions well. But they might not suit jobs needing tight control or efficiency with shifting loads. Another point is the pump’s cost value. They’re often cheaper to buy due to their simple build. Still, check the full cost over time, including upkeep and energy use.

Understanding Variable Displacement Hydraulic Pumps

Features of Variable Displacement Pumps

Variable Displacement Hydraulic Pumps bring flexibility and savings by letting you tweak the flow rate and pressure based on what the system needs. Unlike fixed displacement pumps, they can change how much fluid they pump without adjusting the pump’s speed. This feature allows sharper control over hydraulic systems. It makes them perfect for jobs needing different outputs. These pumps usually have tricky parts like swash plates or cam rings that shift the displacement amount on the fly. Being able to adjust output cuts energy use and lifts system efficiency.

Common Applications of Variable Displacement Pumps

Variable Displacement Hydraulic Pumps show up a lot in fields where active control over fluid power matters. They’re widely used in mobile gear like excavators and loaders. These machines face changing loads that call for different power levels at different times. In factory settings, these pumps run injection molding machines and presses. Here, exact control over speed and force is needed at various stages. Also, variable displacement pumps get used in aerospace jobs where saving weight and boosting efficiency are top priorities.

Considerations When Choosing Variable Displacement Pumps

Choosing Variable Displacement Hydraulic Pumps means weighing a few big factors tied to performance and job needs. A key point is how complex your hydraulic system is. These pumps help when you need fine control over output. But they might cost more upfront due to their fancy design. You should also compare energy savings with possible upkeep demands. Variable displacement pumps have more parts that might need fixing over time. Lastly, check how they fit with your current setup. Make sure workers know how to handle the advanced controls. This affects how well they’ll work in your job.

By carefully looking at these points for each type—fixed versus variable—folks can pick the hydraulic pump that best matches their work needs. They can balance performance with cost value.

Making the Right Choice: Fixed vs. Variable Displacement Pumps

Evaluating Your Specific Needs

Deciding between Fixed and Variable Displacement Hydraulic Pumps takes a close look at your work demands. Start by figuring out your job’s nature. Does it need steady or changing flow rates? Fixed displacement pumps work fine for tasks with even, stable needs. Variable displacement pumps shine where loads shift and tight control is a must.

Think about the work setting too. Fixed displacement pumps do well in harsh spots thanks to their strong build. Variable displacement pumps save energy in systems with changing demands. Also, consider long-term costs. This includes the starting price, upkeep, and energy use. The system’s complexity and the skill needed to run it should steer your choice too.

Advantages and Limitations of Each Type

Fixed Displacement Hydraulic Pumps come with perks like simplicity, trustworthiness, and good pricing. Their basic design means fewer moving bits. This lowers upkeep needs and boosts toughness. But they can’t adjust flow rates easily. This might limit savings in systems with changing load needs.

Meanwhile, Variable Displacement Hydraulic Pumps give top-notch control over fluid power setups. They let you tweak flow rates and pressure as required. This flexibility boosts energy savings and performance in active jobs. The downside is their trickier build and higher starting cost. Their fancy parts might need more frequent fixes.

In the end, choosing between fixed and variable displacement pumps depends on weighing these pros against cons. Match them to your specific work needs.

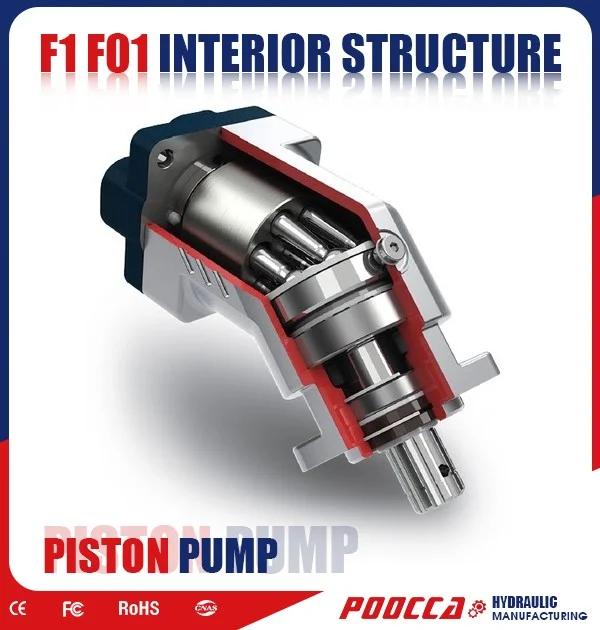

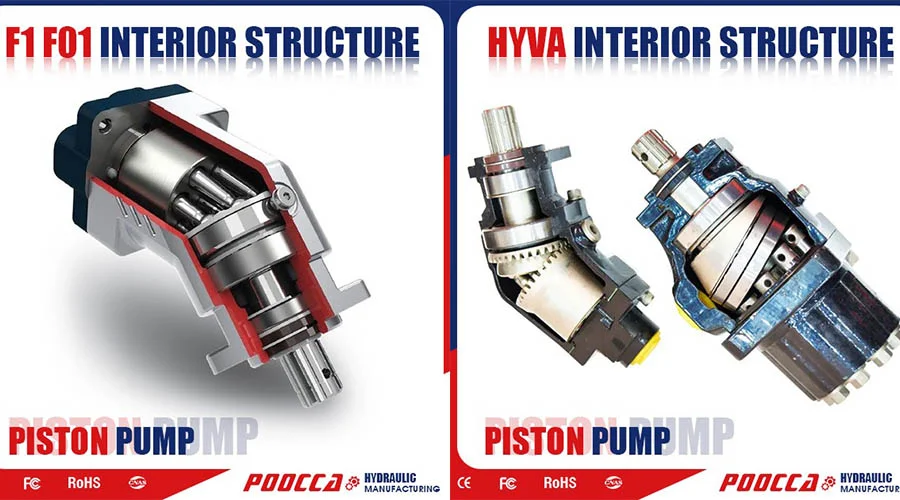

Discover POOCCA’s Customized Hydraulic Solutions

POOCCA focuses on tailored hydraulic answers. They offer Fixed and Variable Displacement Hydraulic Pumps built for strength and efficiency. Their fixed pumps deliver steady output. Their variable pumps give smooth flow and pressure tweaks for precise jobs. POOCCA’s tailoring services shape solutions to fit unique client wants. This lifts system performance and cost savings. With expert advice, smooth blending, and quality checks, POOCCA brings advanced hydraulic tech and personal service. They help industries hit top work results.